NEW TOOLS FOR THE GARAGE AND WORKSHOP.

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Details of Eouinment Designed to Facilitate Repair Jobs and to Reduce Maintenance Costs

MANY TOOLg and applamaes were shown at Olympia and the White City this year which are not only of use to the garage -proprietor, but should be worthy of the consideration of the owner of large fleets of commercial motors. Those leaders in the production of such appliances, Lake and Elliot, Ltd., of Braintree, have added several new features to their already large range, of equipment tools: In mock cases these appliances are specially rib-. signed for use in connection with Ford repairs, but in Many cases the prineipies contained in the devices can be applied with advantage to other types of vehicles.

Tho special form cof melting-pot used for Babbitting bearings and the method, of casting calls for special attention, as by its use a sound casting can always be relied -avian. Fig. 1 shows the melting-pot on the heating apparatus, -which is arranged for gas; the heater is made alse,in a form suitable for use 'with a

blow-lamp. Fig. 2 shows a sectional view of the pot., and it will be seen that this design differs from others, in the way in which the melted metal is introduced into the mould. The pot has a conical recess at the bottom, which is intended to berested an a male cone formed on the jig for casting the metal into the bearing.

When the. pot is resting by its own weight on the Mould, the plunger {A) can be raised by lifting the cross-bar (B) with the fingers. This allows a discharge of the metal from the bottom of the -pot to enter tho 'runner hole in the mould. The metal flows to the part required, arid caw escape only through the riser hole shown at C. By this arrangement the soundest metal at the bottom of the pot, perfectly free from dross, enters the mould. The advantage of this method over the pouring from the top of a ladle needs no comment. Not only is a sound casting assured, but the weight of the head of

metal ia the pot forces the metal into the Mould, which produces practically a die casting. Any impurity in the mould will come out with the air through the riser hole. Apart from the advauta.ges mentioned above there is -very little waste of metal 'when pouting.

The neat devices shown by this concern for the removal of bushes are of special interest-, as there has always been some difficulty.•?in removing Vaal:esin certain circumstances. Fie3 shows the device .in operation,' so that little description is needed. The punch for forcing the bush out is split, and is contracted and held in that position by thering showo, which enables it to enter the hole.

As it passes through the hole the ring is arrested, thus allowing the split portion to spring outward and so engage the bush to be removed.

A very useful garage press'avith novel features is produced by the same concern. It has the usual screw and wheel, but is provided with an arrangement -whereby a long lever can be■brought bear on the wheel bymeans of a bell crank acting On a number of etude cast on the wheel, and so, by a step-by-step motion, great Tower can be imparted. to the wheel. Lake and Elliot, Ltd., make a great variety of devices which would occupy too much space for us to describe in detail, hut they can all be found in the very complete catalogue which they publish.

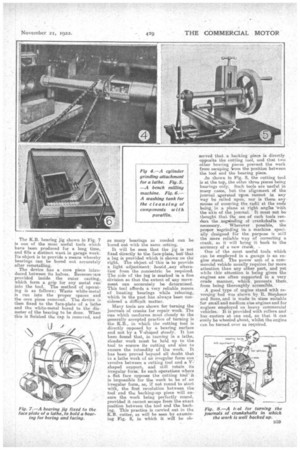

Mann and Egerton, Ltd., of Norwich, exhibited some of the best made and most useful machines for garage use. Among these was a cylinder-grinding attachment for ordinary lathes, shown in Fig. 4, which can, if desired, be used in a vertical position. The range of operation is from zero to an amount of eccentricity of 4 ins.; thus, by using a 4-in, wheel a cylinder of 8-in, bore can be •reached. Without, the extension a cylinder of.14 ins, depth can be ground, and with the extension supplied, a cylinder 22 ins, deep can be reached. The worm and wheel shown regulates

the eccentricity, The • atta.clunent is made in first-class style as regards 'material and workmanship. To give this device a fair opportunity of showing its merits we should only advise its use where a thoroughly reliable lathe is available.

-The. bench milling machine shown in Fig. 5 is an extremely useful tool for small users -who haVe not a milling machine installed., It has a hardened and ground hollow mandrel with taper to 'receive arbor. The vertical adjustment is 6 ins.. the surface of the table is 6 ins. by 2.0 ins., with a travel of 12 ins. maximum. The crass slide has a movement of 6 ins., which is ample for any jobs likely' to be done in a garage. The mandrel being hollow, end-mills can be used. The arbor for cutters is 1 in, and of high-tetision steel. The workmanship and material are of the best, and, as the machine can he driven by either hand or power, -it should find a plate wherever any replacement parts ate likelyto be Made, as it will mill splined shafts, square or hexagonal parts, and cut key-ways either for ordinary keys or Woodruff keys.

The washing tank shown clearly in Fig. 6 is a very neat and useful appli; Once, and, where many parts have to be dealt with, will save its cost in paraffin in a very short time It consists of a tank with a strong false bottom on which the article to he cleaned rests. A force Pomp and flexible hose are fitted which will direct a, jet of paraffin at the object with some considerable force, and so remove all dirt. A strainer ancl settling tank are provided ; also splash guards, as shown. It is mounted on wheels, so that it can be brought to any part where cleaning is needed. Besides the devices mentioned above, this firm make many useful garage appliances, descriptions of which will be found in their catalogue. The K.B. hearing jig shown in Fig. 7 is one of the mos& useful tools which have. been produced for a long time, and fills a distinct want in garage work. Its object is to provide a means whereby bearings ean be bored out accurately • after remetalling.

The device has a core piece introduced between its halves. Recesses-ran provided inside the outer casting, which form a grip for any metal sun into the tool, The method of operating is as follows: Waste white-metal is run into the proper spaces and the core piece removed. The device is then fixed to the face-plate of a lathe and the white-metal bored to the diameter of the bearing to be done. When this is finished the cap is removed, and as many bearings as needed can be bored out with the same setting.

It will be seen that the jig is not fixed directly to the face-plate, but that a lug is provided which is shown on the right. The object of this -le to provide a light adjustment: hould ..any alteration Irons the concentric be required. The side of the lug is marked in a fine division so that the extent of any movement can accurately be determinedThis tool affords a very reliable means of locating hearings while reboring, which in the past has always been considered a difficnIt matter.

Many tools are shown for turning the journals of cranks for repair work. The one which conforms most closely to the generally accepted practice of turning is the K.B., in which the mining tool is directly opposed by a• bearing surface and not by a lirshaped steady. It has been foundthat, in turning in a lathe, slender work must be held up to the tool to ensure its cutting and also to ensure the rotundity of the work. It has been proved beyond all doubt that in a lathe work of an irregular form can revolve between a cutting tool and a shaped support, and still retain its irregular form, In snch operations where a, flat face opposes the cutting teal' it is impossible for the work to be of an irregular form, as, if not round to start with, the first revolution between the tool and the backing-up piece will ensure the work being perfectly round, provided it cannot escape from the exact position between the tool and the backing. This practice is carried out in the K.S. cutter, as will be seen by examining Fig. 8, in which it will be oh served that a backing piece is directly opposite the cutting tool, and that two other bearing pieces prevent the work from escaping -!4'0111 the position between the. tool and the bearing piece.

/es shown in Fig. 8, the cutting tool is at the top, the other three pieces being bearings only. Such tools are useful in many cases, but the alignment of the jomeral operated ilrion cannot in any way be relied upon, nor is there any • meaus of ensuring the radii at the ends being. in a plane at right angles 'with the alis of the journal. It must not be thought that the 1180 of such tools renders the .rogeinding of crankshafts 1.111neee,ssaay. Wherever possible, the propetr vegeinding in a machine specially designed fin the purpose is still the more reliable way of correcting a crank, as it will bring it back to the accuracy of a• new crank.

One of the most useful tools which can be employed in a garage is an engine stand. The power unit, of a commercial vehicle usually requires far more attention than any other part, and yet while this attention is being given the engines are often supported in a very crude manner, which . prevents them. from being thoroughly accessible. A good type of engine stand with reversing •bed was shown by R. Stehene

and Sons, and is made in suitable for small and medium size engines and for engines employed on heavy commercial vehicles. It is provided with rollers and hasca.sters at One end, so that it can easily be wheeled about, whilst the engine can be tinned over as required.