Points about Cone Clutches.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

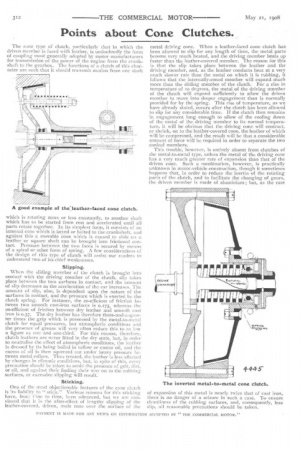

The cone type of clutch, particularly that in which the driven member is faced with leather, is undoubtedly the form of coupling most generally adopted by motor manufacturers for transmission of the power of the engine from the crankshaft to the gearbox. The functions of a clutch of this character are such that it should transmit motion from one shaft which is rotating more or less constantly, to another shaft which has to be started from rest and accelerated until all parts rotate together. In its simplest form, it consists of an internal cone which is keyed or bolted to the crankshaft, and against this a movable cone which is caused to slide on a feather or square shaft can be brought into frictional contact. Pressure between the two faces is secured by means of a spiral or other form of spring. A few considerations of the design of this type of clutch will assist our readers to anderstand two of its chief weaknesses.

I.Vhen the sliding member of the clutch is brought into oontact with the driving member of the clutch, slip takes place between the two surfaces in contact, and the amount of slip decreases as the acceleration of the car increases. The amount of slip, also, is dependent upon the nature of the surfaces in contact, and the pressure which is exerted by the clutch spring. For instance, the co-efficient of friction between two smooth cast-iron surfaces is 0.175, whereas the op-efficient of friction between dry leather and smooth cast iron is 0.57. The dry leather has therefore three-and-a-quarter times the grip which is possessed by the metal-to-metal clutch for equal pressures, hat atmospheric conditions and the presence of grease will wry often reduce this to as low a figure as one and one-third. For this reason, therefore, clutch leathers are never fitted in the dry state, but, in order to neutralise the effect of atmospheric conditions, the lea her is dressed by its being boiled in tallow or castor oil, and the excess of oil is then squeezed out under heavy pressure between metal rollers. Thus treated, the leather is less affected by changes in climatic conditions, but, in spite of this, every precaution should be taken to avoid the presence of grit, dirt, or oil, and against their finding their way on to the rubbing surfaces, or excessive slipping will result.

Sticking.

One of the most objectionable features of the cone clutch is its liability to " stick." Various reasons for this sticking have, from I'me to time, been advanced, but we are convinced that it is the after-effect of lengthy slipping of the leather-covered, driven, male cone over the surface of the metal driving cone. When a leather-faced cone clutch has been allowed to slip for any length of time, the metal parts become very much heated, and the driving member heats up faster than the leather-covered member. The reason for this is that the slip takes place between the leather and the driving member, and, as the leather conducts heat at a very much slower rate than the metal on which it is rubbing, it follows that the internally-coned member will expand much more than the sliding member of the clutch. For a rise in temperature of to degrees, the metal of the driving member of the clutch will expand sufficiently to allow the driven member to move into deeper engagement than is normally provided for by the spring. This rise of temperature, as we have already stated, occurs after the clutch has been allowed to slip for any considerable time. If the clutch then remains in engagement long enough to allow of the cooling down of the metal of the driving member to its normal temperature, it will be obvious that the driving cone will contract, or shrink, on to the leather-covered cone, the leather of which will be compressed, and the result will be that a considerable amount of force will be required in order to separate the two conical members.

This trouble, however, is entirely absent from clutches of the metal-to-metal type, unless the metal of the driving cone has a very much greater rate of expansion than that of the driven cone. Such a combination, however, is practically unknown in motor-vehicle construction, though it sometimes happens that, in order to reduce the inertia of the rotating parts of the clutch, and to facilitate the changing of gears, the driven Member is made of aluminium; but, as the rate

of expansion or this metal is nearly twice that of cast iron, there is no danger of a seizure in such a case. To ensure cleanliness of the rubbing surfaces, and, consequently, less slip, all reasonable precautions should be taken.