HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble,

568.—Facilitating the Replacement of the Camshaft on the Sentinel Steam Wagon.

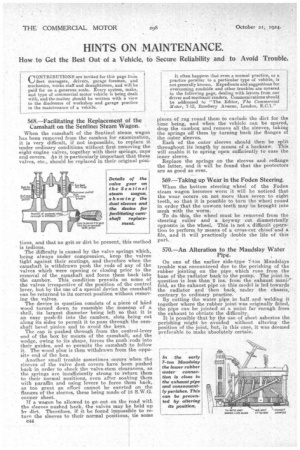

When the camshaft of the Sentinel steam wagon has been removed from the canabox for examination, it is very difficult, if not impossible, to replace it under ordinary conditions without first removing the eight engine valves, together with their springs, caps and covers. As it is particularly important that these valves, etc., should be replaced in their original posi tions, and that no grit or dirt be present, this method is tedious.

The difficulty is caused by the valve springs which, being always under compression, keep the valves tight against their seatings, and therefore when the camshaft is withdrawn push the rods of any of the valves which were opening or closing prior to the removal of the camshaft and force them back into the carnbox. This condition prevails on some of the valves irrespective of the position of the control lever, but by the use of a special device the camshaft can be returned to its correct position without removing the valves.

The device in question consists of a piece of hard wood turned down to resemble the nosecap of a shell, its largest diameter being left so that it is an easy push-fit into the canabox, slots being cut along its sides to permit it to pass through the camshaft bevel pinion and to avoid the keys. The cap is pushed through from the control-lever end of the box by means of the camshaft, and the wedge, owing to its shape, forces the push rods into their guides, and so permits the camshaft to follow it. The wood plug is then withdrawn from the opposite end of the box.

Another small trouble sometimes occurs when the sleeves of the valve dust covers have been pushed back in order to cheek the valve-stem clearances, as the springs are insufficiently strong to return them to their normal positions, even after soaking them with paraffin and using levers to force them back, as too great an effort cannot be exerted on the flanges of the sleeves, these being made of 18 S.W.G. cooper sheet.

If a wagon be allowed to goout on the road with the sleeves pushed back, the valves may be held up by dirt. Therefore, if it be found impossible to return the sleeves to their normal positions, tie some c44 pieces of rag round them to exclude the dirt for the -time being, and when the vehicle can be spared, drop the eainbox and remove all the sleeves, taking the springs off them by turning back the flanges of the outer sleeves.

Each of the outer sleeves should then be split throughout its length by means of a hacksaw. This will enable it to spring open sufficiently to ease the inner sleeve.

Replace the springs on the sleeves and reflange the latter, and it will be found that the protectors are as good as ever.

569.—Taking up Wear in the Foden Steering.

When the bottom steering wheel of the Foden steam wagon becomes worn it will be noticed that the wear occurs on not more than seven to eight teeth, so that it is possible to turn the wheel round in order that the unworn teeth may be brought into mesh with the worm.

To do this, the wheel must be removed from the steering roller and a keyway cut diametrically opposite in the wheel. This is not a difficult eparation to perform by means of a cross-cut chisel and a file, and it will practically double the life of this part.

570.—An Alteration to he Maudslay Water Pipe.

On one of the earlier side-type 7-ton Maudslays trouble was encountered due to the perishing of the rubber jointing on the pipe which runs from the base of the radiator back to the pump. The joint in question is less than 2 ins, from the exhaust manifold, as the exhaust pipe on this model is led towards the radiator and • then back under the chassis, contrary to ordinary practice. By cutting the water pipe in half and welding it together Where the rubber joint was originally fitted, the pipe can be jointed at a point far enough from the exhaust to obviate the difficulty. It is possible that by the use of sheet asbestos the perishing might be avoided without altering the position of the joint, but, in this case, it was deemed preferable to make absolutely certain.