Collecting refuse with power and efficiency

Page 48

Page 49

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

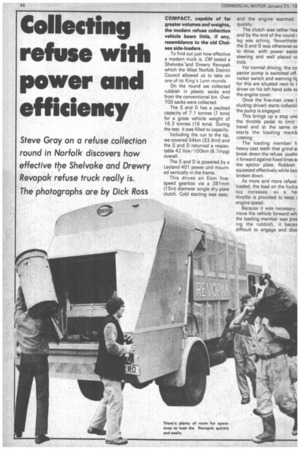

Steve Gray on a refuse collection round in Norfolk discovers how effective the She/yoke and Drewry Revopak refuse truck really is. The photographs are by Dick Ross

COMPACT, capable of far greater volumes and weights, the modern refuse collection vehicle bears little, if any, resemblance to the old Chelsea side-loaders.

To find out just how effective a modern truck is, CM tested a Shelvoke 'and Drewry Revopak which the West Norfolk District Council allowed us to take on one of its K4Ig's Lynn rounds.

On the round we collected rubbish in plastic sacks and from the conventional bin. Over 700 sacks were collected.

The S and D has a payload capacity of 7.1 tonnes (7 tons) for a gross vehicle weight of 16.3 tonnes (16 tons). During the test, it was filled to capacity.

Including the run to the tip, we covered 54km (33.6m1) and the S and D returned a respectable 42 litre/100km (6.7mpg) overall.

The S and D is powered by a Leyland 401 power unit mounted vertically in the frame.

This drives an Eton fivespeed gearbox via a 381mm (1 Sin) diameter single dry plate clutch. Cold starting was easy, and the engine warmed quickly.

The clutch was rather hea and by the end of the round r leg was aching Neverthele the S and D was otherwise ea to drive, with power assist steering and well placed cc trols.

For normal driving, the co pactor pump is switched off. rocker switch and warning li for this are situated next to t driver on his left hand side nE the engine cover.

Once the five-man crew ( cluding driver) starts collectin the pump is engaged.

This brings up a stop unc the throttle pedal to limit travel and at the same hr starts the loading memb rotating.

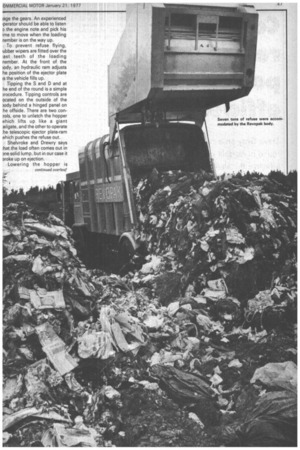

The loading member h heavy cast teeth that grind ai break down the refuse, pushii it forward against fixed tines al the ejector plate. Rubbish squeezed effectively while beir broken down.

As more and more reNse loaded, the load on the hydra lies increases, so a har throttle is provided to keep engine speed.

Because it was necessary move the vehicle forward whi the loading member was pref ing the rubbish, it becarr difficult to engage and dise

lage the gears. An experienced iperator should be able to listen D the engine note and pick his ime to move when the loading nember is on the way up.

To prevent refuse flying, ubber wipers are fitted over the :ast teeth of the loading nember. At the front of the ■ ody, an hydraulic ram adjusts he position of the ejector plate is the vehicle fills up.

Tipping the S and D and at he end of the round is a simple yocedure. Tipping controls are ocated on the outside of the )ody behind a hinged panel on he offside. There are two conrols, one to unlatch the hopper rvhich lifts up like a giant ,ailgate, and the other to operate he telescopic ejector plate-ram which pushes the refuse out.

Shelvroke and Drewry says :hat the load often comes out in ane solid lump, but in our case it aroke up on ejection.

Lowering the hopper is continued overleaf achieved by pulling the lever in the opposite direction, and retained by two substantial locking catches.

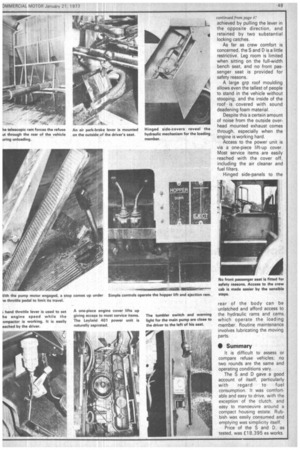

As far as crew comfort is concerned, the S and D is a little restrictive. Leg room is limited when sitting on the full-width bench seat, and no front passenger seat is provided for safety reasons, A large grp roof moulding allows even the tallest of people to stand in the vehicle without stooping, and the inside of the roof is covered with sound deadening foam material.

Despite this a certain amount of noise from the outside overhead mounted exhaust comes through, especially when the engine is working hard.

Access to the power unit is via a one-piece lift-up cover. Most service items are easily reached with the cover off, including the air cleaner and fuel filters.

Hinged side-panels to the rear of the body can be unlatched and afford access to the hydraulic rams and cams which operate the loading member. Routine maintenance involves lubricating the moving parts.

• Summary

It is difficult to assess or compare refuse vehicles; no two rounds are the same and operating conditions vary.

The S and D gave a good account of itself, particularly with regard to fuel consumption. It was comfortable and easy to drive, with the exception of the clutch, and easy to manoeuvre around a compact housing estate. Rubbish was easily consumed and emptying was simplicity itself.

Price of the S and D, as tested, was -El 8,395 ex works.