The four-wheel drive replacement for mules

Page 20

Page 21

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

SEVERAL years before the outbreak of the First World War American Army engineers were seeking to replace horses and mules with a motor lorry which would run all day and go anywhere that the traditional four-mule team would go.

The list of famous companies which evolved around this time was seemingly endless. It included such illustrious names as Packard, White, the original Diamond T, Ford, Pierce-Arrow, Peerless and Kelly-Springfield, to mention but a few.

Many submitted their vehicles to the US Army for testing but, with over two million miles of unmade roads and tracks in the USA at that time, it was the all-wheel-drive motor lorries which made the greatest impression.

Four-wheel drive was not exactly new at that time. There had been cars and steam and electrically driven vehicles of that design built by the turn of the century.

For instance, a truck built in 1902 by the Electric Vehicle Company of Canton, Ohio, had electric motors on all four wheels, giving it not only all-wheel drive but also the first example of powered steering.

Foremost in the four-wheel-drive stakes was the FWD (Four Wheel Drive) Corporation of Clintonville, Wisconsin. It began in 1908 by adapting a White steamer and went on to build its own gasoline-engined models.

In those days of rapid development competition was always close at hand. At nearby Kenosha one of the most versatile and innovative vehicles of the period, the Jeffrey Quad, was in embryo.

Not only did it have four-wheel drive, but it also steered with all four wheels. More significantly for vehicles of that pioneering era, it had brakes on both axles too.

Production eventually began in 1913 at the Thomas B. Jeffrey plant. (Rambler bicycles and the original Rambler car were also produced here.) But in 1916 it was sold to Nash Motors, later to be absorbed by American Motors Corporation.

Between 1914 and 1916, several thousand Quads were produced, some for the home market, but most went to the Russian and French governments.

While Quads were -being deployed in the Great War, they were also being used by the American Army between March 1916 and February 1917 to carry General Pershing's troops into Mexico against the outlaw Pancho Villa. In April 1917, when the US finally declared war against the Axis, production was stepped up at Kenosha to supply the American Expeditionary Force. During that year the Quad carried both the Jeffrey and Nash names but from 1918 until production ceased in 1928, it was known as the Nash Quad.

Many of these vehicles were converted to ambulances and signal trucks but in the main they ferried food, ammunition and supplies across the war-torn French battlefields.

With the signing of the Armistice came the problem of the disposal of war-surplus machines. In America massive road-building schemes absorbed large numbers, but in Britain many of these vehicles were either sold to contractors, transport companies or simply scrapped. Much the same fate occurred to those stranded in mainland Europe and few remain today.

By chance, Richard Peskett, a restoration consultant from Hindhead, Surrey, and a man with a flair for rebuilding historic vehicles, heard of an old WWI Jeffrey Quad which had been seen in 1970 crumbling away in a field by the Le Mans 24-hour Race circuit.

Nine years later, -Richard successfully negotiated the purchase of the remains from the Automobile Club de rOust which owns the Le Mans circuit. It had acquired it as army surplus in 1919 and used it on the circuit as a maintenance vehicle up to 1952. After that it had been abandoned and vandalised, Now, four years later and after many hours of painstaking research and re-engineering by Richard, the 1915 Jeffrey Quad, serial number 70237, stands in a condition as near to its original as it can possibly be.

Thomas B. Jeffrey's two-ton Quad had a durable build, even by today's standards. Until mid-1915 Jeffrey had built and fitted his own 32.4hp four-cylinder gasoline (petrol) engine.

Richard's late-1915 4016B model had the four-cylinder HU engine made by Buda of Harvey, Illinois. It was of three-piece construction with separate sump, cast-iron crankcase and cylinder block.

With its 108x 133 mm (4.25x5.25mm) bore and stroke it produced 21.5kW (28.8hp). This, the company declared in an advert from The Commercial Motor of December 28, 1915, is sufficient to pull a five-ton trailer as well as its own two-ton laden weight, atspeeds between five and seven mph on an average British road. With gasoline costing around 1/3d (5p) per gallon its 2 to 3 mpg was not mentioned.

Lubrication was maintained by force-feed and splash. A sight-feed glass on the left-hand side of the block shows the driver that oil is well. To see it, though, he has to remove the engine cover.

A centrifugal pump circulated the coolant but one of the Quad's biggest failings was its large, honeycomb-cored radiator. Although it sat on spring-loaded mountings, the terrible road surfaces of the day and solid-tyre wheels caused excessive vibration followed by endless leaks.

Each radiator had 9,800 short brass tubes which were solderdipped front and rear, but neither manufacturing nor front-line repair processes were of a high standard. Indeed, a general report after the war showed that normal daily leakages per radiator of this type was 15 to 20 gallons.

An Eisemann G4 impulse magneto, which could be advanced or retarded by the lever on the steering wheel, provided the spark, while the petrollair mix was via the Stromberg M-type carburettor.

Buda used a Pierce-type mechanical governor operated by a flexible drive from the flywheel to control the mixture.

Drive was transmitted through the conventional Borg and Beck dry plate clutch which also had a clutch brake.

A propeller shaft fitted with leather couplings carried the drive to Jeffrey's own gearbox — a fourspeed constant mesh unit with a Whitney inverted drive chain to turn the gear shafts. Ratios were 6.10, 3.55, 2.02, 1.22 to 1; reverse being 6.46 to 1.

Output shafts fitted with cardantype universal joints drove into both axle differentials. These were known as the MS or Muehl units, after the German inventor, and look very similar in design and operation to the Gleason Torsen differential which appeared in CM, May 5, 1984.

Worm wheels are interposed between the sun wheel and planetary pinions (both with worm teeth), but their axis are at right angles to the pinions.

These angles are such that, while the sun wheels can drive the worms, the worms cannot drive the sun wheels. This action ensures that when road resistance is reduced, causing wheelspin, the differential is locked and drive is transmitted from the wheel that has the grip. If the Muehl device was nove for its time, then so was the way it was mounted on to the dead Ibeam axle and then shaft-driven through the brake drums to an annulus within each road wheel.

The wheels, too, were unusual for the day, being nickel-vanadium cast-steel discs which weighed 18kg (401b) less than the wooden equivalent.

Transmission parking brakes are not new, either, as the Quad used an external-contracting one on the transmission shaft which operated via compensating linkages with the four internal-expanding drum brakes.

Considering that conscripted muleteers were given the job of propelling these "horseless carriages" it is not surprising that many drivers knew little about the "infernal machines". Because of this, manufacturers with military contracts were required to forge the letters B and C on the relevant pedals.

Driving the Quad could be almost as whacky initially as driving mules, until you got used to the four-wheel steering. Pulling it on to a full right-hand lock turned the front to the right but, through the linkage, the rear wheels pivoted to the left.

On the American Indian trails or on the battlefields this was fine, but in narrow lanes or between barns, it could be devastating. The upright column and driving position required the arms of a charioteer too.

Jeffrey fitted a Lavine type of steering box which had an irreversible worm and split nut and the vehicle could just manage to turn in 16.9m (55ft) — not bad considering its 3.1m (124in) wheelbase and the tail-end swing.

The steel channelled frame was of a parallel, ladder-type construction with lengthy gussets at the rear to bear towing stresses. Fourfoot leafsprings absorbed the driving and braking torque. These were secured to the chassis at the front and shackled at the rear. Rebound springs were of an unusual helical design.

In Britain the chassis cab version, which came complete with seat, acetylene headlight, two paraffin side-lamps and one taillamp, as well as a horn and the usual tools, retailed at £750.

Six different bodied models were available for civilian use — the normal cargo type, a dumper body with windlass, an oil tanker version, two for the timber industry, a stake platform and a roll-off lumber body.

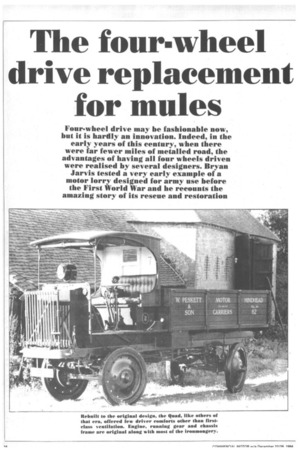

Richard Peskett's Jeffrey Quad has the normal cargo body but, like the cab itself, it is built from new wood to the original design and using most of the original hardware.

Restoring chassis number 70237 has taken his attention far and wide. The Beaulieu Autojumble provided some replacement parts but many others came from across the Atlantic.

Commonality between front and rear braking, steering and axle parts was an essential part of Thomas B. Jeffrey's build strategy and it also had its advantages when restoring a Quad after more than 30 years a'mouldering.

Engine parts were more of a problem, which is why Caterpillar valves had to be fitted. As the cylinders had deteriorated, they were ground out and Gardner LLK liners were used. The crankshaft had to be reground and new white metal bearings prepared, but the original pistons were quite serviceable once new rings were fitted.

The rescue of this outstanding First World War veteran enabled Richard to restore it to its former glory as the vehicle that finally replaced the four-mule team.