SUSPENSION: HOW IT MIGHT BE IMPROVED.

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

Some Experiences of a Designer of Commercial Vehicles and His Views on Various Systems.

MHE article dealing with suspen sion systems and their improvement which appeared in this journal on the 31st ult. deals fairly with most of the efforts that have been made towards advancement in this very, important matter. Unfortunately so few real efforts have been made that even a review of them does not throw much light on the• subject. What efforts have been made have not led to any substantial improvement ; not, however, because such efforts bore no promise of eventual success, but because the people who were paying for ex perimehtal work became tired of paying Mir what they considered was going to be just as beneficial to their rivals in business as to themselves. They said, "Why should we be pioneers? ' and from a business point of view the question is difficult to answer.

Strong patents are not easily procured in Matters connected with motors ; this can be proved by the comparatively few remunerative patents we have seen in connection , with the motor trade, especially when the magnitude of the business is taken into consideration.

My opinion is that while the matter rests with the firms who make the complete vehicle, we may expect any improvement to come very slowly and grudgingly. Could a strong patent be got for a real improvement, and that improvement made by a strong firm and sold to the whole trade, there would be every prospect of such a unit becoming Almost universally adopted, • as other units have been, but while it rests with a lot of competing firms, no one of which can ever hope to absorb the whole trade, we shall.see but slow improvement in this direction.

A Review of What Has Been Done.

Looking over the efforts that I have seen made, and have assisted in, and what I have done myself, also what has been written or suggested, I think that all experimenters and writers can abandon the idea that seems uppermost in-so many minds, namely, that a good springing system should enable a

vehicle to ride over a brick without bumping. To one brick that we meet with we find a million pot-holes. The depression, and not the protuberance, is what we have to deal with.

In your article you speak of a system that " becothes uncomfortable if rough roads be taken fairly fast." I am afraid that this trouble will always be with us, and that no matter what system is employed we shall never be able to go fast over rough roads. Comparing pneumatic tyres on buses and coaches with solid tyres on really bumpy roads, the latter make perhaps a more jarring vibration, but the former produce a bouncing that will often lift passengers bodily from their seats, and cannot be looked upon as a complete solution of the trouble ; at least, that is my experience.

The leaf spring forms a very convenient means for connecting the axle to the frame, as owing to its width and the fact that there is no joint interposed between it and the axle there is no possibility of rattle as with the fast-disappearing radius rod. If leaf springs were abandoned it would• be found difficult effectually to connect an axle to the frame, so we may expect such springs to remain, even if they be made lighter and be not asked to carry the whole of the weight.

There is no feature in a commercial vehicle that is surrounded with more debatable points than the mounting and appurtenances of the rear axle. One has to consider, not only the springing but the brake torque, the driving torque in any but the chain drive, and the thrust that drives the vehicle fors ward. The leaf spring has proved itself, beyond all . doubt, able to withstand all ' these stress, so whatever takes itS place must do the same.

Looking Backward.

In trying to solve this problem, like most other problems, one must look back on what has gone before to seek for information that may inspire or lead to an improvement.

I remember having a patent device fitted to a shooting brake, which consisted of a barrel containing a spring like those used in a gramophone, but, of course, stronger. The barrel was connected to the chassis and the spring was anchored to it, whilst the spindle projected and was fitted with a crank, to which was attached the shackle of an ordinary spring. The sketch is from memory and may not be correct in all details. The spindle was mounted in plain bearings. , A careful inspection of the behaviour of this arrangement showed that when travelling over a rough road, such as bad granite setts, there was only a sluggish movement of the crank at intervals, when some unusually prominent sett or deep depression was met. The experiment was then tried of mouftting the spindle on ball bearings, and the reiwit was most extraordinary—the oscillatioas of the crank were so rapid that the eye could hardly follow them when going over the same setts ; in short, it seemed to give to the individual setts and entirely to remove the dither from the frame.

I believe this device failed owing to the difficulty of finding a coil spring that would stand up to the work, but it left me with theiimpression that the ,friction of shackle joints was, to a large extent, responsible for the sluggishness of leaf springs, and that if anti-friction bearings could be introduced in shackles we should have springs that w,ould respond immediately 10 un even roads, instead of, as at present, responding when the pot-hole is passed and the frame has dropped a distance equivalent to the depth of the hole. This opinion has been strengthened by experiments made with well-lubricated and badly lubricated shackle pins, for it has been found that well-oiled pins and well-lubricated springs reduce vibration, whilst rusted-up or locked shackle pins increase it.

Ordinary anti-friction bearings, such as ball or roller, would be unsuitable to shackles, but• it has been suggested that the Morse chain rocker might be tried, as it would be practically a knife edge as used on heavy weighing machines, and which, whilst being practically frictionless, will bear great loads.

An Interesting Experiment.

In a moment of weakness—or shall I say, temporary insanity?—I once carried out an experiment with a 3-ton lorry by designing a new form of springing. This experiment, although promising, was cut short for the reasons mentioned above, namely, the reluctance of my firm to be pioneers, but the experience gained may be of value if anyone has the courage to follow up the methods employed.

A Suggested Suspension System.

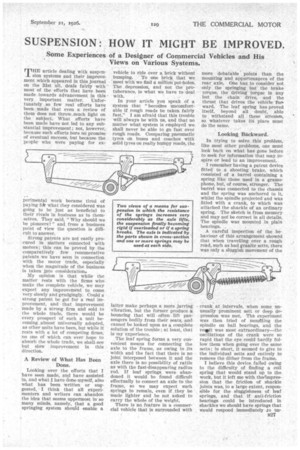

The sketches which are reproduced should make the idea clear, as the spring when used in connection with a double shackle is most inconstant, and adjusts itself to the load, the suspension finally becoming rigid if greatly overloaded or should the spring break. A plurality of helical springs might be used, as this would reduce risk. Light leaf springs might be retained to steady the chassis sideways, and a nut mig it even be provided for adjustment. Such a springing would greatly reduce the inertia experienced with leaf springs, and thereby enable the springs to act when the wheels are in the pot-hole.

Other Devices I Have Tried.

Regarding the many suspension devices that I have tried at various times, and some of which have been offered to the trade, I make the following comments, which, of course, must be looked upon as being my personal opinions : Spring wheels.—I have never seen one yet that I thougnt any good, and this is borne out by the fact that few are in service.

Springs between frame and body. —A slight reduction of vibration is sometimes experienced, but this is not sufficient to warrant the cost.

Independently sprung wheels.— A slight reduction of vibration has been noted with these, but this was mainly due to the springs employed being unusually flexible, and the tyres 7rather on the soft side when the demonstrations were made. This plan entails a lot of joints, especially when applied to rear wheels, and generally I do not think it worth while for ordinary purposes, although, of course, it may have specific applications, Pneumatic cushions between main springs and frame.—I have no great belief in these, although I understand that some are being used successfully on certain units of a bus fleet. When such cushions are employed it is essential to relieve them from friction and stresses other than that due to load.

Compressed air in cylinders with pistons.—This is the only system that has impressed -me as being a real improvement, but will it ever prove a practicable proposition on commercial vehicles? Compressed air has a way of going anywhere but to the points where it is wanted unless everything is absolutely in order —and how often does one find this . in commercial vehicles?