Demountables ha (almost) all the aii!

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

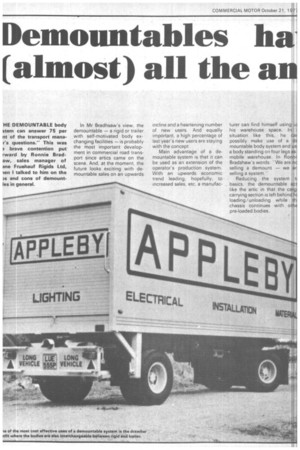

HE DEMOUNTABLE body stem can answer 75 per nt of the transport mariar's questions." This was

brave contention put rward by Ronnie Bradaw, sales manager of ane Fruehauf Rigids Ltd. ten I talked to him on the 3S and cons of demountles in general.

In Mr Bradhsaw's view, the demountable — a rigid or trailer with self-motivated body exchanging facilities — is probably the most important development in commercial road transport since artics came on the scene. And, at the moment, the future looks exciting with demountable sales on an upwards incline and a heartening number of new users. And equally important, a high percentage of last year's new users are staying with the concept.

Main advantage of a demountable system is that it can be used as an extension of the operator's production system. With an upwards economic trend leading, hopefully, to increased sales, etc, a manufac turer can find himself using his warehouse space. I situation like this, he possibly make use of a mountable body system and a body standing on four legs mobile warehouse. In Ro Bradshavv's words. -We are selling a demount — we ar selling a system.'" Reducing the system ti basics, the demountable act like the artic in that the carg, carrying section is left behind to loading /unloading while chassis continues with o he pre-loaded.bodies. Operating principle

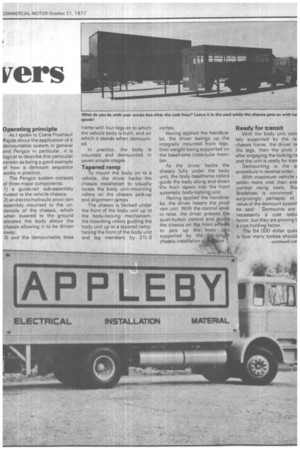

As I spoke to Crane Fruehauf Rigids about the application of a demountable system in general and Pengco in particular, it is logical to describe this particular version as being a good example of how a demount sequence works in practice. .

The Pengco system consists of three major components: 1) a guide-rail sub-assembly riveted to the vehicle chassis; 2) an electro-hydraulic pivot ram assembly mounted to the underside of the chassis, which when lowered to the ground elevates the body above the chassis allowing it to be driven away; 3) and the demountable base frame with four legs on to which the vehicle body is built, and on which it stands when demounted.

In practice, the body is mounted and demounted in seven simple stages.

Tapered ramp

To mount the body on to a vehicle, the driver backs the chassis installation to visually locate the body unit-mounting rollers on the chassis pick-up and alignment ramps.

The chassis is backed under the front of the body unit up to the body-locking mechanism, the mounting rollers guiding the body unit up to a tapered ramp, raising the front of the body unit and leg members by 21/2-3 inches.

Having applied the handbrake, the driver swings up the integrally mounted front legs, their weight being supported on the baseframe cross tube member.

As the driver backs the chassis fully under the body unit, the body baseframe rollers guide the body along and down the front tapers into the front automatic body-locking unit Having applied the handbrake, the driver lowers the pivot ram unit. With the control lever in raise, the driver presses the push-button control and pivots the chassis on the front wheels to pick up the body unit supported by the 11-lenglh chassis installation s me.

Ready for transit

With the body unit corn tely supported by the ra chassis frame, the driver ra the legs, then the pivot r after engaging the locking ra and the unit is ready for tran Demounting is the si procedure in reverse order.

With maximum vehicle sation more vital than eve combat rising costs, Rol Bradshaw is convinced surprisingly perhaps) of value of the demount system he said "Demounts are necessarily a cost redui factor, but they are proving t a cost holding *tor."'

The 64,000 dollar ques is how many bodies should continued ove

)rator have for each vehicle? :F's opinion, the ideal ratio is ) in three; one in transit, one ng loaded and one being oaded.

4t the moment, there is no h thing as a standard body. Ronnie Bradshaw said: "If manufacturers of shoes, oil, is, etc would standardise on at they wanted, then it would ideal because it would mean t different customers could each other's bodies."

'But what about the livery?" ked.

o problem'

"No problem" said Ronnie. (hat's wrong with having a 11 livery — one side for one npany and the other custo r having the reverse side?" only problem I can envisage h this idea is the confusion it iId cause with witnesses if the iicle was involved in an ident!

"Anyway," said Ronnie dshaw, "The possible say s with the idea are far more asing to the board than a or livery problem."

Theoretically, the 7.3m .ft) body is the most versatile :ause it gives an opening for iy standardisation between chassis and a trailer while not being too large in rigid form for access to more restricted premises.

While on the subject of standardisation, this is an area where the artic /semi-trailer has the demount system cold. With few exceptions, any tractive unit can couple up to any semi-trailer as far as the actual mechanism goes — ignoring length problems for the moment. The demountable concept however is still hampered by a lack of standardisation as often body "X" is only compatible with system "X" and no other.

Two pitfalls

Any idea, however good, has a couple of associated difficulties and, according to CF Rigids, there are two possible pitfalls which must be considered before getting in on the demountable act.

The first must is to make sure that the premises are right. Ronnie Bradshaw recalled that people had inquired about the possibility of using demounts but had to be advised against it because of lack of room at their premises. When an operator goes demountable, more space is required immediately. A good rule of thumb is to allow twice the length of the vehicle as an estimate for the space required in the yard.

The other thing to watch for is the terrain. With a derhountable, the type of ground is very important. Take camber, for instance. If the ground has a severe camber, the situation could arise where you couldn't get the body on or off.

Spreader plates

Can a demountable be used on soft ground, for example on tipper work? The strict answer is no, although CF Rigids can supply spreader plates if absolutely necessary.

Going for demountable bodywork means an inevitable weight penalty. In the case of the 24ft body, it puts around half-a-ton on to the chassis with an extra penalty thrown in because the body itself will require a stronger base frame.

If a vehicle carrying a perishable cargo (or any load under some form of "penalty" delivery) breaks down, a demount vehicle can be swapped so the load carries on. This also applies to an artic /semi-trailer combination, but a rigid in these circumstances could cause problems necessitating transhipment of the load.

The versatility of the de

mountable system can be illustrated by two specific examples. The one body in transit, one being loaded and one being unloaded concept is well known, but how about these variations?

Phone facilities

The Potato Marketing Board needed an on-site showroom for use at agricultural shows. The detail requirements included a floor area of 56sqm (600sqft) and a kitchen as well as water and telephone facilities. Using a CF Pengco P70 system as a base, mobile showroom builder Masters (of Beckenham) Ltd came up with the idea shown here which folds away to be carried on a Bedford KC six wheeler.

Denys Fisher Toys jumped on the demountable bandwagon. to solve a personnel problem — with a demountable bus.

Each morning, a 52-seater bus collects the employees from Wetherby, Tadcaster, Collingham and Boston Spa and when they have been taken to work, the bus body is swapped for a cargo module and the Commer reverts to goods distribution. At the end of the day, the bus body goes back on to take everybody home.

• Graham Montgomerie