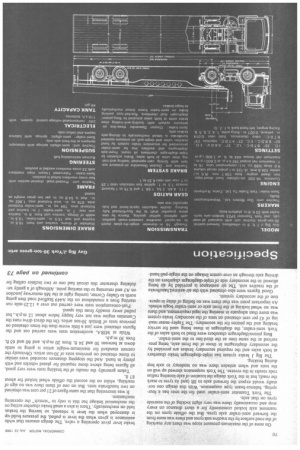

GUY BIG J/YORN )-TON-GROSS ARTIC

Page 70

Page 71

Page 72

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

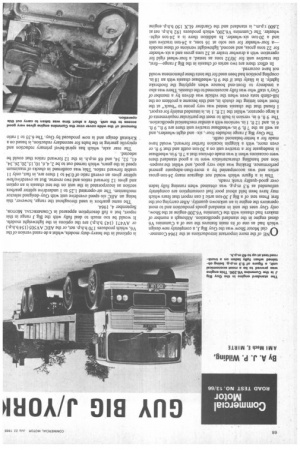

ONE of the more important introductions at the 1964 Commercial Motor Show was the Guy Big J, a completely new design which had as one of its main features the use of a Cummins V6 diesel engine in the standard specification. Although a number of makers had chassis with the Cummins V6.200 engine at the Show, only Guy uses the unit in standard goods production and to most operators the engine is an unknown quantity. After carrying out the first Press test of a Big J 30-ton artic I can report that fears which may have been held about poor fuel consumption are completely unfounded as 9.3 m.p.g. was obtained when running fully laden over good-quality trunk roads.

This is a figure which would not disgrace many 24-ton-gross artics and was accompanied by a more-than-adequate general performance. Braking was also very good, and whilst the suspenSion and handling characteristics were to a good standard there were occasions when it was made obvious that a 7 ft. 9 in. wheelbase is inadequate for a tractive unit on a 30-ton outfit and that 9 ft. or even more, with a kingpin location further forward, would have made for a better-balanced outfit.

The Guy Big J range includes four-, sixand eight-wheelers, and as well as the 7 ft. 9 in.-wheelbase tractive unit there are 9 ft., 9 ft. 6 in. and 12 ft. 1 in. versions with a similar mechanical specification. The 9 ft. 6 in. version is built to meet the particular requirements of a large operator, whilst the 12 ft. 1 in. is intended mainly for export. I found that the chassis tested was very prone to "buck" at the front when letting the clutch in, and this became a problem on the hill-climb tests even when the vehicle was driven by a member of Guy's staff who was fully accustomed to the chassis. There was also a tendency to front-end bounce when applying the footbrake lightly. It is likely that if the 9 ft.-wheelbase chassis with an 18 in. coupling position had been used for the tests these phenomena would not have occurred.

In effect there are two series of chassis in the Big J range—first, the tractive unit for 30/32 tons as tested, a four-wheel rigid for operation with a drawbar trailer at 32 tons gross and a six-wheeler for 22 tons gross, and second, lightweight versions of these models —a four-wheeler for use solo at 16 tons, a 24-ton tractive unit and a 20-ton six-wheeler. In addition there is a 24-ton eightwheeler. The Cummins V6.200, which produces 192 b.h.p. net at 2,600 r.p.m., is standard and the Gardner 6LX 150 b.h.p. engine is optional in the heavy-duty models, whilst a de-rated version of the V6, which produces 170 b.h.p. net, or the AEC AV505 (154 b.h.p.) or AV471 (143 b.h.p.) are the options in the lightweight models. It would be too much to deal fully with the Big J range in this report, but a full description appeared in COMMERCIAL MOTOR, September 4, 1964.

The same gearbox is used throughout the range, however, this being an AEC six-speed overdrive unit with Guy-designed selector mechanism. The air-operated 1.25 to 1 underdrive splitter gearbox section as incorporated in the unit on the test chassis is an option and gives 12 forward ratios and two reverse. But as overdrive/low splitter gives an overall ratio of 0.94 to 1 there are, in fact, only 11 usable forward ratios. This was confirmed in checks of maximum speed in the gears, which turned out to be 2, 4, 6, 10, 15, 20, 26, 34, 41, 52, 54, and 68 m.p.h. in the 12 forward ratios that could be selected.

The rear axle, which has spiral-bevel primary reduction and epicyclic gearing in the hubs for secondary reduction, is based on a Kirkstall design and is now produced by Guy. The 6.35 to 1 ratio n the test chassis is recommended for use in conjunction with ,articular engine and transmission specification. This turned out )e a good ratio for general operation in the area around verhampton where the tests took place, and the gearbox ratios lable were entirely satisfactory. The gear-change action was and the ratio change in the splitter section was positive, but engine took a little time to die down when making upward iges in the main gearbox.

was evident right from the beginning that a different technique iormal had to be used to get the best out of the Cummins ne, and here the extra fitting of an engine tachometer was a it benefit. Keeping the engine running at around 2,000 r.p.m. iuced the best performance and from my experience and that of Tious testing by Guy, optimum fuel consumption.

/sing the splitter box was of benefit only on hills so that when on tively flat roads only the ratios in the main box were changed, if the engine was run up to its maximum speed on one gear meant dropping into the next higher ratio at an engine speed ibout 1,400 r.p.m. As can be seen this is quite different to the normal, where in some cases the move to the high ratio is made with the engine running at little more than idling speed.

On all the laden tests the Big J and York semi-trailer outfit was running at just over its designed gross weights. The load consisted of 1-ton concrete blocks spaced fairly evenly over the 33 ft. 6 in. semi-trailer platform. This gave good axle distribution with the driving axle of the tractive unit 0.75 cwt. on the right side of the 10-ton legal limit.

Brake tests were the first to be carried out and because of the difficulty of finding a suitable road around Wolverhampton, the Motor Industry Research Association test ground at Nuneaton was used for these. The figures obtained were very good for an outfit grossing 30 tons, and the stopping distances obtained represent actual efficiencies of 42.5 -per cent from 20 m.p.h. and 49 per cent from 30 m.p.h. Comparing these with Tapley meter readings of 67 per cent from both speeds showed that there was little delay in the Guy braking system. On none of the maximum-pressure stops was there any marking of the road surface by the tractive unit tyres and there was none from the forward semi-trailer axle tyres. But the offside tyres on the rearmost axle locked consistently for a short distance on every stop and occasionally there was very slight locking of the nearside tyres on that axle.

The York Teamster semi-trailer used for the tests has a fourspring, balance-beam type suspension. With this design one normally would expect the forward axle to lift (and its tyres to mark the road), but in the York design the location of axle-locating radius rods results in the reverse. The York suspension showed up well on the tests and when unladen there was no tendency to axle hop during braking.

The Big J brake system has triple-diaphragm brake chambers at both axles and the required secondary brakes are provided by the secondary diaphragms in those of the front axle, being pressurized at the same time as the third-line to the semi-trailer.

Berg piston/diaphragm chambers were fitted to both axles of the York semi-trailer, the diaphragm in these being used for service braking and the pistons for the secondary. The Tapley-meter reading of 43 per cent obtained on tests of the secondary brake system was more than adequate in meeting the legal requirement, and there was no wheel locking at the front axle or semi-trailer bogie wheels. An important point was that there was no feeling of delay in operation of the secondary system.

Good figures were also obtained with the air-assisted, handbrake of the tractive unit. The air assistance is provided by air being allowed to the secondary side of triple-diaphragm chambers on the driving axle through an over-centre linkage on the single-pull hand brake lever pivot operating a valve. The design ensures that while assistance is given when the lever is pulled, the pressure build-up is destroyed when the lever is released, so leaving the brakes held on mechanically. There is also a small brake chamber acting on the mechanical linkage but this is only to "stretch" the operating mechanism.

It was interesting that the same figure of 21 per cent was obtained on two handbrake tests. But on one of them there was no sign of marking, whilst on the second the offside wheel locked for about 87 ft.

Taken generally the results of the braking tests were very good, all figures being above those required for plated vehicles and with plenty in hand. And the stopping distances recorded were similar to those obtained on previous tests of 30-ton artics. Obviously the current standard for maximum-weight artics is going to settle down at between 30 and 34 ft. from 20 m.p.h. and 60 and 65 ft. from 30 m.p.h.

While at MIRA, acceleration tests were carried out and the figures obtained were just a little worse than the times obtained on previous tests of British 30-ton artics. On the direct-drive runs the Cummins engine was not very happy below about 12 m.p.h., but pulled away steadily from this speed.

Fuel-consumption tests were carried out over a 12.25-mile run starting from a roundabout on the A449 Stafford road then going north to Galley Corner, turning right at the M6 motorway junction on A5 and returning to the starting point. Although of a gently undulating character this circuit had one or two inclines calling for !ward gear changes; the three roundabouts also involved ging to lower ratios in the gearbox. The figures of 9.3 m.p.g. and 15.6 m.p.g. empty were remarkably good for a 30-ton and compare with 11.2 m.p.g. and 14.5 m.p.g. for similar obtained with a Gardner 6LX-engined, Guy/York 24-tonattic tested by COMMERCIAL MOTOR in 1964.

is rather interesting that the productivity factors-gross ton;. and time-load-mileage factor-were almost identical for two machines. Further evidence of the advantageous fuel )my of the test vehicle is given when it is considered that ous 30-tonners tested have given between 6.1 and 7.2 m.p.g. unk road tests and previously-tested 24-ton outfits have given een 8.5 and 10.1 m.p.g.

llowing the laden fuel-consumption tests the outfit was taken ermitage Hill, which is on the Wolverhampton side of Bridg1, for gradient-performance tests. This hill has an average ent of 1 in 12, is 0.75 mile long and the maximum slope is 7.5.

cause we arrived at the top of the hill it was decided to do fadeance checks first and the outfit was drive,n down with direct engaged and the footbrake applied to restrict the speed to i.p.h. A full-pressure stop from this speed at the bottom after a asting 1 min. 35 sec. produced a Tapley-meter reading of 58 per just about 0.1 g. less than the maximum obtained on the cold tests. This result was very satisfactory and shows that the ;n should not suffer from fade problems.

lite attempts had to be made to complete a maximum-power nt of Hermitage because on the first two occasions it was .ssible to pull away after a change to bottom gear on the est section due to considerable "bucking" of the tractive unit.

.hird attempt was made from a rolling start (less than 2 m.p.h.) we managed to complete the climb without having to change bottom.

le total time taken was 4 min. 2 sec., with second/low engaged min, 19 sec., and the steepest section was only just surmounted is gear with the road speed down to about 2 m.p.h. and the ie slogging at about 1,000 r.p.m.

le reason for the "bucking" was, in my opinion, because of the wheelbase of the tractive unit and the 12 in. coupling position injunction with a "sharp" clutch action. It took a little time to ; perfect starts from rest with the outfit on the flat, but Harold of Guy Motors, who accompanied me on the test, got the omenon only on the hill climb test.

op-and-restart and handbrake-holding tests were carried out Lock Hill on the outskirts of Wolverhampton, where there maximum gradient of 1 in 5. Both facing up and facing

the slope the tractive unit handbrake held the outfit with ratchet engaged and the lever released-in other words, )ut air-pressure assistance. Easy restarts were made up the slope in both positions-in first low facing up and reverse low when facing down-without any of the "bucking" previously referred to.

From a driving point of view the Big J is a very good machine. The cab is very roomy and although in the unladen condition the first step is 2 ft. 4 in. from the ground and the floor 3 ft. 7 in., access to the cab is easy and helped by well-placed handrails. The interior of the Big J cab is finished to a high standard, being fully lined, and there is a thick rubber floor covering. Insulation against noise from the engine was found to be excellent and even when driving at maximum engine speed normal conversation was possible.

A centrally located instrument panel contains the speedometer and temperature, oil, air and charging current gauges and there are useful cubby boxes on both the driver's and passenger's side. Two padded sun visors and an interior light are standard and there is a steel tray for papers and so on fitted on the engine cover. All-round visibility is good, but I found that the view through the offside mirror was obstructed by the pillar between the quarter light and door window. A longer mirror arm would be needed to place the mirror in a better position. The mirrors themselves were reasonably well placed to give a good view to the rear.

All controls were easy to operate and the general feel of the brakes was good, although the pedal was a little sensitive, this being the cause of front-end bounce when making light brake applications.

It is possible to tilt the Big J cab when the Cummins engine is fitted, but this is only intended for major work on the power unit and a fair amount of dismantling is involved. For anything except complete overhaul, adequate access is provided by removing a wide cover held down by nine set bolts. Removing the cover, which involves also taking out the seats, took up 6 min. 25 sec. whilst replacing it and all the items removed from the cab to do the job took 7 min. 38 sec. Access to the dipstick and oil filler is through a small trap in the cover and this took 15 sec. It took a further 15 sec. to check the oil level.