LUBRICATING UNIVERSAL JOINTS.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published Patent Specifications.

Lubrication of universal joints has 'always been a difficult problem, chiefly Ml amount of the fact that the means arovided necessitated the owner or driver , either taking up half the floorboards of his car or lying on his back beneath it. Automatic methods of , attaining this end have been tried from time to time without much success, and undoubtedly the popularity of the

flexible disc type of joint is largely due to this Particular failing of the ordinary type.

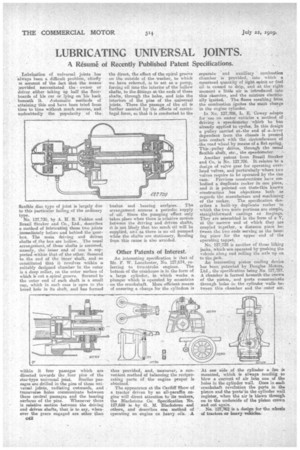

No. 127,720, by A. H. II. Fedden and Brazil Straker and Co., Ltd., describes a method of lubricating those two joints _immediately before and behind the gearbox. The main driving and driven shafts of the box are hollow. The usual arran.gement,of these shafts is assunied, namely, the inner end of one is supported within that of the other. Seemed to the end of the inner shaft, and so constituted that it revolves within a suitably designed chamber in the outer is a deep collar, on the outer surface of which is cut a spiral groove. Secured to the outer end of each shaft is a small cap, which in each case is open to the bored hole in its shaft, and has formed with'n it four passages which are directed towards the four pins of the

star-type universal joint. Similar passages are drilled in the pins of these universal joints, -radiating outwards, and tramsvease holes communicate between these central passages and the bearing surfaces of the pins. Whenever there is relative motion between the driving and driven shafts, that is to say, whenever the the gears engaged are other than

tatil the direct, the effect of the spiral groove on the outside of the washer, to which we have referred, is to act as a pump, forcing oil into the interior of the hollow shafts, to the fittings at the ends of these shafts, through the holes, and into the interiors of the pins of the universal joints. There the passage of the oil is further assisted by the effects of centrifugal force, so that it is conducted to the bashes and bearing surfaces, The arrangement ensures a periodic supply of oil. Since the pumping effect only takes plate when there is relative motion between the driving and, driven shafts, it is not likely that too much oil will be

d"

supplied, an as there is no oil pumped while the shafts are stationary, flooding from this cause is also avoided. _

Other Patents of Interest.

An interesting specification is that of Mr. F. W. Lanchester, No. 127,674, referring to two-stroke engines. The bottom of the crankcase is in the form of a, large cylinder, in which works a plunger which is 'operated by eccentrics on the crankshaft. More efficient means of ensuring a charge for the cylinders is thus provided, and, moreover, a convenient method of balancing the reciprocating parts of the engine proper is obtained.

The appearance at the Cardiff Show of a tractor driven by an all-paraffin engine will direct attention to' it. makers, the Blackstone Co: Specification No. 127,699 is by G. M. Blackstone and others, and describes one method of operating an engine on heavy oils. A

separate 'and auxiliary combustion chamber is provided, into which a measured quantity of light spirit 401' fuel oil, is. caused to drip, and at the right moment a little air is introduced into this chamber, and the mixture electrically ignited. The flame resulting from the combustion ignites the main charge in the engine eylinder.

In No. 127;709, L. E. Cowey adapta for use on motor vehicles a method of , driving a speedometer which he has already applied to cycles. In this design a pulley carried at. the end of a—lever dependent from the chassis is pressed into contact with the circumference of the road wheel by means of a flat spring. . This pulley drives, through the usual flexible shaft, etc., the speedometer.

Another patent from Brazil Straker and Co. is No. 127,726.• It relates toa design of valve gear for operating overhead valves,. and particularly where two valves require to be operated by the one cam.. Previous constructions have embodied a duplicate rocker in one piece, _ and it is pointed out that+ this known cOnstruction has objections both a,s regards the. manufacture and machining

of the rocker. The specification describes a built-up duplicate rocker in • which the two main portions are simple, straightforward castings or forgings. They are assembled in the form of a V, at the narrow end of which they are coupled together, a distance piece between the two ends serving as the bearing piece for the upper end of the operating tappet.

No. 127,739 is another of those lifting jacks, which are operated by pushing the vehicle along and rolling the axle up on to the jack. An interesting piston cooling device has been patented by Douglas Motors, Ltd., the specification being No. 127,767. A chamber is formed beneath the crown of the piston, and ports communicate through holes in the cylinder walls between this chamber and the outer air.

At one side of the cylinder a fan is mounted, which is always tending to blow a current of air into one of the holes in the cylinder wall. Once in -each crankshaft revolution the ports in the piston and the ports' in the cylinder wall register, when the air is blown through on to the underside of the piston crown and out again.

No. 127,762 is a design for the wheels of tractors or heavyvehicles.