TRACTORS FOR THE LINCOLN TRIALS.

Page 14

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

The Main Features of the AlIdays, Garner and Austin Models.

THE ALLDAYS, All-British, All-Purposes traetor has undergone one or two important changes during the last month or so. The water ballast tank, originally fitted so as to enable the load over the rear wheels to be graduated in accordance with, requirements, has been eliminated, it having been found to be hardly necessary, and, amongst the tractors already sold, seldom used.

The -engine has been considerably altered—practically redesigned. An increase of 5 h.p. at fewer revolutions per minute is one result, and the power unit itself presents an example of the most modern practice in engine design. In fact, it may be stated that the engine is the most interesting component of this model Mark II, as the new AlIdays tractor is designated. A monobloc casting embodies the four cylinders and the crankcase, including its five bearings. The casting is brought down considerably below the centre line of the crankshaft, and the bearings are substantially ribbed to the -deep walls of the casing thus formed. The cylinder heads are independent, being circular in form and sufficiently deep to allow of their use as valve cages. The joint between head and cylinder wall in each case is al circular one, the gasket being a plain copper-andasbestos ring. The upper joint, between the outer wall of the cylinder and the flange of the head, is made by a rubber ring embedding itself in a groove in in the head.

A point worthy of note is the unusual depth of water above the cylinder heads, and another feature in regard to the cooling is the effective circulation space round both exhaust and induction valves, ports and seats. These heads are held in place by dogs of special form. The valves are operated by overhead rockers, made of bronze, which bear on fixed steel. spindles. A cavity -Within the rocker allows of the provision of ample lubricant, and it is anticipated that the machine will Tun for many months without any need for replenishment here. Only three gears are needed for the valve gear, magneto and pump drives. A skew spiral pinion on the crankshaft engages with another on the camshaft and this again drives a third, which is set with its axis at right angles to the other two so that pump and magneto lie across the front of the engine. This arrangement considerably increases the accessibility of the magneto, and it should be further noted that the bracket for the latter is formed with a spigot which fits in a recess on the crankcase, so that there is no fear of the magneto being assembled in anything but correct alignment with the driving shaft.

e28

Another item of interest in the design of this -tractor is the flexible disc type of universal coupling which intervenes, between the clutch and gearbox. There are three spiders to this joint instead of, as is usual, only two. One is -secured to the male portion of the Ferodo-lined cone clutch, and, consequently, .moves to and fro,with that member as the clutch is engaged or disengaged. To this spider, at three points, the flexible discs are secured. in the customary manner.The ,second • spider is similar to the first, except that it does •not-itself drive any shaft but rests within the first-mentioned spider. The bolts, however, which secure it to the .discs have long cylindrical heads which bear in bushed holes in the third spider, which is securely fastened to the main driving shaft of the gearbox. Consequently, when, as a result of the operation of the clutch, the foremost spider slides, it carries with it the discs and the intermediate portion of the coupling. The third spider, however, does not move longitudinally, that being obviated by the bolt heads of number two spider sliding endwise. In this manner is unnecessary flexion of the discs. entirely

The gearbox is a substantial and well-built component. If anything ever does go wrong with this part of the tractor, it will certainly not be on account of lack of strength. The first reduction occurs in the pair of bevels, the pinion of which is secured to the main driving shaft of the box, which' is, of course, in line with the engine shaft. The other shafts are transverse: That nearer the front takes the drive from the bevel pinion, and has secured to it the necessary pinions and gears for the various reductions. It is prolonged through the wall of the box on the offside of the chassis, and, on the protruding end is mounted a chain-sprocket pinion. This drives forward through a roller chain to a cross shaft before the box, at the other end of which is fitted a belt-driving pulley 14 ins, diameter and 6 ins. wide. The driving chain is completely enclosed, and adequate provision is made for tensioning and lubricating, it.

The second shaft in the gearbox carries sliding gears by which three speeds forward and one reverse are provided. It extends through the offside of the box, there to support the foot-brake drum, and through the near side to accommodate twin sprockets for the double roller chain drive to the differential .gear on the rear axle. To the rear driving sprocket is secured a winding drum. One of -the sun wheels of the differential gear is coupled

to the axle only through the medium of a substantial jaw clutch. If this clutch be withdrawn the drive is then transmitted only to the winding drum, the purposes of which are manifold, and will occur

to our readers. A second brake operated by handWheel and screw operates a contracting 'band on a drum_ secured to the rear axle. The AlIdays tractor sells, .complete, for £595, and may certainly be expected to .give a very good aecount of itself at the Trials.

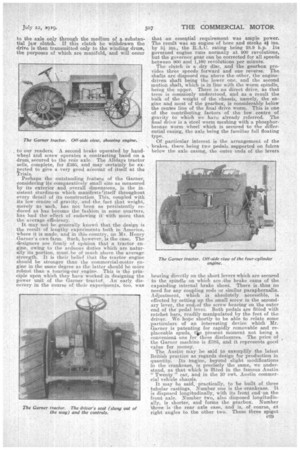

Perhaps the outstanding feature of the Garner, considering its comparatively small size as measured by its exterior and overall .dimensions, is the insistent gturdiness which manifests7itself throughout every detail of its construction. This, coupled with its low centre 'of gravity, andthe, fact that weight, merely as s,uch, has not been as perSistently reduced as has become the fashion in some quarters, has had the effect of endowing it with more than the average efficiency. • It may not he generally known that the design is the result of lengthy experiments both in America, where it is made, and in this country, on Mr. Henry Garner's own farm, Such, however, is the case. The designers are firmly' of opinion that 'a tractor engine, owing to the arduous duties which are naturally its portion, must_he of -much above the average strength. It is their belief that the tractOr engine should be stronger, than the commercial-motor engine in the same degree as the latter should be more robust than a touring-ear .engine. This is the principle upon which they have worked in 'designing the power unit of the (4arner tractor. An' early, discovery in the course of their experiments, too. was that an essential requirement was ample power. The result was an engine of bore and stroke 4* ins. by Nins., the R.A.U. rating being 28.9 h.p. Its governed engine runs normally at 900 revolutions, but the governor gear can be corrected for all speeds between sou and 1,100 revolutions per minute. The clutch is a dry disc, and -the gearbox provides three speeds forward and one reverse. The shafts are disposed one above the other, the enginedriven shaft beingthe lower one, and the second motion shaft, which -is in line with the worm spindle, being the upper. There is no direct drive, as that term is commonly understood, and as a result the bulk of the weight of the chassis, namely, the engine and most of the gearbox, is considerably. below the cerebre line of the final drive worm. This is one of the contributing. factors of the low centre of gravity to which we have already referred. The final drive is a steel NvOrm meshing with a phosphorbronze worm wheel which is secured to the differential casing, the axle being the familiar full floating type..

Of particular interest is the arrangement of the brake, there being two Pedals supported on fulcra below the axle casing, the outer ends of the levers

bearing directly on the short levers which are secured to the spindle on which are the brake cams of the expanding internal brake shoes. There is thus no need for any coupling rods or similar paraphernalia. Adjustment, which is absolutely accessible, is effected by setting up the small screw in the se‘condary lever, the enthof the screw bearing on the outer end of the pedal lever. Both pedals are fitted with ratchet bars, readily manipulated by the feet of the driver. We hope shortly to be able to relate some particulars of an interesting device which Mr. Garner is patenting for rapidly removable and -replaceable spuds, tie nresent moment not being a conVenient, one for these disclosures. The price of the Ga-rner machine is £385, ane,1 it represents geed value for money. The Austin may be said to exemplify the latest British practice as regards design for production in quantity. Its 'engine, beyond slight modifications in the crankcase, is precisely the same, we understand, as that which is filted in the famous Austin " Twenty " car, and in the 30 cwt. Austin commercial vehicle chassis.

It may be said, practically, to be built of three tubular cae-tings. Number one is the 'crankcase. It is disposed longitudinally, with its front end onthe front axle. Number two, also disposed longitudinally, is shorter, and forms the gearbox. Number 'three 'is the rear axle case, and is, of course, at right angles to the other two. These three spigot one into another so that their assembly and dissembly is work of the simplest nature. The arrangement, therefore, makes for accesaibility, besides providing a chassis of considerable natural strength.

The engine is of 3* ins, bore and 5 ins. stroke. All the four cylinders are cast together, another casting being the detachable head for the four. The wellknown Austin clutch, with pressed-steel male member, and Ferodo lining in segments, is contained within the second tubular casting which we have named, and it transmits the power from the engine to a longitudinal splined shaft, at the other end of which is a bevel pinion. The first reduction from the engine is through this bevel pinion and corresponding bevel gear, which is secured on splines on a transverse gearbox shaft. The familiar sliding, gears on this shaft provide for two further reductions which are alternative, giving thus two forward speeds, while a reverse gear is also fitted.

Particular interest, however, attaches to the design of the second motion shaft. This is of unusually large diameter, and, instead of splines, gear teeth are cut along its whole length. The centre portion serves as a pinion, and with it is engaged a large spurwheel of the rear axle ; the latter drives the differential gear in the usual way, the driving axles, however, ;being so arranged that they have to support the weight of the tractor and to transmit the effective drawbar pull as well as the driving

torque. The first and second speed wheels of the box are on this shaft. They are in the form of gear rings bolted to cast steel split bosses, which slide on to the teeth cut on the shaft and are clamped in position by bolts. By removing the clamping bolts, it is possible to withdraw this shaft through either , of two retaining covers which hold in place the Timken roller bearing in which the shaft is journaled. One end of the first motion shaft projects through a stuffing box and is key-wayed for the reception of the large diving pulley. A substantial brake drum with internal-expanding shoes is fitted to each rear wheel, and these brakes are independently operated—each by a hand lever working in a quadrant. In addition to acting as brakes, they may also be made to serve to assist in turning the tractor in a very short radius. Particularly interesting, however, is the design of the front axle, which is universally coupled at its centre to i bracket beneath the radiator, so that freedom of motion in almost any desired direction is obtained. This, tractor weighs only 26 cwt., notwithstanding which it is claimed that it can in favourable circumstances exert a drawbar pull of 3,000 lb. Withal, it sells complete for £300.