Good breathing aids 'no smoking' on

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

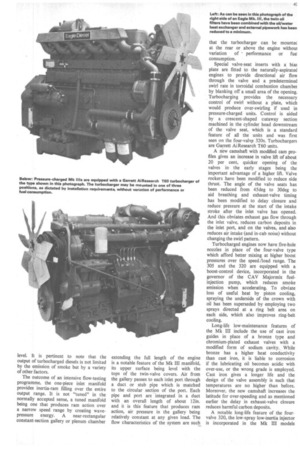

11P9R Eagle Mk III by Paul Brockington ROLLS-ROYCE announced a Mark III range of its Eagle diesels on Tuesday. Improved induction and combustion allied to long-life features have, it is claimed, enabledengines to be produced with the same ratings as the Mk II series but offering a substantial increase in smoke-level margins; a greater service tolerance in terms of miles run; performance that is less sensitive to inadequate maintenance or to misuse; and a more favourable fuel consumption.

In the development of the Eagle Mk III range of 205, 220, 265, 305 and 320 diesels, Rolls-Royce technicians set out to achieve optimum volumetric efficiency. They did this by employing an inlet manifold designed to give inertiaram filling, together with inlet-valve and combustion chamber features that promote the best use of the extra air.

All the engines are equipped with two-valve heads and have the same peak output ratings as the Mk II two-valve models from which they were derived, with the exception of the Eagle Mk III turbocharged 320. This is an uprated 305, whereas the Eagle 320 and 340 models introduced last year (CM Sept 22) have four-valve heads. While these units are not included in the Mk III range, they are available for special applications and a number of features that were "new" in the four-valve models are incorporated in the range.

An improvement in volumetric efficiency of 10 per cent has been obtained in the case of the Mk III turbocharged 265, 280, 305 and 320 models, the increase in efficiency of the 205 and 220 naturally-aspirated units being about 5 per cent; a gain of 4 per cent is attributable to inertia ramming in every case. While the compression ratio of the turbocharged engines is 14 to 1, the naturally-aspirated units operate on a 16 to 1 ratio.

As an example of the improvement in smoke control provided by the modifications, the level of a Mk III 220 in good condition is 20 Hartridge smoke units below the BS AU 141a limit throughout the operating range and this is well under the level of about 30 Hartridge units at which smoke is normally just visible to the naked eye. At the upper end of the range the 320 version is said to approach the visible level only when it is "lugged down" to well below its peak torque speed on full load. Minimum specific fuel consumptions of the turbocharged and naturally-aspirated engines are 0.3451b bhp /hr and 0.3631b bhp /hr respectively. In line with normal R-R practice peak outputs are obtained at 2100 rpm. Torque ratings are unchanged, the maximum torque of the Mk III 320 being 880 ft.lb. at 1500 rpm.

It is emphasized by Rolls-Royce that the better filling and combustion characteristics of the naturally-aspirated engines could be exploited to obtain higher maximum outputs, the potential of the 220 being a gain of at least 20 bhp without exceeding the BS AU 141a smoke level. It is pertinent to note that the output of turbocharged diesels is not limited by the emission of smoke but by a variety of other factors.

The outcome of an intensive flow-testing programme, the one-piece inlet manifold provides inertia-ram filling over the entire output range. It is not "tuned" in the normally accepted sense, a tuned manifold being one that produces ram action over a narrow speed range by creating wavepressure energy. A near-rectangular constant-section gallery or plenum chamber extending the full length of the engine is a notable feature of the Mk III manifold, its upper surface being level with the tops of the twin-valve covers. Air from the gallery passes to each inlet port through a duct or stub pipe which is matched to the circular section of the port. Each pipe and port are integrated in a duct with an overall length of about 12 in. and it is this feature that produces ram action, air pressure in the gallery being relatively constant at any given load. The flow characteristics of the system are such that the turbocharger can be mountec at the rear or above the engine without variation of ' performance or fuel consumption.

Special valve-seat inserts with a bias plate are fitted to the naturally-aspirated engines to provide directional air flow through the valve and a predetermined swirl rate in torroidal combustion chamber by blanking off a small area of the opening. Turbocharging provides the necessary control of swirl without a plate, which would produce over-swirling if used in pressure-charged units. Control is aided by a crescent-shaped cutaway section machined in the cylinder head downstream of the valve seat, which is a standard feature of all the units and was first seen on the four-valve 320s. Turbochargers are Garrett Ai Research T60 units.

A new camshaft with modified cam profiles gives an increase in valve lift of about 20 per cent, quicker opening of the valves in the early stages being the important advantage of a higher lift. Valve rockers have been modified to reduce side thrust. The angle of the valve seats has been reduced from 45deg to 30deg to aid breathing and exhaust-valve timing has been modified to delay closure and reduce pressure at the start of the intake stroke after the inlet valve has opened. And this obviates exhaust gas flow through the inlet valve, reduces carbon deposits in the inlet port, and on the valves, and also reduces air intake (and in-cab noise) without changing the swirl pattern.

Turbocharged engines now have five-hole nozzles in place of the four-valve type which afford better mixing at higher boost pressures over the speed/load range. The 305 and the 320 are equipped with a boost-control device, incorporated in the governor of the CAV Majormix fuelinjection pump, which reduces smoke emission when accelerating. To obviate loss of useful heat by piston cooling, spraying the underside of the crown with oil has been superseded by employing two sprays directed at a ring belt area on each side, which also improves ring-belt cooling.

Long-life low-maintenance features of the Mk III include the use of cast iron guides in place of a bronze type and chromium-plated exhaust valves with a modified form of sodium cavity. While bronze has a higher heat conductivity than cast iron, it is liable to corrosion if the lubricating oil becomes acidic with over-use, or the wrong grade is employed. Cast iron gives a longer life and the design of the valve assembly is such that temperatures are no higher than before. Moreover, the new camshaft increases the latitude for over-speeding and as mentioned earlier the delay in exhaust-valve closure reduces harmful carbon deposits.

A notable long-life feature of the fourvalve 320, the low-spray low-inertia injector is incorporated in the Mk III models nd other features that have been adopted Dr the new range include a spin-on hrow-away type of fuel filter, combined iounting of the oil filter and oil cooler ystems and a ceramic-faced water-pump eal. A system of baffles behind the push-rod over deflects oil from the area of the rutlet which eliminates the need for a titer in the breather, which is liable to get clogged.

The low-spring injector has a long-life by virtue of the reduced length of the needle push rod and the low inertia of the moving parts which is said to eliminate needle bounce, improve smoke control and to reduce wear. And because the injectors are mounted on the side of the block, any fuel that might leak from them would not contaminate the lubricating oil.

The spin-on fuel filter is employed in place of twin-filters with removable elements and mounting the two vertical oil filters with the oil-water heat exchanger (on the right side at the front of the crankcase) has enabled external pipes to be eliminated. In fact, nearly all oil and water connections take the form of internal galleries, which gives a notable improvement in the appearance of the engines. A modified water-pump housing is designed to give substantial support for a powersteering pump.

Speaking at a press conference on Tuesday, Mr Ron Whiteside, director of engineering of Rolls-Royce Diesel Division, forecast that it would be possible to reduce noise levels by 50 per cent in due course. This, he said, would be achieved by internal changes and shielding and by the use of appropriate materials.