The 1)11

Page 22

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

C-tcri Uctlen steamer

by Trevor Longcroft

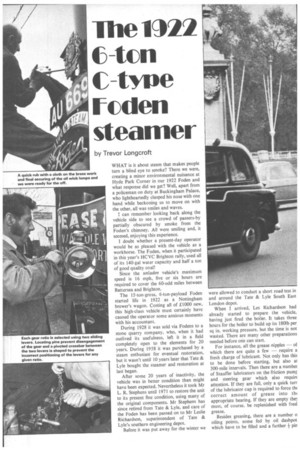

WHAT is it about steam that makes people turn a blind eye to smoke? There we were, creating a minor environmental nuisance at Hyde Park Corner in our 1922 Foden and what response did we get? Well, apart from a policeman on duty at Buckingham Palace, who lightheartedly clasped his nose with one hand while beckoning us to move on with the other, all was smiles and waves. I can remember looking back along the vehicle side to see a crowd of passers-by partially obscured by smoke from the Foden's chimney. All were smiling and, it seemed, enjoying this experience. I doubt whether a present-day operator would be as pleased with the vehicle as a workhorse. The Foden, when it participated in this year's HCVC Brighton rally, used all of its 140-gal water capacity and half a ton of good quality coal! Since the unladen vehicle's maximum speed is 16 mph, five or six hours are required to cover the 60-odd miles between Battersea and Brighton. The 15-ton-gross, 6-ton-payload Foden started life in 1922 as a Nottingham brewer's wagon. Costing all of £.1000 new, this high-class vehicle must certainly have caused the operator some anxious moments with his accountant.

During 1928 it was sold via Fodens to a stone quarry company, who, when it had outlived its usefulness, left it in a field completely open to the elements for 20 years, During 1958 it was purchased by a steam enthusiast for eventual restoration, but it wasn't until 10 years later that Tate & Lyle bought the steamer and restoration at last began. After some 20 years of inactivity, the vehicle was in better condition than might have been expected. Nevertheless it took Mr L. R. Stephens until 1971 to restore the unit to its present fine condition, using many of the original components. Mr Stephens has since retired from Tate & Lyle, and care of the Foden has been passed on to Mr Leslie Richardson, superintendent of Tate & Lyles southern engineering depot. Before it was put away for the winter we were allowed to conduct a short road test in and around the Tate & Lyle South East London depot. When I arrived, Les Richardson had already started to prepare the vehicle, having just fired the boiler. It takes three hours for the boiler to build up its 1801b per sq in. working pressure, but the time is not wasted. There are many other preparations needed before one can start. For instance, all the grease nipples — of which there are quite a few — require a fresh charge of lubricant. Not only has this to be done before starting, but also at 300 mile intervals. Then there are a number of Stauffer lubricators on the friction pun4 and steering gear which also requir( attention. If they are full, only a quick turr of the lubricator cap is required to force thi correct amount of grease into th( appropriate bearing. If they are empty the must, of course, be replenished with fres!

grease. Besides greasing, there are a number o oiling points, some fed by oil dashpot which have to be filled and a further pin of oil must be put into the rear axle differential gearcase every morning.

Once the boiler pressure had reached 180Ib per sq in, and all other preliminaries had been completed we were ready for the off — or so we thought. Unfortunately a gland on the high-pressure slide-valve shaft blew and it took a few minutes to make and fit a new one.

Once on the road, it quickly became obvious that the Foden Steamer was not a machine to be driven easily by the amateur. From watching Les, I gathered that two basic driver qualifications were a necessity. First, he should be able to carry out numerous operations simultaneously with each of his four limbs. Secondly, his fitting know-how must match his driving skill.

The engine, although by no means sophisticated, needs continual adjustment and lubrication en route if it is to run smoothly. During our short trip around London, we had to stop and adjust one of our main bearings (brasses) which had developed a knock. This bearing had only just been scraped-in, so it was inevitable that some adjustments would have to be made as it bedded down.

The compound steam engine has two cylinders, one which operates at high pressures, the other low. Two methods of engine operation are available: double high gear, and compound. The former involves feeding live steam from the boiler into both of the cylinders. The "double high gear", states the instruction book, should only be used where an increase in power is required for starting or manoeuvring in awkward places. Unnecessary continual use of the "double high" can damage the engine.

When an increased power output is not required, the alternative, lower output, compound gear can be engaged. Live steam is then fed to the high-pressure cylinder only; exhausted steam from the high pressure cylinder, now at a lower pressure, is fed into the low-pressure cylinder and re-used.

Stop to change Drive from the engine is transmitted to a three-speed gear train; there is no clutch, and all gear changes have to be complt.:ted with the vehicle stationary!

Starting from rest, the double-high gear is used and a ratio appropriate to the road conditions ahead selected. Once under way the engine can be dropped into compound drive, If it is necessary to change ratios, say to climb a hill, the vehicle is stopped and the required gear train and engine drive engaged. Should the gradient prove too steep, the vehicle must again be stopped before an alternative ratio can be selected.

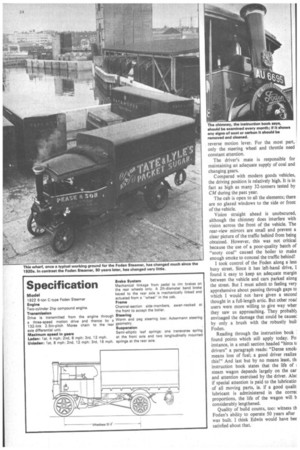

As previously mentioned, driver agility is a must if the vehicle is to be driven properly. From his seat the driver must control the boiler feed pump, the footbrake and firebox damper with his left foot, while his right foot is used to feed coal into the boiler. The hands are shared between numerous controls including the wheel operating the rear axle mounted band brake, the steering wheel, the compounding handle (throttle), the starting lever and the forward and reverse motion lever. For the most part, only the steering wheel and throttle need constant attention.

The driver's mate is responsible for maintaining an adequate supply of coal and changing gears. Compared with modern goods vehicles, the driving position is relatively high. It is in fact as high as many 32-tonners tested by CM during the past year. The cab is open to all the elements; there are no glazed windows to the side or front of the vehicle.

Vision straight ahead is unobscured, although the chimney does interfere with vision across the front of the vehicle. The rear-view mirrors are small and prevent a clear picture of the traffic behind from being obtained. However, this was not critical because the use of a poor-quality batch of "sooty coal" caused the boiler to make enough smoke to conceal the traffic behind! I took control of the Foden along a less busy street. Since it has left-hand drive, I found it easy to keep an adequate margin between the vehicle and cars parked along the street. But I must admit to feeling very apprehensive about passing through gaps tc which I would not • have given a second thought in a full-length artic. But other road users were more willing to give way wher they saw us approaching. They probabll envisaged the damage that could be causec by only a brush with the robustly buili Foden.

Reading through the instruction book found points which still apply today. Fo instance, in a small section headed "hints tc drivers" a paragraph reads: "Dense smok, means loss of fuel; a good driver realize this!" And last but by no means least, th instruction book states that the life of steam wagon depends largely on the car and attention exercised by the driver. Alsc if special attention is paid to the lubricatio of all moving parts, ie. if a good qualit lubricant is administered in the corm proportions, the life of the wagon will b considerably lengthened.

Quality of build counts, too: witness th Foden's ability to operate 50 years after was built. I think Edwin would have bee satisfied about that.