Flexibility the key at CF Rights

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

ICE my previous visit last ir to Imperial Coachbuils Ltd at Basildon, Essex, company has changed its ne to Crane Fruehauf lids Ltd. This reflects a ler range of body consction that the plant now lertakes.

The Imperial name is retainin the Imperialite body still ng produced, providing a je carrying capacity in the ler-30cwt unladen range and refore requiring no carrier nce.

The bodies I had come to look this time, however, fell in a her weight bracket — mostly to 7.49 tonnes (7.38 tons) rv in standard form and aptly ned the City Delivery range. 3CD body is available in three iic-overall widths, 2.18m (7ft sin) 2.32m (7ft 71/4in) and im (8ft 11/4in) and will vary 3ending on the individual ]ssis it has to match up with.

)uble advantage Prior fitting approval is Ight before fitment to any N range of chassis from the iicle manufacturers. This has louble advantage:

It usually enables CF to hold a nk stock of chassis;

and any unforseen irregularconcerning concerning the compatibility

the two can be resolved fore the final product reaches a customer.

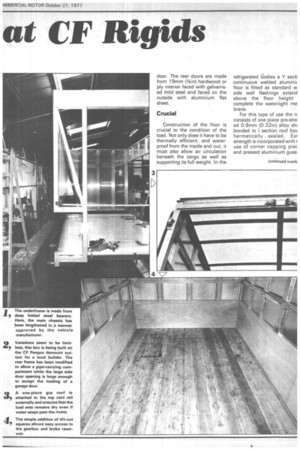

The underframe is made from number of 76mm (3in) deep ded steel bearers for strength, isitioned at 0.46m (18in) ntres, which are then covered 22mm (Vain) tongue and oove softwood flat floor and ay, in turn, be covered by steel ecker-board plate or some her material of the customer's loice.

Bulkhead and side panels are lilt complete. They include terlocking alloy extruded split prners posts used to join the le to the front bulkhead and e rear frame, while 19swg flat loy sheets in 1.24m (49in) idths are employed too as an Aside skin. Vertical posts 152mm (6in) wide are placed at 0.6m (2ft) centres and attached to a top cantrail and an eight-inch mainside rail along the lower edge.

TI R spec The outer skin is attached to the vertical pillars by a double row of solid rivets, which -complies with the standard required for TIR spec, and assembled as separate panels before being brought together.

A one-piece grp sheet is used to cover the box and is fixed to the top cant rail outside the cargo area. Built on a flow-line principle, this type of unit construction lends itself to easy adaption for specific load carrying requirements.

Extra height or length to the rear to suit chassis extensions can be easily provided and, with a little extra effort, so, too, can a Luton extension. Wide or narrow openings allow use of shutter doors at the side, while at the rear, roller or double doors are offered.

Further deviations from the basic box can also be accommodated in the flow-line assembly plant. The interior, however, is where it is usual to find the most variations in specification.

Special plugs Partial laminated wood cladding, or fully lined with aluminium sheet may suit one operation better than another. Tie rails and floor rings, or perhaps a full load lock system,may be incorporated.

Some chassis may require that floor panels be included — nothing, it seems, is impossible.

The same basic construction forms the basis of the insulated van body. Special plugs made of a low thermal conductive material are inserted at intervals into the side pillars, roof and floor bearers, on which the inner lining is mounted.

The most efficient way in which to insulate this type of body is with spray-on polyurethane foam. When the -foam hits the back of the outer panels, the first few layers of cells compact and, in effect, seal off the insulator, which is necessary to stop any condensation forming.

The depth of insulation can be built up to 133mm (5%in) on the roof panel where meat

reinforcement rails are fitted, but will vary on other panels dependent on the thermal performance required. By spraying on the foam, every little crevice can be filled. Before the insulation process is started, however, a test cube is formed and analysed to ensure ttle, continuity of the molecular] form.

Seepage danger

Once the foam has cured, it is trimmed off to the depth offset. by the plugs so that the inner panels can be added. Where meat rails are asked for, reinforcement is built into the roof to stand up to a full 20.3 tonnes (20 tons) in suspension. Water and hot air seepage are the two main enemies to a reefer, so to make sure the box is airtight and watertight all joints are double sealed with bitumastic.

Door seals are just as important and must provide an air tight compression seal. Crane Fruehauf has developed its own multi-wedge convulated triple door seal to provide a 101mm (4in) deep cushion around the periphery of each door. The rear doors are made from 19mm (3/4in) hardwood or ply interior faced with galvanised mild steel and faced on the outside with aluminium flat sheet.

Crucial

Construction of the floor is crucial to the condition of the load. Not only does it have to be thermally efficient, and waterproof from the inside and out, it must also allow air circulation beneath the cargo as well as supporting its full weight. In the refrigerated bodies a Y secti continuous welded aluminii floor is fitted as standard w side wall fleshings extend above the floor height complete the watertight me bran e.

For this type of use the r( consists of one piece pre-stre ed 0.8mm (0.32in) alloy shi bonded to I section roof bov hermetically sealed. Exi strength is incorporated with use of corner capping piec and pressed aluminium guss,

tie in the roof, front and side us together.

Although CF Rigids Ltd ters for the individual specifition, the company's main urce of revenue, natural comes from the larger erators who would normally luire a batch of one type unit, The Post Office Telemmunications own spec for rew-cab/mobile workshop sed on the Bedford TJ 700 Issis cab) falls into this egory and during my visit last ek I was able to see a batch ing down the line.

Before any bodywork can be Jed, the rear of the existing ) has to be cut away. In this tance, a timber frame had an specified. To protect it m rotting, all the joints have be sealed.

To reduce the drumming of large panels, a problem nmon with many of the iss-produced panel vans, the me is lined with a sticky ,ulation material which bonds two together on contact. In itrast to the normal CF mtice of overlapping panel nts, the spec again differs, ling for butt joints protected th a moulding.

Winning an order of this type an indication of its cornpetieness, for CF Rigids are only e of many on the Post Office ider list. Factories at Bolton d West Lothian in Scotland ;eive the pre-built body panels idy for assembly from the in factory at Basildon. But :al demands are met by ying in materials locally. In s way, CF Rigids are able to

wide a nationwide service. r, • Bill Brock V