A CRANE of Universal Application

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

IN docks, railway yards and factories where the lifting and transporting of goods is an everyday and all-day occurrence, a mobile crane has to move about amid ever-changing obstructions, and often a considerable amount eif time is wasted because one job is at one end of the yard and the next some two or three hundred yards away. The straight journey between the two points is, comparatively speaking, of little importance, but the time spent at each cud of the trip in manceuvring for position, prior to lifting the load, often exceeds by a considerable margin the duration of the straight journey.

A new design of crane, .knowri. as the Versatile, has been produced -by Herbert Morris, Ltd. Loughborough. The tile which is applied truly describes it, as It is difficult to think of any movement which it cannot execute with ease owing to its unusual design.

. Marked Stability.

Having a maximum capacity of 21 tons, the Morris Versatile crane ean raise a load to a height of 20 ft. above the ground, or lower it into a truck or depression 5 ft. below ground-level. When the jib is horizontal the maximum load is 14 cwt.; when the crane hook is at a 15-ft. radius from the centre of the machine the load is 1 ton ; at 11 ft. 9 ins. radius, 11 ton ; at 10 ft. radius, 2 tons, and at 9 ft. radius, 21 tons.

A feature of great importance is that the pivot point of the jib does not move relative to the .crane chassis. Thus the stability of the machine is enhanced, and the jib does not pivot around on the chassis, owing to the special mobility of the whole crane; therefore, the weight is carried always along the longitudinal axis.

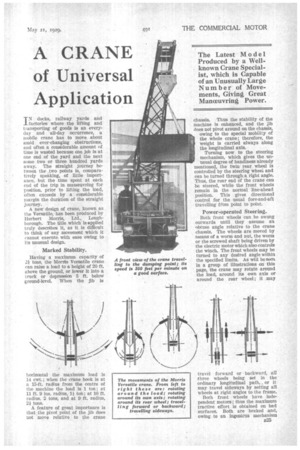

Turning now to the steering mechanism, which gives the unusual degree of handiness already mentioned, the twin rear wheel is controlled by the steering wheel and can be turned through a right angle. Thus, the rear end of the crane can be steered, while the front wheels remain in the normal line-ahead position. This gives directional control for the usual fore-and-aft travelling from point to point

Power-operated Steering.

Both front wheels can be swung outwards until they assume. an obtuse angle relative to the crane chassis. The wheels are moved by means of a worm and nut, the worm or the screwed shaft being driven by the electric motor which also controls the winch. The front wheels may be turned to any desired angle within the specified limits. As will be seen in a group of illustrations on this page, the crane may rotate around the load, around its own axis or around the rear wheel; it may

travel forward or backward, al/ three wheels being set in the ordinary longitudinal path„ or it may travel sideways by setting all wheels at right angles to the frame.

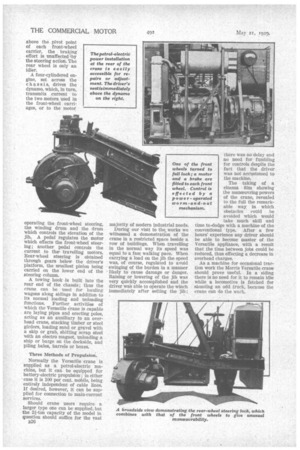

Both front wheels have independent motors; thus the maximum tractive effort is obtained on bad surfaces. Both are braked .and, owing to an algal:lens mechanism operating the front-wheel steering, the winding drum and the drum which controls the elevation of the jib. A pedal regulates the motor which effects the front-wheel steering; anotherpedal controls the current to the travelling motors. Rear-wheel steering is obtained through gears below the driver's platform, the smallest pinion being carried on the lower end of the steering column.

A towing hook is built into the rear end of the chassis ; thus the crane can be used for hauling wagons along sidings in addition to its normal loading and unloading functions. Further activities of which the Versatile crane is capable are laying pipes and erecting poles, acting as an auxiliary to an overhead crane, stacking timber or steel girders, loading sand or gravel with a skip or grab, shifting scrap steel wtith an electro magnet, unloading a ship or barge on the dockside, and piling bales, barrels or boxes.

Three Methods of Propulsion.

Normally the Versatile crane is supplied as a petrol-electric machine, but It can be equipped for battery-electric propulsion; in either case it is 100 per cent. mobile, being entirely independent of cable lines. If desired, however, it can be supplied for connection to main-current services.

Should crane users require a larger type one can be supplied, but the 21-ton capacity of the model in question should suffice for the vast B26 majority of modern hidustrial needs.

During our visit to the works we witnessed a demonstration of the crane in a restricted space beside a row of buildings. When travelling in the normal way its speed was equal to a fast walking pace. When carrying a load on the jib the speed was, of course, regulated to avoid swinging of the burden in a manner likely to cause damage or danger. Raising or lowering of the jib was very quickly accomplished and the driver was able to operate the winch immediately after setting the jib ; there was no delay and no need for fumbling for controls despite the fact that the driver was not accustomed to the machine.

The taking of a cinema film showing the manceuvring powers of the crane, revealed to the full the remarkable way. in which obstacles could be avoided which would take much skill and time to-.dodge with a machine of the conventional type. After a few hours' experience any driver should be able to become master of the Versatile appliance, with a result that the time between jobs could be reduced, thus effecting a decrease in overhead charges.

As a machine for occasional traction work the Morris Versatile crane should prove useful. In a siding there is no need for it to remain idle while a locomotive is fetched for shunting an odd truck, because the crane can do the work.