18 fror 6-to Bedford Diler

Page 40

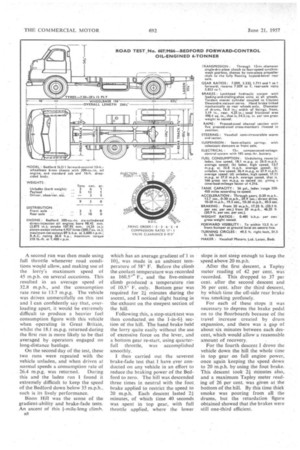

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

MU C H interest has been aroused by the new Bedford 300-cu.-in. oil engine since its

introduction last' February. This unit, which is offered in Bedford 4-, 5and 6-ton chassis, has been tested in a long-wheelbase forward-control 6-ton lorry and its performance shows -it to be as successful as had originally been hoped by operators.

The engine gives fast acceleration and a good hill-climbing performance, whilst its fuel-consumption rate when running at the British legal speed is extremely economical and shows a 60-per-cent. improvement over the 6-tonnet powered by the 214-cu.-in, petrol engine which was tested in February.

Heavy-duty Model The vehicle submitted for test was the heavy-duty 6-tonner with a.10-in. deep chassis frame, which, in common with the front and rent

\ axles, brakes and springs, is as used on Big Bedford 7-ton models. It

was not tested with a full payload of 6 tons, primarily to keep the gross weight down to 9 tons 3 cwt., which was the weight at which the petrolengined model was tested. A 6-ton payload can be carried with perfect safety, however, as the chassis strength gives a, large margin 'of

reserved strength. , . A net power output of 89 b.h.p., :developed at 2,600 r.p.m., is given by the Bedford engine. Dry, slip-fit cylinder liners are used and steelbacked copper-lead main and big-end bearings are fitted. The sevenbearing crankshaft carries a torsional viscous silicone fluid Vibration damper. Each piston carries five rings, the top compression..ring being chromium plated.

B6 The Chromidium cast-iron cylinder head hat separate inlet and exhaust ports, the manifolds being at oppo . site sides of the head. Two-piece exhaust valves with austenitic steel heads, fitted with free-release rotators, are used. The camshaft and auxiliary drives are by helical gears at the front end of the engine.

A C.A.V. fuel-injection pump With vacuum governor is employed and the four-hole-nozzle injectors are located in the cylinder head at an angle of 20 The timing case is designed to accommodate a hydraulic pump, to be driven off the camshaft gear, for use in conjunction with power-assisted steering gear.

Three-point engine mounting is employed with a single slab mounting unit at the front of the crankcase, below the timing gears, and a. sheartype rubber mounting at each side of the clutch housing. This mounting system combines with the crankshaft vibration damper to giVe smooth running throughout the whole speed range of the engine, and this is particularly noticeable when idling.

Complete with 16-ft. drop-sided body, the 13-ft. wheelbase 6-ton oiler has a dry taxation weight of approximately 3 tons 2 cwt., and, as tested, its kerb weight was 3 tons 6+ cwt. Complete with a' load of concrete blocks, plus driver and passenger, the 'lorry was tested at 9 tons 3 cwt. A weight distribution check showed reasonably good inter-axle loadings: The test vehicle had a 5.833 to 1 ratio rear axle, there being alternative ratios of 6.8 and 5,286 to 1. An Eaton two-speed axle is offered as optional equipment.

For the first tests, the Bedford was

taken on to the A6 road between Harpenden and Luton and here braking arid, acceleratiod trials were

conducted. As 'might be expected with a frictional area giving 54.5 sq.

• in per ton gross weight as tested, the 'brakes are extremely effective, and when making emergency, stops from 30 m.p.h. all . the wheels locked instantly, which resulted in the stopping distances being exaggerated by skidding.

The tests from 20 m.p.h. did not cause excessive skidding and the maximum deceleration rates shown by the Tapley meter were nearly the same as the average deceleration rates shown by the stopping distances, indicating negligible servo lag.

Reinforcement Advisable

So efficient is the foot brake, in fact, that operators would be well advised to have reinforced headboards, that of the test vehicle being bowed appreciably by the test load.

When applied from 20 m.p.h., the hand brake gave repeated Tapley meter readings averaging 44.5 per cent., showing exceptional efficiency for a vehicle of thiS size. The brake pedal is not heavy to operate under normal conditions and the long travel gives adequate sensitivity to avoid . over-heavy , braking when running unladen.

For the standing-start acceleration tests. the lorry was started off in second gear and the figures obtained up to 30 m.p.h. were only a little slower than those recorded with the petrol-engined model, whilst up to 20 m.p.h. the oiler is faster. Consistent direct-drive acceleration rates were obtained between 1.0 m.p.h. and 30 m.p.h., and during this test the engine showed smoothness when under full load at 10 m.p.h..

Two laden fuel-consumption tests

were made, using an undulating sixmile course between Barton and Clophill. These tests took place in an ambient temperature of 58.5° F. with the radiator coolant at 162° F., and a considerable amount of traffic' was encountered during the runs, neeegsitating . frequent use of the indirect ratios.

For the first test, the vehicle was driven at between 30 and 35 m.p.h. to simulate the speed of a vehicle driven at the legal limit. The course was completed at an aver-age speed of 26 m.p.h. and the total fuel used indicated a consumption rate of 18.1 m.p.g., which is an exceedingly economical figure. During thisr run third gear was used twice for a total time of one minute.

A second run was then made using full throttle whenever road conchtions would allow, and, making use of the lorry's maximum speed ot 45 m.p.h. on several occasions. This resulted in an average speed of 32.8 m.p.h., and the consumption rate rose to 13.7 m.p.g. The vehicle was driven unmercifully on this test and I can confidently say that, overloading apart, it would be extremely difficult to produce a heavier fuel Consumption figure with this vehicle when operating in Great • Britain, whilst the 18.1 m.p.g. returned during the first run is more likely to be that averaged by operators engaged on long-distance haulage.

On the second day of the test, these two runs were repeated with the vehicle unladen, and when driven at normal speeds a consumption rate of 26.4 m.p.g. was returned. During this and the laden run I found it extremely difficult to keep the speed of the Bedford down below 35 m.p.h., such is its lively performance.

Bison Hill was the scene of the gradient-ability and brake-fade tests. An ascent of this 1-mile-long climb, n8

which has an average gradient of 1 in 101, was made in an ambient temperature of 58° F. Before the climb the coolant temperature was recorded as 160.5° F., and the five-minute climb produced -a temperature rise of 10.5° F. only. Bottom gear was required for 2+ minutes during the ascent, and I noticed slight hazing in the exhaust on the steepest section of the hill.

Following this, a stop-start test was then conducted, on the 1-in-61 section of the hill. The hand brake held the lorry quite easily without the use of excessive force on the lever, and a bottom gear re-start, using quarterfull throttle, was accomplished smoothly.

I then carried out the severest brake-fade test that I have ever conducted on any vehicle in an effort to reduce the braking power of the Bedford to zero. The hill was descended three times in neutral with the foot, brake applied to restrict the speed. to 20 m.p.h. Each descent lasted 2+ minutes, of which time 40 seconds was spent in top gear, with full throttle applied, where the lower

slope is not steep enough to keep the speed above 20 m.p.h.

After the first descent, a Tapley meter reading of 42 per cent. was recorded. This dropped to 37 per cent. after the second descent and 36 per cent. after the third descent, by which time the off-side rear brake was smoking profusely.

For each of these Stops it was necessary to depress the brake pedal on to the floorboards because of the travel increase created by drum expansion, and there was a gap of about six minutes between each des. cent, which would allow a reasonable amount of recovery.

For the fourth descent I drove the vehicle down the hill the whole time in top gear on full engine power, once again keeping the speed down to 20 m.p.h. by using the foot brake. This descent took 2+ minutes also, and a maximum Tapley meter reading of 26 per cent. was given at the bottom of the hill. By this time thick smoke was pouring from all the drums, but the retardation figure obtained showed that the brakes were still one-third efficient. Within five minutes of this final test the braking efficiency had recovered to 55 per cent. when stopping from 20 m.p.h., showing a reasonably safe fade-recovery rate.

The fact that the brake pedal could be depressed to the floorboard after each of these tests was slightly disconcerting, but Mr. John Alden, the Bedford commercial vehicle engineer, explained that this somewhat long pedal travel was a result of providing an overall leverage ratio which gave a reasonably safe standard of braking if for any reason the servo became inoperative. Without servo, 35 per cent. efficiency at 200 lb. pedal pressure can be obtained.

The leverage involved results in a considerable increase in pedal travel m relation to drum expansion. Furthermore, the pedal travel would be exaggerated by slight compression of the woven brake facings fitted because of the high operating temperatures. Moulded facings would help to effect a cure.

Stringent Test In my opinion the mechanical advantage given by the brake linkage. could be reduced without appreciably detracting from the "without servo" :braking performance, bat giving a greater reserve to cope with drum expansion on long hills. Nevertheless, the test I carried out on the Bedford would be equivalent to descending a hill of at least six miles Length with an average gradient °I 1 in 10 in the normal manner, i.e., with braking assistance from the engine, and I find it difficult to believe that under normal operating conditions the degree of fade obtained could ever be repeated.

The Bedford handles well on the road, although the suspension is a little on the hard side both when running laden and unladen. This would be because 7-tonner springs are used at the front axle and 7-tonner springs less the helper Leaves are used at the rear axle. Dampers are 'fitted as standard equipment at the front axle, however, and these help to create a fairly smooth ride in the cab.

The semi-irreversible steering creates very little castor action when running laden and none at all when running unladen, and at high speeds in the unladen condition this lack of castor action creates a tendency to wander which is not, however, hard to correct. This effect should wear off in time.

A 20-in, wheel is fitted to this 6q tanner, as opposed to the 174 in. diameter wheel employed on the ot:her

6-tonners, and as a matter of personal preference I found the smaller wheel more manageable. The 20-in. wheel should not rea4 be necessary with a front axle loading of under 31 tons.

I was particularly pleased to find that the engine noise never became excessive during my test, even when running on the governor. At 30 m.p.h. in top gear, conversation in normal tones is possible inside the cab, and a further commendable feature is the quietness of the unit when on the over-run.

• Room for Three

The cab of the test vehicle was fitted with a two-man passenger seat, this being optional equipment, and when carrying a photographer in addition to the driver there was plenty of room on the dual seat. A padded rest is provided for the right shoulder of the inner passenger to prevent him from sliding sideways, and there is ample foot room for two people.

After the road-work section of the test I was able to conduct a brief series of maintenance tasks on the chassis. I was somewhat disappointed with the engine accessibility given; such items as the air cleaner and batteries are not particularly well placed to encourage frequent attention.

Access to the radiator filler cap is given by a flap beneath the windscreens. This flap can be lifted in three seconds and it took me a further 16 seconds to verify the water level. I then spent 64 minutes checking the air cleaner level. The cleaner is difficult to reach and the cast-aluminium cover is retained by two bolts, a wing nut and a hose clip, none of which is easy to loosen because of the almost inaccessible location of the cleaner.

Oil Checking Easy A small trap in the right-hand side of the engine cowl gives access to the engine oil dipstick, and I was able to check this level in half a minute, being particularly gratified to find that the dipstick orifice in the crankcase has a wide mouth.

A small combined filler and level plug is provided in the rear face of the gearbox, and by removing this I was able to check the gearbox oil level in three-quarters of a minute, at the same time noting that topping up would not be particularly easy and would necessitate the use of a gun or syringe.

No difficulty was experienced in checking the rear-axle oil level through the combined filler and level hole in the rear casing. The brakefluid reservoir is combined with the master cylinder, which is mounted on the servo motor on the off-side frame member immediately behind the cab. Checking the fluid level inside this reservoir took a matter of 30 seconds.

There is a 6v, battery beneath Mei driving and the passenger seats and it took me 6 minutes to check the electrolyte levels in these two batteries. The seat cushions have to he removed and then there is a small panel, secured by two bzus fasteners, to be removed from each seat pan. The driver's seat cushion is not difficult to remove or replace, but the passengers' seat cushion, which is mounted on slides so that it can be hinged up, is rather difficult tp re-locate.

It took me only 12 seconds completely to rtmove the engine cowl, and I then spent four minutes in removing No. 6 injector, the principal difficulty being the lack of proper spanners to fit the injector clamp nuts. I replaced this injector in 3,1. minutes and then turned my attention to the main fuel filter, which is positioned low down to the rear of the left side of the cylinder block, and thus below the cab floor level.

Awkward Task

Working from above, I managed

to remove the securing bolt and loosen the filter bowl in If minutes, but I then had to let the bowl drop to the ground because it was impossible to withdraw it upwards between the .engine and the cab floor. Removal of the fuel-filter element should certainly not be a two-man job.

Unlike the lighter 6-ton chassis, Which have rear mounted spare wheels, the 13-ft.-wheelbase vehicle has an amidships spare-wheel carrier in common with the 7-ton chassis. The wheel is secured by three bolts, the heads of which fit the wheelbrace, and I was able to remove the wheel in 3 minutes and replace it in 31 minutes.

I did not have time to carry out brake adjustments but from previous experience of Bedfords I can state that there should be no difficulty in carrying out this job, it being possible to actuate the large internal adjusters by hand.

As tested, complete with 16-ft. drop-sided body, the vehicle has a basic price of £1,192, and in addition to this figure is £236 3s. 3d. purchase tax. The 13-ft. wheelbase chassis is not available for export.