DESIRABLE FEATURES IN THE 25-CWT. VAN.

Page 22

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

The Particular Grouping of Chassis Details which would Make a Vehicle Cheap, Reliable, and Easy to Handle.

By a Commercial Vehicle Designer,

ATYPE of commercial goods vehicle, for which a great demand was (long ago, when no such vehicle was on the market) prophesied in the columns of The Commercial Motor, is that which will deal comfortably with loads of about 20 cwt.— more rather than less. It represents a carrying capacity that brings, it closely in line with the requirements of a large body of manufacturers and traders, whilst it is just about right for rapid distribution with a small labour bill.

American makers have experienced a similar 'demand from their home markets, and realized the fact that in this country and its dominions alone there is a vast outlet for such a vehicle. British manufacturers are also now devoting attention to this particular phase of the movement, but have taken 25 cwt. as being a. more useful capacity for the type, and in this they are well advised. The ton load, with the additicns of driver and his mate or vannian and the" extras" that are bound to be added, is dealt with comfortably, and there is a, substantial .margin for overloading.

The type is destined to enjoy a very great future, and, this being the case, it might well be asked what are the best features to look for in making one's selection,jor, if one were a manufacturer, to adopt in an effort to .produce a satisfactory 25-cwt. van chassis. The objects to aim at, by both maker and user, are cheapness of production, cheapness of main: tenance and running, and ability to withstand the rough handling likely to result from the vehicle being handed over to inexperienced people. There is a further object which concerns the manufacturer, namely, suitability for overseas conditions and ability to comply. with . the . requirements of the markets in our dominions.

Passing from a consideration of the chassis as a whole, let us look at the various component parts. The selection of the .most suitable engine for such a, chassis is a. matter Where there is sure to be considerable difference of opinion. High efficiency at high speeds has become a fetish n with engine designers and, although for pleasure cars-it may be desiragle, it is very doubtful whether it is needed in an engine especially designed for a van. The

i conditions of working n commercial and pleasure motoring are so widely different that designers in

these two fields should set up different ideals at which to aim. In the writer's experience, one of the most successful engines for commercial purposes was one in which the power increased with the speed only up to a point, and then died away, owing to a • restricted .aperture of the inlet pipe. This engine gave great satisfaction, and did not put undue

strains on the transmission or on any part of the whole chassis. The designer's hand was, however, forced by his directors, and, as the outcome, the

engine was " improved " so that it showed a power curve increasing with the speed. The result was a faster engine, but a great increase in the cost of upkeep.

For a 25-cart. van a bore and stroke of 85 ram. and 120 mm. should give quite sufficient power. With re

gard to cylinder design, for commercial work there

is not much to choose between cylinders cast en bloc and those east in pairs. The one is neat in appear

ance, although more costly to renew in case of acci dent or a burst through frost. There is nothing to be gained by having a short en gine, if, to get at that result, any single part of the design is rendered less efficient or durable. A short, compact-looking engine may be good to look at, but, in laying out an engine for this par ticular purpose, the designer should look to the points to which reference will now be made.

All bearings, on the crankshaft, both throws and main bearings, should be amply long. Theories have been advanced showing that short bearings can be made to wear as well as long ones if they be large in diameter. In actual practice this does not hold good. Larger bearings have a larger peripheral speed than smaller ones, consequently the rubbing is greater and. the wear More rapid.

The writer"had an exceptional opportunity during the war of examining an enormous number of worn crankshafts of every make and class in. all stages, of

wear and dilapidation. The result of careful examination always revealed the saxtd thing' namely,

that in the case of those with.the shortest bearings otality had developed sooner than.. in :the case of those witlq longer bearings. The -centre bearing always showethmore wear than the-others, and;next to this eame'the starter 'end, which, being usually short, showed'. considerable wear. The flywheel end was always the least worn, owing to its great.length. There is littledoubt that the life of a set of bearings would be materially increased if a little more length were allowed in the centre hearing and in the starter end.

While on the subject of crankshafts, the writer feels that the results of his examination of such a large number of shafts (which may be looked upon. as an 'exceptional opportunity of gaining experience) may be of interest to engine designers. It was evident that holes drilled in the crankshafts are the cause of fractures, as in few cases were fractured shafts found in which the start of the crack had not emanated from the holes drilled for the forced-feed lubrication. Another cause of fractures was the great difference between the section of the journal portions and that of the webs. The writer is sorry

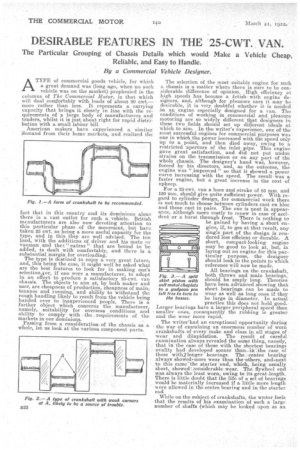

to say that the European shafts were the greatest offenders in this matter, while the American designs showed greater evenness of strength. Fig. 1 shows what the writer, from experience, considers the best form of crankshaft.

Fig. 2 is a bad example, but is not uncommon. Sharp corners should be avoided, as, even if the radius is properly proportioned, a sharp .corner at the point marked A will induce a fracture.

There iS no economy in making crankshafts of any but the highest quality of steel, as to use a lower grade is to increase the weight, not only of the crank, but of all its surroundings, which will tend to bring the cost up. A shaft of high-grade steel left black in the webs •from the forging is all that is required for commercial work.

The use of ball bearings to the main journals ef the crankshaft might be considered. Such bearings, if properly housed and arranged, and of ample proportions, will give excellent results, and, in the matter of overhauling and replacement, where skilled labour is scarce, have distinct advantages over plain bearings. The only disadvantage they seem to have is that they are slightly more noisy than lain bearings, but, in a chassis built expressly for commercial work, this is not a very serious matter.

In laying out the design of such an engine, care should be taken that the connecting rods are evenly disposed as regards bosses of both big-end and smallend. An evenly designed rod wears better in its bearings and does not have the bad effect on the crank journals that is always found when an off-set rod has been used.

The best practice of to-day is the uaeof white metal in a bronze shell, instead of die cast, for the big-end. This also applies to the main bearings, but is not considered so essential in these, Shims of the laminated type, where a number of thin plates of brass are soldered together; are strongly recommended. With this class of shim the adjustment of any bearing is made easy, even for a man of no experience. It has also the great advantage that, in taking up wear, no part of the con-. necting rod or main bearings is filed away, which is the cause of serious trouble when a new bearing has to be fitted. Another great advantage of the shim is that it affords the very best possible means of securing the halves of the bearings in their Beatings and effectually prevents movement between the bearings and -their beds. There seems Do reason whyn: aluminium pistons should not be used for such an engine, considerirg the experience maters have now had with them and the satisfaction they have given when well designed and made of the right alloy. The split skirt, as shown in Fig. 3, is recommended, as with its use a very great saving of oil can be reckoned on and smoking need never be feared. Carbon deposits are also considerably reduced by the fact of so little oil passing above the piston. Plain gudgeon pins free in both aluminium and in the small end of the connecting rod are recommended. They can be fitted with aluminium chaplets, as shown in Fig. 3. These, however, should have slightly conical ends, 'otherwise they will be continually turning round in their holes and will wear lose. This class of gudgeon is the easiest to renew, especially by unskilled persons.

As to whether the cylinders should have a loose head or not is an open question. For general usage, the Axed head might be considered the simpler to handle by inexperienced persons. With the loose head, should anything happen to the gasket, and a new one not be handy, there is likely to he trouble.

In the case of valves,' again we are faced with a question which is not easy to decide. The overhead valve has certain advantages in some instances, but, for rough work in out-of-the-way places and with unskilful handling, the writer would be inclined to recommend the ordinary arrangement of valves. Where a world's trade is expected, lorries should be made so that they can operate over the most uneven ground without causing any undue strains to any part. It is most essential that the engine should be hung in such a manner that no twisting can come .on the crankcase owing to unevenness of the ground. A good scheme of three-point suspension is, there. fore, absolutely necessary.

If Colonial conditions are to be studied, a radiator of ample dimensions should be fitted, and care should be taken that it is of a type which is highly efficient for its weight. The straight tube type, with detachable headers top and bottom., has been :proved to be the most suitable for lorry and van work in all sorts of districts where water containing much solid matter in solution is likely to be found.

As there is no knowing in what climate a vehicle may be required to work, it might be well to con eider the adoption cu f the device shown in Fig. 4, where one flange of the fan pulley is adjustable, so that with a V belt the speed of the fan could be varied for extremes of climate, the normal position being as shown, which would allow a variation for colder or hotter climates.

Pumps or hustlers are a source of trouble, as the bearing of the spindle must contain some sort of gland, which requires attention at times. Considering the excellent results obtained from thermo-siphon cooling, when properly carried out, it is hard to see the necessity for either pump or hustler, and in this regard I am in disagreement with " The Skotch," -whose otherwise excellent specification appeared in a recent contribution under the heading Help for Hauliers." The keynote of the carburetter chosen should he economy of petrol. Variations in climate and altitude should, of course, be allowed for. A hot-air muff over the exhaust pipe is preferable to water. heating, as it gets hot sooner. It should be fitted with some device whereby it can be regulated and thrown out of action altogether in hot climates. Some means of regulating extra air is advisable, as, in the hands of a careful driver, petrol can be saved by the use of such a device.

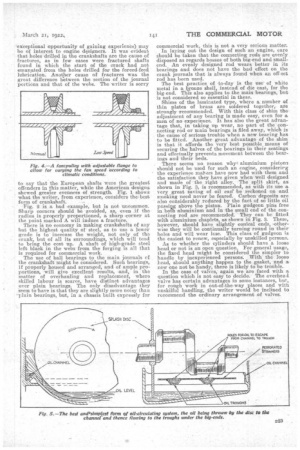

With the use of pistons which have the skirt split, as shown in Fig. 3, the exact degree of lubrication is no longer a matter of great importance,; therefore, a simpler and cheaper system of circulation of oil can be adopted. That -shown in Fig. 5 is probably the very simplest., and, at the same -time, about the most reliable known. In this system a disc is attached to the crankshaft, dipping into a sump, so that it sends a continuous flow of oil in the direction shown. This flow is caught by a channel cast integral with the crankcase, which leads it to the

troughs. Any oil overflowing, splashed about, .gravitates down 0,16 walls of case and finds its way to the sump again, first having to pass through the strainers which cover the entire space between the troughs as shown. This system has, however, one disadvantage, and that is there is no indication lo the driver that the oil is circulating or that there is any oil in the case. As regards the absence of indication of circulation, the system is so simple that no indication is needed.

The practice of fitting only one universal joint between the engine and gearbox.: is not mechanically 13:14

correct, and puts an unfair strain on the joint which it is not constructed to withstand.

Should errors occur as shown in Fig. 6, one joint will do all that is required, but should the frame spring so that there is an error as shown in Fig. 7, one joint cannot possibly deal with it, and two joints and a short intermediate shaft are needed, as shown in Fie.. 8.

The flexible joint composed of leather or other pliable material is undoubtedly the most suitable cue for the purpose we have under consideration, as it requires no attention or lubrication, and is absolutely silent. If a clutch can be arranged so that no sliding motion is necessary in the shaft, so much the better, as all sliding means wear and rattle. The choice of universal joints behind the gearbox depends largely upon the type of transmission adopted. Should there be no torque tube fitted, flexible or rag joints are undoubtedly the best, and if of ample proportions, will give no trouble. Even when the torque is entirely taken on the springs, these joints will be found to answer well.

Dealing now with the gearbox, three speeds should be sufficient for a vehicle of the capacity under consideration. The simplest form of sliding gear with coarse-pitch teeth of fairly ample length, should be the most suitable. The shafts should be of large diameter to prevnt spring. The sliding parts should be as light as possible compatible with strength. Inserted keys arc preferable to splined shafts, and ball bearings should be used throughout, on account of easy removal. The spigot should receive more attention than is bestowed in many cases, and should be well up to its work. Central change levers and gate certainly simplify the removal of the gearbox for repairs, -etc., and make for a neat and clean design. Here, aanain, three-point suspension is most essential.

The single dry-plate clutch is recommended as being the most suitable, as it needs practically no attention and should not require the shaft leading from it to the gearbox to slide endways. With a view to keeping all unsprung parts as light as possible, forged axles arc recommended. The strength should not be reduced suddenly at any point for the purpose of forming shoulders, but an even strength kept up, so as to reduce the liability to fracture. Worm drive would seem to be the most suitable final reduction, about 6 to I being what has been found best for such weights. Sleeve-borne wheels, fitted with taper roller bearings, are recommended.

There are still many differences of opinion as to the mounting of back axles for light lorry work, but, the writer gives it as his opinion that the most suitable method for the purpose under consideration is the construction where the whole of the torque is taken on the springs and where there are two universal joints between the wormshaft and the gearbox. Before the introduction of the rag joint there was au idea that the fewer universal joints the less there would be for the driver to look after. This, however, does not apply to rag joints, as they want no attention, and, if well proportioned and fitted, should give no trouble.

There are many points in the design of the steering head which call for care in design. In many steering heads the bearings of the pivot pin are too close together. This throws a very severe pressure on the bearing surfaces and • indubes rapid wear. The centres of the steering head should he as near to the wheel as possible. If disc wheelsare used, there should be no difficulty in getting the line through the head to cut the point of contact with the ground. At the last Show it was noticeable that, in some cases where. disc wheels were fitted this point had been altogether neglected. All steering rods and coupling rods should be behind the axle, so as to be protected from damage. The steering box should be of the type where a complete worm wheel is used—not a sector—and should have a taper square at the end where the steering arm is fitted. The life of this arrangement is four times as long as with a sector. As Colonial work; inav be done, it is advisaMe that the clearance from -the ground be. kept as high as possible. A good angle on the steering post gives. a smart look to a design, but, if carried far enough, the steering box is greatly in,.the way'of the engine, therefore a moderate angle is recommended.

The matter of the position of the foot brake is still an open question. The writer is inclined to think that there fs more risk of failure through having both brakes on the back **heels, as the failure of• one through breakage of soibe part is likely to cause the failure of the. second brake. Brake drums should he of pressed steel, they are then cheap to produce and renew.

The clutch withdrawal mechanism should be either in a separate box protected from dirt or embodied, in the gearbox. The wheels should be either cast or, if of disc pattern, should he so constructed that they will not buckle.out of truth should they skid against a kerb. Shackle joints. shouldbe lubricated by means of oil—not grease. Petrol feed should be by. gravity and the filler should be outside the body, so that no petrol is spilt about the seat While. filling up. The levers for change speed and brakes, and the pedals could be light steel pressings. A drive fer the magneto should be provided on the engine, and there should be another on the gearbox for the mileometer.