STAINS AND STRESSES IN TIPPING.

Page 139

Page 140

If you've noticed an error in this article please click here to report it so we can fix it.

Especial Strength Requisite in Frame and Springs, in Order to Combat the Effect of Tipping on the Vehicle.

By Maurice F. Edwards.

THE strains on commercial motor chassis fitted with tipping devices are considerably greater than, and of a different nature from, those associated with an ordinary flat lorry. The body of the latter naturally rests on the whole length of the chassis, and may, possibly, even add to its strength. But the case of the tipping wagon, is different in many respects, for it entails strains and stresses due to the special functions for which it is built. In recent years we have learnt much about these, and how to combat them. To the foreign and colonial buyer, in particular, this is valuable news, as showing that we in England are alive to every phase of "tipping "—that is, not only the gears therefor, but the general design necessary to forestall possible trouble. The user abroad has few handy conveniences for repair. He must have an outfit as near foolproof as possible, and, indeed, the same is demanded by buyers and drivers at home!

Whether the tipping gear be of the screw type at the front endof the body, or of hydraulic type with rams probably lifting at the centre of the body, the strains oa the chassis frame become intensified at certain points. The whole load gets borne practically by two points :—(a) The lifting gear, and (b) the hinged portion of the tipper or body. Obviously, as the body is elevated the weight becomes greater on the extreme end of the chassis frame. Hence the imperative fundamental necessity of a frame substantially constructed.

At an early stage of the tipping, in vehicles with the ram lifting at the centre of the body, the whole burden of load plus body literally devolves on the chassis at the point where the rams are fixed. As the angle of the body (during elevation) becomes greater, the weight gets distributed between the said point and the ends of the chassis frame. Therefore, special strength is indispensable in the rear portion of the chassis.

Extra Strength in the Springs Necessary.

Likewise, during the operation of tipping, the whole weight falls on the rear springs, so here, again, added strength is imperative. It is, indeed, now recognized practice to embody extra leaves wherever it is known that a chassis is being purchased for use with a tipper, as distinct from ordinary transport per flat lorry body. For example, instead of standard 13 leaves by 3 in., 15 plates are a desirable minimum.

Concerning bodies that tip sideways, a point demanding great eaiphasis and attention is this :—On a double

sided or three-way tipper, considerable stress has always to be borne (a) by one member of the chassis frame, and (b) by the road spring or wheel spring on that same side. Again, in the case of side-tipping, with central rams, there is also side-thrust to be taken into reckoning. Therefore, any chassis intended for side-tipping, whether this be by screws or rams, should have a tie-piece or cross-member at some point near the screws or rams to prevent the chassis frame being pushed apart or distorted. Any weakness here would impair the efficiency of the whole outfit, would soon sully a maker's reputation, and do harm to commercial motoring in general.

The Maudslay designers provide tile requisite extra strength by arranging for placing, underneath the ordinary chassis frame, an additional channel-section member ; and I might here observe that this wagon is capable of tipping 12 tons without distortion.

Some firms are placing, on top of the chassis, an angle piece, reaching from behind the driver's cab to the rear end of the chassis. This is an effective treatment; it is also a cheap and quick method of assuring that desideratum, extra stability, and it does not add greatly to the weight of the frame.

The procedure mentioned in the preceding paragraph is pursued by such eminent and experienced firms as Dennis,and Karrier, and also at my own works, when'.

we fit tipping gears to chassis which we deem to be in need of extra strength.

To summarize the need for " substantiability " in chassis, due to screws and rams being applied at points rather than to the extreme under-surfaces, 1 would put the matter thus :—Bodies niust be made strong, either at the works when new, or by subsequent addition; and these runners or " strengtheners " need to be of deep channel steel or of wood fitted with deep

filch plates. •

Let us consider next the cases where screw or hydraulic-ram apparatus is fitted behind the driver's cab. When the process of tipping begins, a fairly heavy strain is imposed on the chassis frame at what is probably its weakest point, viz., the centre. Of course, the ram or screw operating from this location does not require the same pressure as a screw or ram lifting at the centre of the body ; so that, for the endtipping wagon in this category, the same strengthening of frame would not be requisite.

When it conies to high-lift "tippers," still further and extremely thoughtful attention is demanded to this point of chassis-strength. For the first part of the lift (whilst the body is lifted horizontally) the whole of the weight is thrown somewhat rearwards. Then in the second movement, when the body actually begins to tip, the weight is still more thrown on the rear, putting practically the whole total of load and body on the extreme end of the chassis frame. Where this type of gear is employed—that is, high lift—I always feel the advisability, if not imperative necessity, of providing extra strength at the point so heavily taxed.

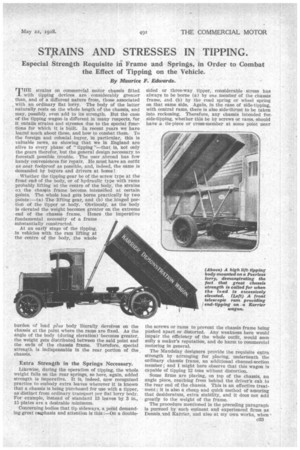

From the illustration (page 491), which, incidentally, is of an old Peerless, it will be appreciated readily that, when a heavy load is well elevated and then being tipped, there is a tremendous leverage exercised on the chassis.

Requisite Frame Strength Now Given.

It is a pleasure to remark at this juncture—and it is aa obkervation based on years of experience with countless makes of chassis—that most manufacturers now provide for more sturdiness in chassis construction than they did a few years ago; and, further, one discerns the fact that chassis frames are now made of steel with much higher tensile strength.• I have noted the progressive attention to this vital detail of sturdiness and gladly mention it ; but we still get some chassis to which reinforcements are needed and are given on the principle of "Safety First." This, however, must not be read as a criticism of any designers at big factories. Far from it. Indeed, if manufacturers always knew beforehand which of their standard type of frames would be wanted for tipping wagons, with the special strains and stresses to which these are

c3.4 liable, the factories es Se. could anticipate the needs of every As a matter of fact, the demand for " Uppers " has advanced to so marked a degree that. I believe certain manufacturers are making a special chassis for that class of work.

Commercial motors on tipping work are often subject to more severe usage than the regular transport vehicle, the latter generally having highways of more or less good surface upon which to operate, whereas the "tipper" goes on to waste grounds with rubbish, to housing estates with sand or bricks, invariably where there is no proper road—maybe ruts with stones and rubble tumbled in, or at best made with old railroad sleepers. Thus, apart from tipping work, the frames and road springs must be of super-strength.

No Risk of Overturning.

More than once have I been asked whether there is a possibility of a tipping wagon overbalancing itself, particularly, with a high-lift apparatus tipping at the back. Some amongst us may smile. Has anybody ever heard of such a mishap? For myself, never ; not even where emptying takes place on a sloping piece of land. Still, it is a legitimate question for our corporation and other friends to ask, and I always treat it respectfully.

The reason one never hears of such an overturning or overbalancing is this : the leverage from the centre of the rear axle to the end of the frame is not sufficient to allow the load to overbalance the vehicle and lift the front wheels off the ground. Therefore, one may assert that there is no danger of overbalancing. In fact, chassis frames for tipping wagons are invariably shorter than those used for omnibuses, or even for ordinary flat bodies used on haulage work. This alone contributes to make the frame less • liable to distortion and reduces the chance of overbalancing.

I have dwelt so far mainly on the need for assured strength in the chassis frame and springs. I have been asked : What about the

channel-section wheels? Obviously, just as frame chassis frame. and spring on one side bear big

weight during tipping, so will the wheels on the same side (and, incidentally, the tyre). But wheels seem to have been made always on the Sohn Bull principle, with strength for any emergency and then some to spare. I have never heard of a case of wheel collapse.

The Great Value of the Six-wheeler.

Six-wheelers are advancing in favour for all types of work. They are now being utilized for "tippers." They give a really rigid frame and, I consider, ought to he an ideal Ope, as the strains (now falling on one axle and two twin rear wheels and two road springs) are distributed over four wheels and springs and twin axles. The six-wheeler has advantages in easier manipulation on ground where, for instance, building is in progress and roads non-existent ; or about brick-making kilns or refuse tips, etc. It enables a longer type of body to be used—a meritorious point, for a given quantity of material may be conveyed to a difficult tip with much fewer journeys.

As vehicles are often overloaded, the figures quoted will give an idea of what power can really be applied to the chassis frame—which has to endure whatever thrust is exerted by the ram.

With this in mind, and having had such a wide experience with many makes of vehicle, I must gladly reiterate my observation that most firms recognize the need for frame sturdiness; but I say it subject to any variations, or addition of extra channels, sometimes deemed desirable, as mentioned in other paragraphs.