Bedford TM 32501 York

Page 43

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

32-ton

gross artil

by Trevor Longcroft

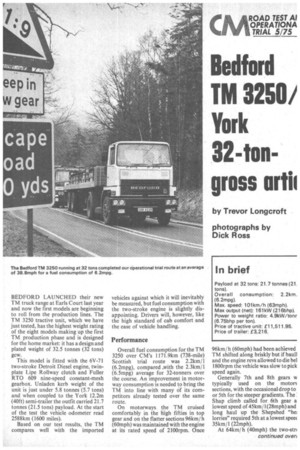

photographs by Dick Ross BEDFORD LAUNCHED their new TM truck range at Earls Court last year and now the first models are beginning to roll from the production lines. The TM 3250 tractive unit, which we have just tested, has the highest weight rating of the eight models making up the first TM production phase and is designed for the home market: it has a design and plated weight of 32.5 tonnes (32 tons) gcw.

This model is fitted with the 6V-71 two-stroke Detroit Diesel engine, twinplate Lipe Rollway clutch and Fuller RTO 609 nine-speed constant-mesh gearbox. Unladen kerb weight of the unit is just under 5.8 tonnes (5.7 tons) and when coupled to the York 12.2m (40ft) semi-trailer the outfit carried 21.7 tonnes (21.5 tons) payload. At the start of the test the vehicle odometer read 2588km (1600 miles).

Based on our test results, the TM compares well with the imported vehicles against which it will inevitably be measured, but fuel consumption with the two-stroke engine is slightly disappointing. Drivers will, however, like the high standard of cab comfort and the ease of vehicle handling.

Performance

Overall fuel consumption for the TM 3250 over CM's 1171.9km (738-mile) Scottish trial route was 2.2km/1 (6.2mpg), compared with the 2.3km/1 (6.5mpg) average for 32-tonners over the course. An improvement in motorway consumption is needed to bring the TM into line with many of its competitors already tested over the same route.

On motorways the TM cruised comfortably in the high fifties in top gear and on the flatter sections 96km/ h (60rnph) was maintained with the engine at its rated speed of 2100rpm. Once

Payload at 32 tons: 21.7 tonnes 121. tons).

Overall consumption: 2.2km, (6.2mpg).

Max. speed: 101km/h (63mph). Max output (net): 161kW (216bhp). Power to weight ratio: 4.9kW/tonr (6.75bhp per ton).

Price of tractive unit: 11,511.95. Price of trailer: £3,216.

96km/ h (60mph) had been achieved TM shifted along briskly but if baull and the engine revs allowed to die bel I800rprn the vehicle was slow to pick speed again.

Generally 7th and 8th gears w typically used on the motor's sections, with the occasional drop to or 5th for the steeper gradients. The Shap climb called for 6th gear a lowest speed of 45km/1(28mph) and long haul up the Shepshed "he lorries" required 5th at a lowest speet 35km/1 (22mph).

At 64krn/ h (40mph) the two-stn continued oven engine turned over at an economical 1300rpm along Al, and, over the undulating roads between Moffat and Dalkeith 7th gear was typically used, with infrequent selection of 8th and, for the steeper climbs, 6th.

The TM restarts on a 1 in 6 gradient in normal first without needing crawler gear so I had no qualms about the hilly A68 section. Thanks to the slick gearchange this was completed in an unfussy, almost leisurely, style. Riding Mill, which has an average 1 in 10 gradient with a short, sharp 1 in 5 section towards the summit, was climbed in slightly over 3mins 30sec with 1st gear selected for just 73.2sec and with the engine at maximum revs.

It was annoying on some of the hills, including the long Moffat and Carter Bar hauls, that the TM had to climb with the engine at full stretch in one gear because it would not pull the next higher ratio. On Carter Bat, I had to be satisfied with 4th at maximum revs because power dropped off rapidly whenever I attempted to change to 5th.

Full-pressure brake tests were completed at the MIRA proving ground during persistent rain which covered the track with a sheet of water. Considering the bad conditions, the TM returned satisfactory stopping distances from speeds of up to 64km/ h (40mph) without any hint of instability. On dry surfaces during normal driving brake performance indicated that high efficiencies could be achieved under ideal conditions.

The test vehicle was fitted with the optional Jacobs engine brake which basically converts the engine into a power absorbing compressor to provide vehicle retardation through the engine and transmission. Unlike other systems, the Jacobs brake overides the valve gear rather than restricting the flow of exhaust gas in the manifold. I could not detect any operational difference between this system and "conventional" exhaust brakes for controlling vehicle speeds on long descents. As with other systems it checked the vehicle speed on descents, needing only the odd dab on the service brake on the longer slopes.

An attractive feature of the TM which cannot fail to score with drivers is the ease of driving.

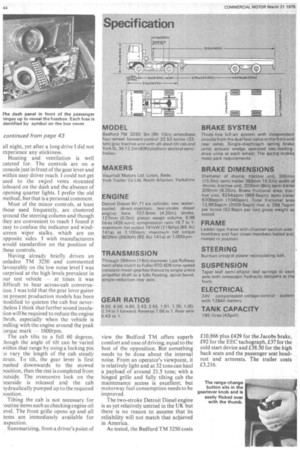

The short, stubby gearlever is conveniently close to the driver and operates in a neat, well-defined gate. Any driver should be able to make good clean changes within minutes of taking the wheel. The top eight gears, which are sufficient for all purposes except restarting on a hill, are arranged around a fourspeed gate. First gear is diagonally across from the driver and the upchange sequence is anti-clockwise around the gate until 4th gear is reached. The range-change button, which fits snugly in the top of the gear knob, is then flicked across to high with either the thumb or finger and the lever shifted into 1st / 5th position. The upchange sequence is then repeated.

The rev counter is well calibrated and -the useful engine rev band is denoted by a green sector between 1300 and 2100rpm, Ideally upward changes should be made when engine revs rise above 1800rpm and downward changes between 1300 and 1500rpm, depending on gear. The gearbox is largely foolproof, and providing the revs are about right a clean change always seems to be the result.

I found it a nuisance to have the rev counter on the left of the instrument panel and away from the driver's line of vision. It is difficult to assess engine revs accurately from the engine note and so one relies heavily on the counter and has to keep flicking glances across the cab. It would be simpler if Vauxhall swapped positions with the large glass containing gauges and warning lights which is directly in front of the driver but does not require such constant use.

The steering wheel sits relatively high compared with other 32-tonners I have driven but I quickly became accustomed to its position and used to its precise and easy action. One minor criticism is that the wide wheel spoke does obscure the speedometer when the wheel is not in the straight-ahead position.

The pedals are well positioned and I particularly liked the brake, which had good "feel" and inspired confidence, Cab comfort breaks right away from TK standards. The driver has a suspension seat as standard and both seats have a full range of adjustment. The cloth upholstery was warm to sit on after the vehicle had been standing out all night, yet after a long drive I did not experience any stickiness. Heating and ventilation is well catered for. The controls are on a console just in front of the gear lever and within easy driver reach. I could not get used to the si,vel vents mounted inboard on the dash and the absence of opening quarter lights. I prefer the old method, but that is a personal comment. Most of the minor controls, at least those used frequently, are clustered around the steering column and though they are convenient to reach I found it easy to confuse the indicator and windicreen wiper stalks, which are on apposite sides. I wish manufacturers would standardize on the position of these controls.

Having already briefly driven an unladen TM 3250 and commented Favourably on the low noise level I was surprised at the high levels prevalent in our test vehicle -• at times it was difficult to hear across-cab conversation. I was told that the gear lever gaiter an present production models has been modified to quieten the cab but nevertheless I think that further sound insulation will be required to reduce the engine throb, especially when the vehicle is pulling with the engine around the peak :orque mark I 60Orprn. The cab tilts to a full 60 degrees, :hough the angle of tilt can be varied Kithin that range by using a locking pin to vary the length of the cab steady struts. To tilt, the gear lever is first pushed downwards to the stowed Position, then the rest is completed from outside. The overcentre lock on the Pea rside is released and the cab pydraulically pumped up to the required os iti on.

Tilting the cab is not necessary for -outine items such as checking engine oil evel. The front grille opens up and all tems are immediately available for nspecti on. Summarizing, from a driver's point of

8 56, 6 56, 4 65 3 43, 2 55 91, () 74 to 1 for,%arp Reverse 7 66 to 1 5.43 .o 1. Rear axle

35, 1.00, view the Bedford TM offers superb comfort and ease of driving, equal to the best of the opposition. But something needs to be done about the internal noise. From an operator's viewpoint, it is relatively light and at 32 tons can haul a payload of around 2L5 tons; with a hinged grille and fully tilting cab the maintenance access is excellent; but motorway fuel consumption needs to be improved.

The two-stroke Detroit Diesel engine is as yet relatively untried in the UK but there is no reason to assume that its reliability will not match that achieved in America.

As tested, the Bedford TM 3250 costs

£10,866 plus £429 for the Jacobs brake, £92 for the EEC tachograph, £37 for the cold start device and £38.50 for the high back seats and the passenger seat headrest and armrests. The trailer costs £3,216.