Getting the Best from

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

A "Self-starting" Carburetter

By the

—7 Solex Service Manager

Lack of Knowledge of the Correct Use of This Instrument Can Result in Considerable Petrol Wastage

ENGINEERS responsible for the maintenance of fleets equipped with Solex '' Self starting" carburetters, in the main are acquainted with the difference in function between this type of cold-starting device and the old form of strangler. In a number of cases, however, the self-starting device is not completely understood.

The " starter " unit is operated either by a manual control, or by a thermostat on the exhaust manifold.

Lack of knowledge of the way in which it must be controlled in its manual form, or of the method of maintaining the thermostatic type can result only in petrol wastage or other evils, whereas a proper comprehension of its value and how to maintain it can account for marked economy in fuel and reduction in upkeep costs.

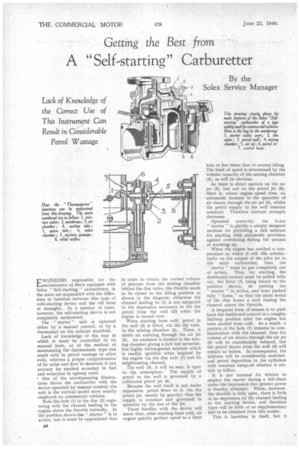

• One of the accompanying illustrations shows the carburetter with the device operated by manual control; the unit is the vertical model most usually employed on commercial vehicles.

Note the hole (1) in the disc (2) registering with the channel leading to the engine above the throttle butterfly. In the position shown -the." starter is in action, but it must be appreciated that

in order to obtain the correct volume of mixture from the mixing chamber behind the disc valve, the throttle needs to be closed to the idling position as shown in the diagram; • otherwise the channel leading to (I) is not subjected to the depression necessary to lift the petrol from the well (3) when the engine is turned over.

When starting from cold, petrol in the well (9) is lifted, via the dip tube, to the mixing chamber (4). There, it meets air entering through the air jet (5). An emulsion is formed in the mixing chamber giving a rich but nevertheless highly disintegrated mixture which is readily ignitible when inspired by the engine via the disc hole (1) and its neighbouring channel.

The well (3), it will be seen, is open to the atmosphere. The supply of petrol to the well is governed by a calibrated petrol jet (6).

Because the well itself is not under depression, petrol flows to it, via the petrol jet, merely by gravity; thus the supply is constant and governed in quantity by the size of the jet. Those familiar with the device will know that, after starting from cold, an engine quickly gathers speed to a limit

four or five times that of normal idling. The limit of speed is determined by the volume capacity of the mixing chamber (4), as will be obvious.

As there is direct suction on the air jet (5), but not on the petrol jet (6), there is, where engine speed rises, an automatic increase in the quantity of air drawn through the air jet (5), whilst the petrol supply to the well remains constant. Therefore mixture strength decreases.

Operated correctly, the Solex "

starter" is plainly a simply designed medium for providing a rich mixture for starting with automatic provision against overdosing during the process of warming up.

When the engine has reached a temperature at which it will idle satisfactorily on the output of the pilot jet in the main carburetter, then the " starter " must be put completely out of action. Thus, for starting, the dashboard control must be pulled fully out, the lever (7) being drawn to the position shown, so putting the starter" in action, and later pushed fully " home," so that the plain metal of the disc forms a wall closing the channel above the throttle.

A frequent form of misuse is to push back the dashboard control to a roughly halfway position after the engine has been started from cold. As a result, a portion of the hole (1) remains in communication with the channel; thus the volume of air drawn through the air jet (5) will be considerably reduced, but the petrol drawn from the well (3) will remain as before. In consequence, the mixture will be considerably enriched, and petrol deposition in the cylinders with eventual sump-oil dilution is certain to follow.

It is not unusual for drivers to employ the starter during a hill-climb under the impression that greater power is thereby obtained. When, however, the throttle is fully open, there is little or no depression on the channel leading to the starting device, and therefore there will be little or no supplementary fuel to be obtained from this source.

This is harmless in itself, but it creates a risk that the driver, on the hill descent, will omit to push home the dashboard control and trouble then begins. He may drive for long distances with the throttle only partly open. In such case, depression occurs on the " starter" and surplus fuel is used with ensuing heavy petrol consumption and eventual harmful effect on the engine.

• A practical method of dealing with these forms of abuse is to mount the control on the dumb iron or at some point out of reach from the driver's seat. It can then be operated to start the engine from cold, and put out of use so soon as the unit is warm enough for the vehicle to be driven away without its aid.

The best plan, however, to ensure that good results are obtained from the Solex " Self-Starting" carburetter is to employ the Thermostarter model, in which a thermostat controls the action of the " starter." E'en so, the maximum benefit cannot be obtained if its function be not clearly understood.

This device is shown in the other illustration. The action of the starter is controlled by the movement of valve 1, which is operated via its stem by the membrane (2). This membrane is, in effect, the expanding wall of a chamber (3) to which is transmitted the suction of the engine, through tube 4 and which is also connected to -the thermostarter box by the union tube (5). When the engine is started, either by hand or by the electric motor, the vacuum created in chamber 6 via tube 7 causes the valve (1) to open. Chamber 6 is then subjected to the engine suction and the starter works normally.

At the same time, chamber 3 is similarly put into depression by the suction of the engine through tube 4; this action, however, is very weak owing to the excess leakage through the relief orifice (8) via which the air enters.

As soon as the engine is warm, this orifice (8) is shut by the bi-metal strip valve, the vacuum in chamber 3 becomes equal to that in chamber 6. and, as the surface of membrane 2 is greater than that of the valve (1) , the suction on the former is the stronger and the valve shuts.

In this way the starter is put out of action; and before it can operate again the temperature must have dropped sufficiently to allow the bi-metal strip to straighten and uncover the orifice. In other words, the " starter" will remain inoperative until the engine cools down.

The device is perfectly simple, but certain points in maintenance must be observed. The membrane is composed of fibrous material which, after long usage, will deteriorate and probably puncture. In such case, the depression in the vacuum chamber (3) will be insufficient to suck the membrane back and so seat the valve (1). Thus there will be some leakage from the " starter" all the time the engine is running Regular inspection is therefore necessary, and it is recommended that the membrane be renewed every 10,000 miles. Its cost is only a few pence and prevention of trouble is always better than cure.

A little attention is also required by the connecting pipe between the " starter " and the thermostat. Vibration may cause the connection to loosen. At once air will leak inwards to chamber 3 and the result will be the same as if the membrane were punctured, i.e., the valve will not find its proper seating.

The bi-metal blade must work freely. Accidental damage to the metal box containing it, or an original bad centralization on the manifold studs may result in warping causing the blade to stick. If it sticks in an open position, the " starter " valve cannot close. The discovery will eventually be made that petrol consumption is excessive. Also the engine will race instead of idling correctly on a closed throttle. The wastage of fuel and damage to the engine may be considerable.

On the other hand, if the blade sticks in the closed position, it will be impossible to start the engine when cold.

A proper appreciation of the vital points of maintenance will enable the operator to obtain the utmost benefit from both types of Solex. Readers are cordially invited to communicate with • the writer of this article if any further information be required.