A NEW TAPER ROLLER BEARING.

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Made in Great Britain, it is Claimed for the British Bock Bearing that it Includes Various Detail Improvements over Earlier Forms.

TEE taper roller bearing has one outstanding feature, arid that is its ability to carry an ordinary radial load and a very liberal amount of thrust load. Parallel. rollers will carry radial load, perihnps, better than !any. other class of bearing, but parallel rollers will carry no thrust load whatever; consequeutly, separate thrust bearings have to be provided which add to the number of parts, the cost arid weight.

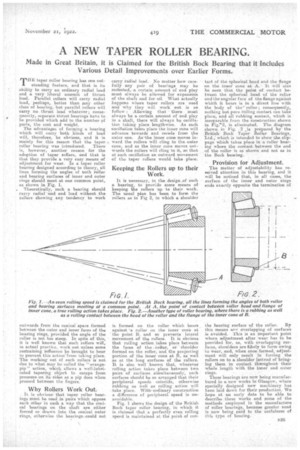

The advantages of forming a bearing which will carry both kinds of load will, therefore, be obvious, and it is mainly for this reason that the taper roller bearing was introduced. There is, however, another reason for the adoption cif taper Toilers, and that is that they provide a very easy means of adjustment for wear. In a taper roller bearing designed according to theory, all lines forming the angles of both roller and bearing surfaces of inner and outer rings should meet at one common point, as shown in Fig. 1.

Theoretically, such a bearing should carry radiarand end load without the rollers showing any tendency to work outwards from the conical space formed between the outer and inner faces of the bearing rings, provided the angle of the roller is not too steep. In spite of this, it is well known that such rollers will, in actual practice, work out unless some restraining influence be brought to bear to prevent this action from taking place. The working. out of such rollers is not due to what may be called the " orangepip" action, which allows a well-lubsiceded tapering object to escape from pressure on its sides as a pip does when pressed between the fingers.

Why Rollers Work Out.

• It is obvious that taper roller hear. ings must he used in pairs which oppose each other in such a way that the conical bearings on the shaft are either forced or drawn into the conical outer rings, othenvise the bearings could not

carry radial load. No Matter how carefully any pair of bearings may be indented,. a .certain amount of end play must always be allowed for expansion of the shaft and for oil. What actually happens where taper rollers are used and Why they will work out is as follow : Allowing that there must always be a certain amount of end play in a shaft, there will always be oscillation taking place lengthwise. As each oscillation takes place the inner cone will advance towards and recede from the outer one. As•the inner cone moves

inward the rollers will •cling to the outer cone, and as the inner cone moves outwards the rollers will cling to it, so that at each oscillation an outward movement of the taper rollers would take place.

Keeping the Rollers up to their Work.

It is necessary, in the design ,of such a bearing, to provide some means of keeping the rollers up to their work. The usual plan has been to form the rollers as in Fig 2, in which a shoulder

is formed on the roller which bears against 'a collar on the inner cone at 'the point 13, and so prevents lateral movement of the rollers. It is obvious that rolling action takes place between the faces of the . collar, or shoulder formed on the roller, and the projecting portion of the inner -cone at 13, as well as at the long surfaces of the rollers. It is also well -known that, wherever rolling action takes place between two pairs of surfaces simultaneously, such surfaces should be so arranged that their peripheral speeds coincide, otherwise rubbing as well as rolling action will take place. With' ordinaryconstruction a difference of peripheral speed is unavoidable.

Fig. 1 shows the design of the British Bock taper seller, bearing, in which it is claimed that a perfectly even rolling speed is maintained at the point of con tact of the spherical head and the flange on the inner cone at, A. It will also be seen that the point of contact between the spherical head of the roller and the angular face of the flange against which it bears •is in a direct line with the body of the' roller consequently, nothing but pure tolling contact ran take place, and all tubbing oontact, which is inseparable from the construction shown in Fig." 2, is eliminated. The diagram shown in Fig. . 2 is prepared by the British. Beck Taper Boller Bearings, Ltd.; which is intended to show the slippage which takes place in a roller bearing where the eentact• between the end of the roller is as shown and not as in the Bock bearing.

Provision for Adjustment.

The matter of acijustability has received attention in this hearing, and it will be noticed that, in all cases, the surface of the inner and outer rings ends exactly opposite the termination of the bearing surface of the roller. By

this means any Overlapping of surfaces is avoided. This is an important point where adjustment. after ;wear has to be provided for, as, with overlapping surfaces, shoulders are likely to form owing to wear, and, when once formed, adjustment will only result in forcing the rollers on to a shoulder instead of bringing them in contact thsonghout their whole length with the inner and outer rings.

These bearings are now being manufactured in a new works in Glasgow, where specially designed new machinery has been laid down for their production. We hope at an early date to be able to describe these werks and some of the methods employed in the manufacture of roller bearings, because greater need is now being paid to the usefulness of this type of bearing.