OPINIONS FROM OTHERS.

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

The Editor invites correspondence on all subjects connected with the use of commercial motors. Letters should be on one side of the paper only and typewritten by preference, The right of abbreviation is reserved, and no responsibility for views expressed is accepted.

Ford Operating Costs.

The Editor, THE COMMERCIAL MOTOR.

[2429] Sir,—It is because you specially invite comment on your table of operating costs that I am hoping you will find room your journal for a few remarks which I wish to make relating to the comparisons drawn by you between (a) the ton Ford costs and (b) the costs of " other " tonners. .

First, you assume that the cost of the road licence for all tonners is the same, whereas the Ford company feature as a sales argument that 'theirs is the only twiner carrying a £16 licence.

Secondly, you debit the " other " tonners with three times the " interest " charge which you are debiting against the Ford, from which it follows that if—as is generally the case—the average Ford ton outfit costs £150 to buy, you assume that " other " ton outfits cost £450 to buy, and base your calculations accordingly. Surely this is not right !

Thirdly, your rate of depreciation on all tonners being approximately the same, i.e., id. per mile, it follows that if (as per your " interest " figures) the Ford costs only one-third to buy, the Ford operator must buy and use up three Fords during the lifetime of one " other " tonner ; and the point arises : Where is the advantage in buying a Ford?

Fourthly, it would be interesting to know the basis on Which you calculate depreciation. Is it on the' estimated life of the machine in years (if so, how many years are taken'?) or have you assumed that a machine Will run a given number of miles before destruction, regardless of age? If the latter, it would appear, from your figures, that the life of the Ford is 72,000 miles at id. per mile depreciation, while the life of " other " tonners is about 216,000 miles, adding emphasis to the same point, i.e., where is the advantage in buying a Ford—the more so as it is admitted the Ford costs more to Maintain?

One also has a right to view wIth a deal of scepticism your assertion that the tyre wear on " other " tonners is nearly twice as much as on a Ford, because load and speed being the same, there is no apparent reason for such a big difference.—Yours faithfully, G. T. HUNT.

Making an Anti-freezing Solution.

The Editor, THE COMMERCIAL MOTOR.

[2430] Sir,—I have found a simple method of adding motor-glycerine to the water-cooling system, and recommend the following;—

Start up the engine and run until the water is hot. From the radiator draw off about a gallon of the hot water into a pail, unscrew the stopper of a tin of motorglycerine and allow the tin to stand in the hot water for a few minutes. Whilst the engine is still running, pour the contents of the tin of motor-glycerine into the radiator.—Yours faithfully, L. IL B. PEARCE, B.Sc. (London), A.I.C., F.C.S. London.

Modern Front-wheel-braking Practice.

The Editor, THE COMMERCIAL MOTOR.

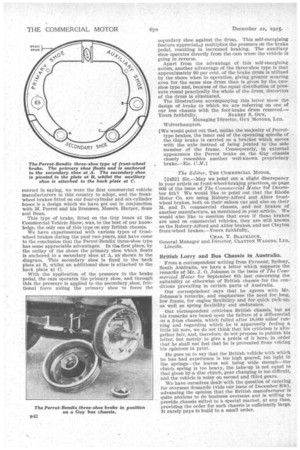

[24311 Sir,—We read with much interest the article in the issue of The Commercial Motor for December 8th under the above heading, and we regret a misstatement occurred, namely, that we fitted a certain proprietary make of front-wheel brake in common with a number of our competitors. This is incorrect. We also notice that you' do not illustrate or describe the Perrot-Bendix three-shoe type of brake, which, we believe we are correct in saying, we were the first commercial vehicle manufacturers in this country to adopt, and the frontwheel brakes fitted on our four-cylinder and six-cylinder buses is a design which we have got out in conjunction with M. Perrot and his lieensees, Messrs. Harper, Sons and Bean.

This type of brake, fitted on the Guy buses at the Commercial Vehicle Show; was, to the best of our knowledge, the only one of ,this type on any British chassis.

We have experimented with various types of frontwheel brakes during the past two years, and have come to the conclusion that the Perrot-Bendix three-shoe type has some appreciable advantages. In thcfr first place, by the outlay of the shoes the primary shoe which floats is anchored to a secondary shoe at A, as shown in the diagram. This secondary shoe is fixed to the back plate at B, whilst an additional shoe is attached to the back plate at C.

With the application of the pressure to the brake pedal, the cam operates the primary shoe, and through this the pressure is applied to the secondary shoe, frictional force aiding the primary shoe to force the secondary shoe against the drum. This self-energizing feature apprecial4 multiplies the pressure on the brake pedal, resulting in increased braking. The auxiliary shoe operates directly from the cam when the vehicle is going in reverse.

Apart from the advantage of this self-energizing action, another advantage of the three-shoe type is that approximately 90 per cent. of the brake drum is utilized by the shoes when in operation, giving greater wearing area for the same size drum than is given by the twoshoe type and, because of the equal distribution of pressure round practically the whole of the drum, distortion of the drum is eliminated.

The illustrations accompanying this letter show the design of brake to which we are referring on one of our bus chassis with the foot-brake drum removed.—

Yours faithfully, SYDNEY S. GUY, Managing Director, GUY MOTORS, LTD. Wolverhampton.

[We would point out that, unlike the majority of Perrottype brakes, the inner end of the operating spindle of the Guy brake is carried on a bracket which moves with the axle instead of being jointed to the side member of the frame. Consequently, in external appearance the Perrot brake on the Guy chassis closely resembles another well-known proprietary brake.—En. C.M.1 The Editor, THE COMMERCIAL MOTOR.

[2432] Sir,—May we point out a slight discrepancy in your article on front-wheel-braking practices on page 603 of the issue of The Commercial Motor for December 8th? We would like to point out that the Rhode Motor Co. are using Rubury-Alford and Alder frontwheel brakes, both on their saloon car and also on their M. and D. commercial chassis, and not brakes of another manufacture, as mentioned in your article. We would also like to mention that even if these brakes are used on commercial vehicles, they are still known as the Rubury-Alford and Alder brakes, and not Clayton front-wheel brakes.—Yours faithfully,

CHAS. T. BLACHLOCK, General Manager and Director, CLAYTON WAGONS, LTD. Lincoln.

British Lorry and Bus Chassis in Australia.

' From a coriespondent writing from Pyrrnont, Sydney, South Australia, we have a letter which supports the remarks of Mr. J. 0. Johnson in the issue of The Commercial Motor for September 8th last' concerning the suitability or otherwise of British chassis for the conditions prevailing in certain parts of Australia.

Our correspondent says that he agrees with Mr. Johnson's remarks, and emphasizes the need for long, low frame, for engine flexibility and for quick pick-up, as well as spring flexibility and endurance.

Our correspondent criticises British chassis, but as his remarks are based upon the failure of a differential on a 3-ton chassis, which failed after 18,000 miles' running and regarding which he is apparently feeling a little bit sore, we do not think that his criticism is altogether fair, and, therefore, do not propose to publish his letter, but merely to give a précis of it here, in order that he shall not feel that he is prevented from voicing his opinions in print.

He goes on to say that the British vehicle with which he has had experience is too high geared, too light in the springs—the leaves not being wide enough—the clutch spring is too heavy, the take-up is not equal to that given by a disc clutch, gear changing is too difficult, and the vehicle is noisy on second and third gears.

We have ourselves dealt with the question of catering for overseas demands (vide our issue of December 8th), advancing the opinion that the British manufacturer is quite anxious to do business overseas and is willing to provide chassis suited to a special market, at any time, providing the order for such chassis is sufficiently large. It rarely pays to build to a small order.