KNOW

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

by Les Ofdridge, T Eng(CEI), MIMI, AM IRTE

MoT tests: new points to watch

SCHEDULE 3 of the Motor Vehicle (Tests) Regulations 1976 describes how the examination of the various parts of a motor vehicle undergoing its MoT test is to be conducted.

I dealt with Part II (concerned with brakes) in my previous article. Steering, lights, tyres and brakes were examinable under the previous regulations, but to these are now added stop lamps, seat belts, direction indicators, road wheels, windscreen wipers and washers, exhausts, horns, bodywork and suspension.

Stop lamps are dealt with in Part V of the Schedule which requires the vehicle to be examined to ascertain whether: • It is equipped with stop lamps that comply with the stop lamp requirements as respects their number and the position in which they are attached to the vehicle;

D These lamps are in a clean 3 n d efficient condition;

• The vehicle is so equipped that these lamps show a steady red light when the brakes which operate the lamps are applied, and, where more than one lamp is fitted, that the light emitted by at least two of the lamps is emitted at the same time.

Part VII concerns seat belts and, whereas previously only the presence of seat belts was a statutory requirement, they must now be examined to see that they are in good and efficient condition, securely attached and that all load-bearing members of the vehicle structure within 30cm (11.8in or almost lft) of the anchorage points of the seat belts are in sound condition.

Part VIII of Schedule 3 requires that direction indicators be examined to ascertain that they are in a clean and efficient condition, of the right colour, visible from a reasonable distance, of the correct flashing rate and that the indicator warning lamps, in view from the driver's seat, are operative. Windscreen wipers and washers must be examined to ensure that they are in good and efficient condition so that the driver has an adequate view in front of the vehicle and to the front of the near and offsides (Part IX).

The vehicle must be examined to ensure an efficient exhaust system and horn are fitted (Part X and XI).

Rust Vehicle examiners have always had a problem in deciding if rust in bodywork is bad enough to warrant the vehicle failing its test. Part XII of Schedule 3 requires the vehicle to be examined -to ascertain whether the bodywork and suspension is so affected by rust, or has otherwise been so damaged, that the proper functioning of the braking system or steering gear is likely to be prejudicially affected by reason thereof."

The examination must be visual, particularly of the under

side, but it must not entail any dismantling of the vehicle or of any part of it.

The MoT tester's manual, Vehicle Testing, HMSO price £2, is extremely useful to mechanics preparing vehicles for the tests and to examiners who conduct them. It should help them to decide whether defects in a vehicle are sufficiently serious to warrant it failing the test. The book takes every item examined in the test and gives the method of inspection, the principal reasons for failure and general notes for the guidance of those concerned.

For example, the instructions for examining the parking brake reads: "Apply the parking brake and check that it can be set in the 'applied' position. Determine the effectiveness of the holding on mechanism by tapping the brake lever sideways and seeing the lever does not release; move the lever sideways to check for wear in the pivot bearing."

Among the reasons for failing a vehicle because of a defective parking brake are -with reasonable force applied to the lever, it cannot be set in the 'hold-on' position; the holding-on mechanism operates, but this is so • worn, or the sideways movement of the lever is such that the parking brake is likely to release inadvertently with small sideways force or accidental contact with the 'hold-on' mechanism.

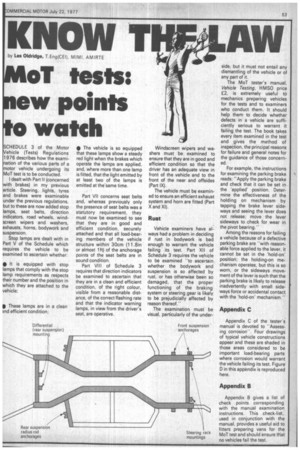

Appendix C Appendix C of the tester's manual is devoted to -Assessing corrosion". Four drawings of typical vehicle constructions appear and these are shaded in those areas considered to be important load-bearing parts where corrosion would warrant the vehicle failing its test. Figure D in this appendix is reproduced here.

Appendix B

Appendix B gives a list of check points corresponding with the manual examination instructions. This check-list, used in conjunction with the manual, provides a useful aid to fitters preparing vans for the MoT test and should ensure that no vehicles fail the test.