LINK WITH THE FUTURE

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

VBG plans to revolutionise drawbar coupling with a new automated system. Kevin Swallow travelled to Sweden to see it in action.

Swedish coupling manufacturer VBG is so excited by the potential of its latest automated Multi Function Coupling (114FC) that it is asking manufacturers and operators to examine the system and find out how it could benefit them.

Gunnar Nyvaller, area sales manager for the Vanersborg-based company,says:"We want to see what the capability of it is. VlIG can only offer the product to the market -we need to see what operators can really use it for.

The automated coupling is said to have benefits for health and safety, as well as saving time and eradicating a dirty job."It is fully automated; the driver can activate it from the safety of his own cab.The process takes seconds," says Nyvaller."It has been trialled for the past year by a logging company, and further tests are planned over the next 12 months with 20 more vehicles."

kir Pr.-

However, the final product might not be available for general sale for another 18 months because tough Swedish safety standards demand rigorous and extended testing and VBG declines to predict its retail price.

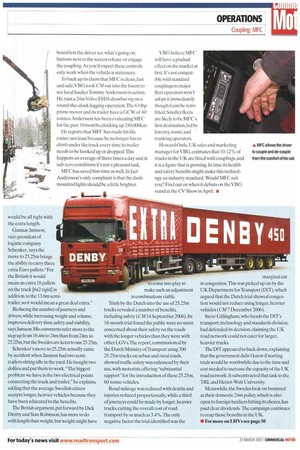

Five sensors Ml-C comprises a male/ female coupling that slots into place using five sensors four mounted on the truck and one on the couplingwith two sets of locking pins.

Once in place air hoses connect to the coupling with an electrical interface replacing external suzies. Articulation is handled by a universal joint with a hollow 114mm ball engaging with two cups.

A monitor on the dash board lets the driver see what's going on; buttons next to the screen release or engage the coupling. As you'd expect these controls only work when the vehicle is stationary.

To back up its claim that MFC is clean, fast and safe,VBG took CM out into the forest to see local haulier Tommy Andersson in action. He runs a 24m Volvo FH16 drawbar rig on a round-the-clock logging operation.The 610hp prime mover and its trailer have a GCW of 60 tonnes.Andersson has been evaluating MFC for the past 10 months, clocking up 240,000km.

He reports that MFC has made his life easier: not least because he no longer has to climb under the truck every time its trailer needs to be hooked up or dropped.This happens an average of three times a day and in sub-zero conditions it's not a pleasant task.

MFC has saved him time as well. In fact Andersson's only complaint is that the dashmounted lights should be a little brighter. VBG believe MFC will have a gradual effect on the market at first. It's not compatible with standard couplings so major fleet operators won't adopt it immediately though it can he retro fitted. Smaller fleets are likely to be 1VIFC's first destination, led by forestry, waste, and trunking operators.

Howard Ostle, UK sales and marketing manager for VBG, estimates that 10-12% of trucks in the UK are fitted with couplings, and it is a figure that is growing. In time its health and safety benefits might make this technology an industry standard. Would MFC suit you? Find out on when it debuts on the VBG stand at the CV Show in April. •