SPECIAL APPLIANCES FOR SPECIAL WORK.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

The Special Tool or Appliance Suitable only for One Particular Job is the Nafural Outcome of the Growth of the Large Fleet Formed from a Single Make of Vehicle.

WHEN the numbers of any particular product are substantial, the opportunity arises for the use of special tools and jigs for service in the garage and repair shop. Mr. H. G. Dunn, of Irthlingborough, is an exponent of this dictum, and as he has had a considerable experience in the maintenance of one particular make of commercial chassis—the• Leyland— also in toolmaking and maintenance work generally, he has concentrated for the present in the production of tools, jigs, machine tools, etc., specially designed for the Leyland make of engine, contending that, no matter

how well designed may be an adaptable machine, it must be more expensive in order to secure such adaptability and, even then, it will do the work no better than, and possibly not so well as, one designed and made especially for the job in hand. And, of course, such special appliances must appeal to the fleet engineer who has under his charge a number of vehicles all of one make. Even the garage proprietor and repairer can profitably develop a section of his works to deal solely with one make of chassis where there is a • number of such chassis in his neighbourhood.

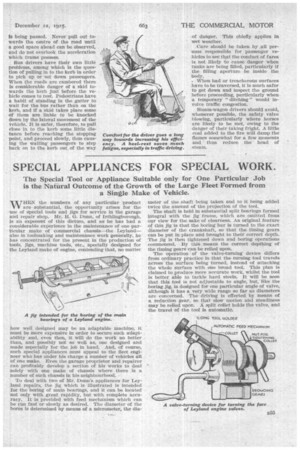

To deal with two of Mr. Dunn's appliances for Leyland repairs, the jig which is illustrated is intended for the boring of main bearings, and it can be located not only With great rapidity, but with complete accuracy. It is provided with feed mechanism which can be run fast or slowly as desired. The diameter of the bores is determined by means of a micrometer, the dia meter of the shaft being taken and to it being added twice the amount of the projection of the tool.

The shaft is held in substantial split bearings formed integral with the jig frame, which are omitted from our view for the sake of clearness. An original feature of this jig is that the boring bar is turned to the exact diameter of the crankshaft, so that the timing gears can be put in place and brought to their correct depth. The jig is then tightened down and boring operations • commenced. By this means the correct depthing of the timing gears' an be relied upon. The operation of the valve-turning device differs from ordinary practice in that the turning tool travels across the surface being turned, instead of attacking the whole surface with one broad tool. This plan is claimed to produce more accurate work, whilst the tool is better able to tackle hard steels. It will be seen that this tool is not adjustable to angle, but, like the boring jig, is designed for one particular angle of valve, although it has a very wide range so far as diameters are concerned. The driving is effected by means of a reduction gear, so that slow motion and steadiness may be relied upon. A split collet holds the valve, and the travel of the tool is automatic.