Mobile Refuelling Equipment for Aircraft

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

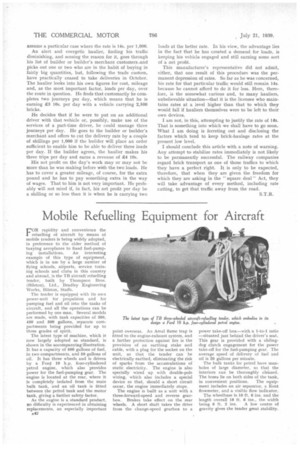

FOR rapidity and convenience the refuelling of aircraft by means of mobile tenders is being widely adopted, in preference to the older method of taxying aeroplanes to fixed fuel-pumping installations. An interesting example of this type of equipment, which is in use by a large number of flying schools, airports, service training schools and clubs in this country and abroad, is the TB aircraft ref tender, built by Thompson Bros. (Bilston), Ltd., Bradley Engineering Works, Bilston, Staffs.

The tender is equipped with its own power-unit for propulsion and for pumping fuel and oil into the tanks of aircraft, and all the operations can be performed by one man. Several models are made, with tank capacities of 350, 450 and 500 gallons, separate compartments being provided for up to three grades of spirit.

The latest type of machine, which is now largely adopted as standard, is shown in the accompanying illustration. It has a capacity of 500 gallons of fuel, in two compartments, and 50 gallons of oil. It has three wheels and is driven by a Ford 10 h.p. four-cylindered petrol engine, which also provides power for the fuel-pumping gear. The engine is located at the rear, where it is completely isolated from the main bulk tank, and an oil tank is fitted between the petrol tank and the motor tank, giving a further safety factor.

As the engine is a standard product, no difficulty is experienced in obtaining replacements, an especially important point overseas. An Amal flame trap is fitted to the engine-exhaust system, and a further protection against fire is the provision of an earthing stake and cable, with a plug for the socket on the unit, so that the tender can be electrically earthed, eliminating the risk of sparks from the accumulations of static electricity. The engine is also specially wired up with double-pole wiring, which also includes a special device so that, should a short circuit occur, the engine immediately stops.

The engine is built as a unit with a three-forward-speed and reverse gearbox. Brakes take effect on the rear wheels. A short shaft takes the drive from the change-speed gearbox to a power take-off box—with a 1-to-1 ratio —situated just behind the driver's seat. This gear is provided with a slidingdog clutch engagement for the power take-off for the fuel-pumping gear. The average speed of delivery of fuel and oil is 20 gallons per minute.

The hulk tanks for petrol have manholes of large diameter, so that the interiors can be thoroughly cleaned. The hoses lie on both sides of the tank,

in convenient positions. The equipment includes an air separator, a Kent llowmeter, and a visible flow indicator, The wheelbase is 10 ft. 6 ins, and the length overall 16 ft. 6 ins., the width

being 6 ft. 2 ins. A low centre of gravity gives the tender great stability.