EARLY START

Page 33

Page 34

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

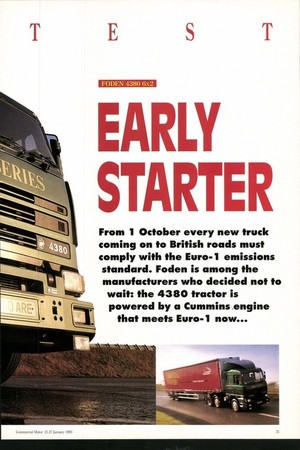

From 1 October every new truck coming on to British roads must comply with the Euro-1 emissions standard. Foden is among the manufacturers who decided not to wait: the 4380 tractor is powered by a Cummins .engine that meets Euro-1 now...

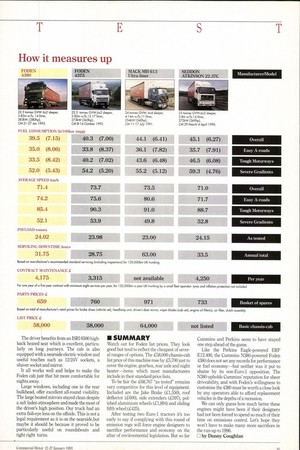

Price as tested: £68,767 (ex-VAT). Includes Jacob's engine brake, air deflector kit, polished alloy wheels, Eberspacher D1 L C night heater and Jost sliding fifth wheel.

Engine: 14 litres, 283kW (380hp). GCW: 38 tonnes.

Payload: 24.02 tonnes. Speed: 71.4km/h (44.4mph).

Fuel consumption: 39.5 lit/100km (7.15mpg).

Time was when trucks were designed by engineers for efficiency. These days they seem to be designed by politicians for the environment. The latest example of this process is the spate of "new" vehicles coming on to the market with engines that meet the EC's Euro-1 emission standard which comes into force on 1 October.

Engine designers have generally been able to meet Euro-1 without too many changes— the wholesale adoption of electronics has been avoided, much to the relief of some workshop managers—but most engines have become more complex and less efficient.

By the time Euro-2 arrives, around 1996, designers may well be forced to adopt computerised engine management and all that entails.

In the meantime Cummins is at the forefront of engine emissions control, driven by the need to keep up with US as well as EC legislators. Cummins has its CELECT computer management system, but in the bread-andbutter world of fleet sales it has managed to keep its new 14-litre straight-six N380 mercifully free of such complication.

That must come as good news to Foden and the rest, who can well do without the added cost of training and spare parts which seems to accompany every new product line. The N380 has generated only a handful of new part numbers.

PRODUCT PROFILE The chassis featured here is not far removed from the Perkins Tx-powered Railfreightowned twinsteer exclusively tested by Commercial Motor last year (CM 8-14 Oct). That Foden was the air-suspended model with ECAS electronic height control launched at TipCon —this one has the original twinsteer suspension: semi-elliptic steel springing on the drive axle with supplementary air suspension on the second steer. This set-up combines the simplicity of steel with the traction advantages associated with dumping air. Hydraulics is the only alternative.

The Railfreight truck was designated 4375; this 4380 has a nearly identical power output and their torque outputs are pretty close too so we have included the 4375 in our comparison tables. The air-to-air charge-cooled N380 replaces the air-to-water E365 in most ranges, Foden and Seddon Atkinson included.

Peak power, as the designation implies, is 283kW (380hp); developed at 1,900rpm. Peak torque of 1,728Nm (1,2751bft) is delivered at 1,200rpm and and the effective driving range is 1,200-1,700rpm. The specific fuel consumption curve - a measure of fuel economy relative to engine speed at full load - dips to its lowest point at 1,550rpm.

The N380 features Cummins' mechanical stepped timing control system (STC). This works in conjunction with higher injection pressures within the PT (pressure timed) injection mechanism to reduce emissions and maximise fuel economy under varying loads and ambient temperatures. STC is fully automatic, though the driver often hears it at work, especially when moving the accelerator pedal under light loads.

Foden has specified the lower of two torque ratings for the N380; Cummins also produces the N380HT (High Torque) which is mechanically identical but delivers 4% more torque at the same peak output speed of 1,200rpm. It also develops around 4% more power across the working speed range, with no change to peak power at 1,900rpm.

Both versions are built at Shotts; they are a spin-off from a recent tender for a large contract. Few, if any, vehicle manufacturers are expected to offer both versions as they are so similar.

Our test vehicle came with an optional factoryfitted Jacob's engine brake. For a 35kg weight penalty and £1,550 you get much more engine retardation than a conventional exhaust brake.

The Jake Brake fits between rocker cover and cylinder head. It does not interfere with the normal operation of the engine and maintenance is hardly affected: the only real drawback is the noise it generates.

• PRODUCTIVITY Cummins claims improved fuel economy and cleaner emissions for its new engine. The former won't be difficult to achieve, given the poor results we achieved with the Super E365 in a Seddon Atkinson Strato (CM 29 March - 4 April 1990). Those results are also contained in our comparison table.

This time round fuel economy was fair at 39.51it/100km (7.15mpg), but given the near perfect conditions with following winds on all three days, we were looking for something well above 72mpg. Only a week before that was the figure achieved by the higher powered Euro-1 Perkins Eagle Tx400 fitted in an ERF running into heavy rain and crosswinds for more than half the test.

Next to the Tx375-powered Railfreight Foden the N380 did rather better. Overall fuel economy has improved ; it also did better on the final day's motorway and gradient sections.

The Railfreight truck was more efficient at 80km/h (50mph), but that could simply be a matter of gearing. Against the field the N380 did best on motorways and on the hills. Its journey times were well up to standard, slowed only by the vagaries of British traffic.

• ON THE ROAD For sheer driveability the N380 is in a class of its own. The sound is pure Cummins, as is the highrevs route to best economy. The speed limiter can be counted on to take the edge off the 14-litre engine's keen acceleration on the motorways but Foden's optional speed-hold switch can also be depressed by the driver at any time to stay at any road speed below 60mph.

So much for the Go; what of the Stop? The Jake Brake certainly reduced journey times by allowing us to descend hills quickly and safely. It may be more complex than your average exhaust brake, but in driving terms it offers the same benefit of holding a constant road speed in a higher. gear, making for quicker journeys with the service brakes held in reserve, fresh and ready for action.

The standard exhaust brake floor valve is replaced by two unlit dashboard switches. The first is a simple on/off toggle; the Jake should only be used once the engine has warmed up. The second is a three-position control which activates the brake on two, four or all six engine cylinders to fine tune the retardation on motorways and slower, undulating drops.

Microswitches on the clutch and throttle pedals prevent misuse and the risk of stalling the engine.

Used correctly the Jake avoids the need for the vast majority of service brake applications. This implies a significant reduction in lining wear, but it needs a competent driver if payback is to be achieved.

The big Foden cab is well suspended and, along with the driver's air seat, makes up for any imperfections in the suspension. That said, there were few to speak of. Steering is a touch vague, as we have noted in previous Foden tests (Railfreight included) but there was no sign of the second axle bounce sometimes experienced when braking over rough ground.

That may have something to do with the fact that at 15.32 tonnes the tractor's rear bogie was loaded close to the maximum, almost 1.5 tonnes heavier than on the Railfreight truck.

A clear bonus in our book was the way the twin-steer's brakes and steering worked so well together, especially when braking in the bends on our gradients section. We punch on during this section, pushing the truck hard to maintain speed and economy. The result, on a road well known to our road testing team, is the frequent hard use of brakes and steering together. This soon unmasks hidden quirks in the chassis/suspension/ brakes set up—but in this case there were none.

• CAB COMFORT Foden's GRP Hi-Line cab is a large and well appointed design.

The past 18 months have brought a number of updates including the introduction of the Hi-Line high-roof cab as standard on all 4000 Series tractor and heavy drawbar models.

A new front grille, marque and model badging were launched at last year's TipCon. The interior is furnished in a new, brighter trim on the seats and bunk, and there's a clearer instrument panel with improved backlighting. For our money the driving layout is one of the best in the business The driver benefits from an ISRI 6500 highback heated seat which is excellent, particularly on long journeys. The cab is also equipped with a nearside electric window and useful touches such as 12/24V sockets, a shaver socket and mirror.

It all works well and helps to make the Foden cab just that bit more comfortable for nights away.

Large windows, including one in the rear bulkhead, offer excellent all-round visibility. The large heated mirrors stayed clean despite a salt laden atmosphere and made the most of the driver's high position. Our truck had an extra fish-eye lens on the offside. This is not a legal requirement as it is on the nearside,but maybe it should be because it proved to be particularly useful on roundabouts and tight right turns.

• SUMMARY Watch out for Foden list prices. They look good but tend to reflect the cheapest of several ranges of options. The £58,000 chassis-cab list price of this machine rose by £5,700 just to cover the engine, gearbox, rear axle and night heater-items which most manufacturers include in their standard price lists.

To be fair the £68,767 "as tested" remains very competitive for this level of equipment. Included are the Jake Brake (£1,550), roof deflector (£600), side extenders (£597), polished aluminium wheels (£1,894) and sliding fifth wheel (£425).

After testing two Euro-1 tractors it's too early to say if complying with this round of emission regs will force engine designers to sacrifice performance and economy on the altar of environmental legislation. But so far Cummins and Perkins seem to have stayed one step ahead of the game.

Like the Perkins Eagle-powered ERF E12.400, the Cummins N380-powered Foden 4380 does not set any records for performance or fuel economy-but neither was it put to shame by its non-Euro-1 opposition. The N380 upholds Cummins' reputation for sheer driveability, and with Foden's willingness to customise the 4380 must be worth a close look by any operators able to afford replacement vehicles in the depths of a recession.

We can only guess how much better these engines might have been if their designers had not been forced to spend so much of their time on emissions control. Let's hope they won't have to make many more sacrifices in the run-up to 1996.

L] by Danny Coughlan