When you are on a windswept production platform in the

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

North Sea you want to be sure that the necessary equipment and support is on hand. CM paid a visit to Aberdeen-based Ashley Industries—a firm whose work includes transporting vital gear for the offshore oil industry day in, day out.

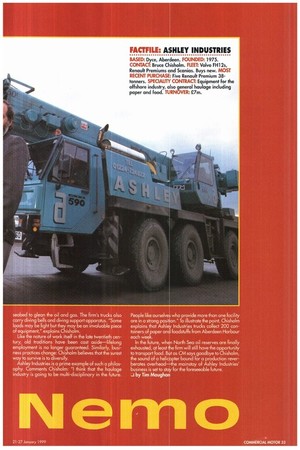

The temperature is just above freezing when CM arrives at the Ashley Industries headquarters at Dyce, Aberdeen. Metres away from its perimeter fence is the city's airport—passenger jets scream from the runway into the sky. But more striking is the seemingly endless stream of large helicopters, hovering wasp-like above the airstrip.

In this area a chopper is more than a form of luxury transport for high fliers. It is a crucial piece of kit in ferrying men and materials to and from North Sea oil rigs and production platforms. The Sea Kings thundering above the Ashley Industries depot are a noisy reminder of where much of Aberdeen's wealth was derived: from the extraction of oil and gas hundreds of feet below the sea. And such marine work requires a colossal amount of equipment—trucks included.

Specialising

In 1975 the Ashley Group was founded in Aberdeen. Specialising in painting and shotblasting, the firm originally invested in a single truck to transport equipment to the work site. Within five years the company was running 15 tractive units, and by the late eighties that had increased to 40. The expansion warranted the creation of Ashley Industries—the transport wing of the Ashley Group. Today Ashley Industries operates 70 commercial vehicles, from vans to heavy haulage units. But the firm is not only concerned with road transport, as Bruce Chisholm, finance director, explains: "We also have 20 cranes, from 20 tonnes to 120 tonnes," he says. Chisholm says the firm has to be ready to serve the lucrative oil industry—not just in terms of transport. 'We offer a package of cranes, storage and transport. The group has always been the leader in the supply of support packages for the offshore industry." That method of working was made clear earlier this month when the company took delivery of a mammoth German-manufactured 96-tonne crane. With a 1,000-tonne lifting capacity, the crane will be used to transfer pipes for the offshore oil and gas industry from truck to ship at Aberdeen Harbour. Here, Ashley Industries will use its fleet of flatbeds and low-loaders to ensure the pipes get to their underwater location.

Still, if is heavy haulage which ultimately gets the equipment from A to B—and Ashley Industries has invested heavily in the vehicles and support which make it all possible. The firm recently bought five Renault Premium 385.15s, and in

1991 a state-of-the-art 800m2 service facility was opened at the Dyce site, at a cost of £300,000. CM takes a look. Chisholm says: "We have six fitters here. The custom-built facility means we can control costs better, and it means that we can have 24hour servicing. It's money well spent."

Back to the finance director's office. The room is crammed with scale models of Jaguar cars, and the walls are adorned with pictures of WVV2 Lancaster bombers and Spitfire fighters. "I have been collecting the models for 15 years," says Chisholm, adding: "I have always been interested in motoring and engines, so I thought this job would be ideal.

"In this job no two days are the same. There is always a different problem presenting itself—that is part of the challenge." Chisholm describes the nature of the company's transport consignments—loads which could be described as a little unconventional. "Our lorries carry aviation fuel tanks—we pick them up from the suppliers, then we take them to the harbour at Aberdeen. They are then transferred on to ships and taken to the production platforms and oil rigs." Ashley Industries' low-loaders prove their worth when ferrying drilling gear to the harbour. Consignments include the 2500,000 "Christmas Tree" drill—a highly intricate piece of equipment and one which is essential to work on North Sea platforms. After all, it is literally at the cutting edge of the industry, cutting deep into the seabed to glean the oil and gas. The firm's trucks also carry diving bells and diving support apparatus. "Some loads may be light but they may be an invaluable piece of equipment," explains Chisholm. Like the nature of work itself in the late twentieth century, old traditions have been cast aside—lifelong employment is no longer guaranteed. Similarly, business practices change: Chisholm believes that the surest way to survive is to diversify, Ashley Industries is a prime example of such a philosophy. Comments Chisholm: "I think that the haulage industry is going to be multi-disciplinary in the future. People like ourselve who provide more than one facility are in a strong posi on." To illustrate the point, Chisholm

explains that Ashl Industries trucks collect 200 containersof paper an foodstuffs from Aberdeen Harbour each week.

In the future, when North Sea oil reserves are finally exhausted, at least te firm will still have the opportunity to transport food. B4it as CM says goodbye to Chisholm, the sound of a helic ter bound for a production rever berates overhead e mainstay of Ashley Industries' business is set to stay for the foreseeable future. -1 by Tim Maughan