Standard Halv

Page 36

Page 37

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

le Foot-work By John F. Moon, A.M.I.R.T.E.

Standrive Two-pedal Control Gives Good Results when Tested on a 6-cwt. Van: Marked Economy on Delivery Work

iNCREASING attention is being paid. by British designers to the . reduction of driving effort of both cars and commercial vehicles, and in this respect the growing use of fully and semi-automatic transmission systems is important. Last September, the Standard Motor Co., Ltd., announced that they could offer a form of two-pedal control on their 10 h.p., cars and 6-cwt. commercial vehicles, and this transmission has shown on test to possess all the advantages its manufacturers claim for it.

The vehicle for test was a 6-cwt. van. Its rather simple appearance is deceptive, for it has a lively performance afforded by a high power-toweight ratio, with a gobd-sized and sensibly shaped payload compart ment. The addition of a two-pedal transmission makes it eminently suitable for local delivery work, in that all the irksome business of declutching is dispensed with.

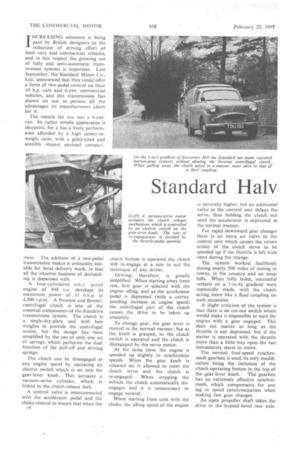

A four-cylindered o.h.v. petrol engine of 948 c.c. develops its maximtim power of 33 h.h.p. at 4,500 r.p.m. A Newton and Bennett centrifugal clutch is one of the essential components of the Standrive transmission *stem. The clutch is a single-dry-plate unit with bob weights to provide the centrifugal action, but the design has been simplified by the use of only one set of springs, which performs the dual function of the pull-off and driving springs.

The clutch can be disengaged at any engine speed by operating an electric switch which is set into the gear-lever knob. This actuates a vacuum-servo cylinder, which is linked to the clutch-release fork.

A control valve is interconnected with the accelerator pedal and the choke control to ensure that when the

(-8

clutch button is operated the clutch will re-engage at a rate to suit the technique of any driver.

Driving, therefore, is greatly simplified. When starting away from rest, first gear is selected with the engine idling, and as the accelerator pedal is depressed (with a corresponding increase in engine speed) the centrifugal part of the clutch causes the drive to be taken up smooth] y.

To change gear, the gear lever is moved in the normal manner, but as the knob is grasped, so the clutch switch is operated and the clutch is disengaged by the servo motor.

At the same time, the engine is speeded up slightly to synchronize speeds. When the gear knob is released air is allowed to enter the clutch servo and the clutch is re-engaged. When stopping the vehicle the clutch automatically disengages and it is unnecessary to engage neutral.

When starting from cold with the choke, the idling speed of the engine is naturally higher, but an additional valve in the control unit delays the servo, thus holding the clutch out until the accelerator is depressed in the normal manner.

For rapid downward gear changes there is an extra air valve in the control unit which causes the return action of the clutch servo to be speeded up if the throttle is left wide open during the change.

The system worked faultles.sly during nearly 500 miles of testing. in towns, in the country and on steep " hills. When fully laden, successful restarts on a 1-in-41 gradient were repeatedly made, with the clutch acting more like a fluid coupling on such occasions.

A slight criticism of the system is that there is no cut-out switch which would make it impossible to start the engine with a gear engaged. This does not matter as long as the throttle is not depressed, but if the starter is operated with the throttle more than a little way open the van immediately starts to move.

The normal four-speed synchromesh gearbox is used, its only mOdification being the inclusion of the clutch-operating button in the top of the gear-lever knob. The gearbox has an extremely effective synchromesh, which compensates for any lag in speed synchronization when making fast gear changes. _ An open propeller shaft takes the drive to the hypoid-bevel rear axle. Girling hydraulic brakes are used. The master cylinder is bolted to the front bulkhead and has a pendant operating pedal.

Although the braking area is relatively small for a van running at 1 tons gross, the brakes are effective, hut their full effectiveness is not apparent from the data panel on page 110, because the tests were made in heavy rain.

Independent front suspension, incorporating coil springs and Wishbones with telescopic dampers, is inherited from the private car, and the rear suspension consists of semi-elliptic springs with lever-type dampers.

Unit co-nstruction of body and chassis frame is employed in both the van and pick-up versions, and the bodywork is well finished, particular attention being paid to the elimination of rattles and draughts.

Large lights are. incorporated in the rear doors, with the result that rearward visibility is better than usual for British vans of this capacity, but the seating position is strangely low and forward visibility somewhat restricted. Two driving mirrors are provided—one on the off-side wing and one on the dash board—but the latter would give a better range of vision of it were to be mounted at the top of the windscreen.

The vehicle had covered nearly 1,500 miles before I received it and a payload of 6 cwt. of sandbags had beenprovided. With myself and passenger aboard the gross weight was 11 tons, of which 10 cwt. was carried by the front wheels.

To allow for the difference in inter-axle loading, the manufacturers recommend that the front tyres be inflated to 22 psi. and those at the rear to 26 p.s.i. I found these pressures somewhat low, however, and conducive towards oversteering. Greater stability is achieved with the rear tyres at 30 p.s.i.

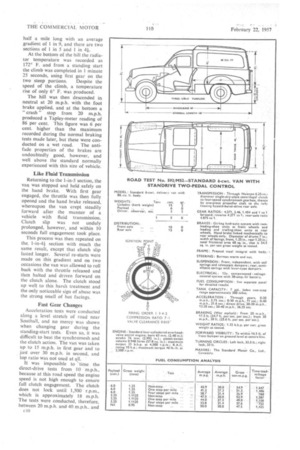

Fuel-consumption figures were obtained first, using a five-mile circuit between Sheldon and Meriden. This undulating threelane road was fairly clear of traffic during the tests and figures were taken in both directions of the course to ensure average results.

A graduated test tank was employed, and when making stops each was of 15 seconds' duration, during which time the engine was left idling.

The figures are good for a 6-cwt.

van, the " four-stops-per-mile" results being particularly satisfactory. When making the non-stop runs, a speed of 35 m.p.h. was maintained and the throttle was not spared for the sake of obtaining good figures.

Succombs Hill was the scene of the hill-climb and brake-fade tests. which were made in an ambient temperature of 45 F. This hill is half a mile long with an average gradient of 1 in 9, and there are two sections of 1 in 5 and 1 in 4+.

At the bottom of the hill the radiator temperature was recorded as 172° F, and from a standing start the climb was completed in 1 minute 25 seconds, using first gear on the two steep portions. Despite the speed of the climb, a temperature rise of only 6° F. was produced.

The hill was then descended in neutral at 20 m.p.h. with the foot brake applied, and at the bottom a " crash " stop from 20 m.p.h. produced a Tapley-meter reading of 86 per cent. This figure was 6 per cent. higher than the maximum recorded during the normal braking tests made later, but these were con

ducted on a wet road. The antifade properties of the brakes are undoubtedly good, however, and well above the standard normally experienced with this size of vehicle.

Like Fluid Transmission

Returning to the 1-in-5 section, the van was stopped and held safely on the hand brake. With first gear engaged, the throttle was then fully opened and the hand brake released, whereupon the van crept steadily forward after the manner of a vehicle with fluid transmission. Clutch slip was not unduly prolonged, however, and within 10 seconds full engagement took place.

This process was then repeated on the 1-in-4+ section with much the same result, except that clutch slip lasted longer. Several re-starts were made on this gradient and on two occasions the van was allowed to roll back with the throttle released and then halted and driven forward on the clutch alone. The clutch stood up well to this harsh treatment and the only noticeable sign of abuse was the strong smelt of hot facings.

Fast Gear Changes

Acceleration tests were conducted along a level stretch of road near Southall, and no mercy was shown when changing gear during the standing-start tests. Even so, it was difficult to beat the synchromesh and the clutch action. The van was taken up to 15 m.p.h. in first gear and to just over 30 m.p.h. in second, and iop ratio was not used at It was impossible to time the direct-drive tests from 10 m.p.h., because at this road speed the engine speed is not high enough to ensure full clutch engagement. The clutch does not lock until 1,500 r.p.m., which is approximately 18 m.p.h. The tests were conducted, therefore, between 20 m.p.h. and 40 m.p.h., and c I 0 te resulting figures show a satisfaciry top-gear performance.

Although the ignition was set to tit commercial-grade petrol, slight inking was apparent when making iese acceleration tests and on hills, rid the ignition could with advantge have been further retarded. he maker's setting was 3° after top cad centre.

I was unaccompanied during the raking tests and conditions were far rom ideal, because of heavy rain nd a slippery surface. Nevertheless, ie figures recorded were satisfacDry and skidding was not excesive, even when braking from 0 m.p.h.

On dry roads the stopping distance rom 30 m.p.h. should be well under 5 ft. The small facing area cerainly does not affect braking effiiency and will be apparent only in espect of reduced facing life. Handwake tests from 20 m.p.h. on a dry oad showed an average efficiency )f 44 per cent., which is excellent.

Meagre Tool Kit A complete tool kit is not supplied vith the van, so it was difficult to :onduct a full series of maintenance ests. Those tools that are supplied ire restricted to jack, starting handle, wheel brace, tyre levers, budget-lock cey and tyre-valve key.

Certain tasks were carried out, but .hose were restricted to the simple lobs which should be done fre.juently. The alligator-type bonnet is Inlocked by a control which is reached through the radiator-grille aperture, and the bonnet was lifted and prop applied in 6 seconds. Next I checked the water level (5 seconds) and the engine-oil level (15 seconds). The single 12v. battery is stowed above the near-side front wheel and it was possible to verify the electrolyte level in half a minute.

The brake master cylinder has a built-in reservoir, the level in which was verified in 7 seconds, no spanner being necessary to remove the cap.

The triangulated screw jack engages in sockets below the body sides, there being one adjacent to each wheel on each side. With the van loaded, however, it is necessary to jack up only at the rear point on either side to lift both wheels on that side clear of the ground.

All Brakes Adjusted I was thus able to jack up the nearside wheels in 21 minutes, and it took me a minute to adjust the front brakes and 20 seconds to adjust those at the rear. A further 1 minute 20 seconds was then required to lower the jack.

Almost the same time was needed for the adjustment of the off-side brakes. Using the jack provided it is possible to adjust all the brakes in II minutes so long as the correct spanners are to hand.

Combined filler and level plugs are incorporated in the gearbox and rear axle, and it is necessary to get underneath the vehicle to check the levels in both these units. The times taken were 40 seconds and 35 seconds respectively.

Semi automatic transmission makes the Standard .6-cwt, van a good proposition for all operators of light vehicles, particularly as the Standrive control is offered at only £16 I Is. 3d, extra cost (this figure includes £3 bs. 3d. purchase tax). Other than the rather low driving position the van is pleasant enough to handle, and at all normal speeds the engine is quiet.

The suspension is extremely well balanced and capable of cancelling out all excessive road roughness. With the rear tyres inflated to 30 p.s.i., the Veering is light and positive, and fast cornering is possible without causing undue rolling.

Instruments are rather sparse, being confined to a speedometer and mileage recorder, fuel-contents gauge and charging and oil-pressure warning lights. Flashing direction indicators are controlled from beneath the steering wheel, the switch incorporating a flashing repeater bulb.

Tubeless Tyres Standard

Tubeless tyres are standard equipment and a spare wheel is carried. This is stowed beneath the rear of the body and is reached by removing a detachable panel secured by twe budget locks.

The van has a basic price of £390, and in Great Britain a further £52 12s. 8d. is payable in purchase tax. The optional passenger seat, which was fitted to the test vehicle. costs £5 10s. when ordered as initial equipment. Other optional extras include heating and demisting equipment (£13), a wireless set (£22 10s.), tool kit, roof lamp and radiator stoneguard. The basic price of the pick-up truck is £385, and purchase tax is 152 19s. 2d.