• DEMOUNTABLE DISTRIBUTION 10

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

by Alan Bunting, MIMechE

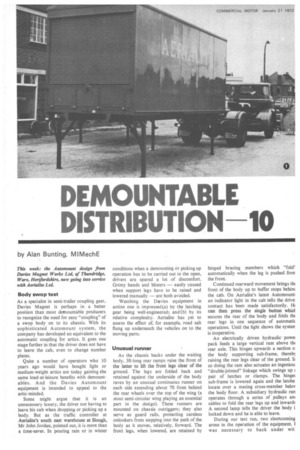

This week: the Automount design from Davies Magnet Works Ltd, of Thundridge, Ware, Hertfordshire, now going into service with Aerialite Ltd.

Body swop test

As a specialist in semi-trailer coupling gear, Davies Magnet is perhaps in a better position than most demountable producers to recognize the need for easy "coupling" of a swop body on to its chassis. With its sophisticated Automount system, the company has developed an equivalent to the automatic coupling for artics. It goes one stage further in that the driver does not have to leave the cab, even to change number plates.

Quite a number of operators who 10 years ago would have bought light or medium-weight artics are today gaining the same load-at-leisure benefits with demountables. And the Davies Automount equipment is intended to appeal to the artic-minded.

Some might argue that it is an unnecessary luxury, the driver not having to leave his cab when dropping or picking up a body. But as the traffic controller at Aerialite's south east warehouse at Slough, Mr John Jordan, pointed out, it is more than a time-saver. In pouring rain or in winter conditions when a demounting Or picking up operation has to be carried out in the open, drivers are spared a lot of discomfort. Grimy hands and blisters — easily caused when support legs have to be raised and lowered manually — are both avoided.

Watching the Davies equipment in action one is impressed(a) by the latching gear being well-engineered.; and (b) by its relative complexity. Aerialite has yet to assess the effect of, for example, road salt flung up underneath the vehicles on to the moving parts.

Unusual runner

As the chassis backs under the waiting body, 3ft-long rear ramps raise the front of the latter to lift the front legs clear of the ground. The legs are folded back and retained against the underside of the body raves by an unusual continuous runner on each side extending about 7ft from behind the rear wheels over the top of the wing (a stout semi-circular wing playing an essential part in the design). These runners are mounted on chassis outriggers; they also serve as guard rails, protecting careless onlookers from stepping into the path of the body as it moves, relatively, forward. The front legs, when lowered, are retained by hinged bracing members which "fold' automatically when the leg is pushed frorr the front.

Continued rearward movement brings thc front of the body up to buffer stops behinc the cab. On Aerialite's latest Automount: an indicator light in the cab tells the drive. contact has been made satisfactorily. IL can then press the single button whicl secures the rear of the body and folds th( rear legs in one sequence of automatic operations. Until the light shows the systenis inoperative.

An electrically driven hydraulic powel pack feeds a large vertical ram above th( rear axle. This hinges upwards a section o the body supporting sub-frame, therebl raising the rear legs clear of the ground. It so doing the ram also actuates an ingeniou: "double-jointed" linkage which swings up ( pair of latches or clamps. The hinge( sub-frame is lowered again and the latche locate over a mating cross-member belov the body floor. A subsidiary hydraulic ran operates through a series of pulleys an cables to fold the rear legs up and inwardE A second lamp tells the driver the body i locked down and he is able to leave.

During our test run, two shortcoming arose in the operation of the equipment. 1 was necessary to back under wit reasonable sharpness to ensure that the body and chassis engaged positively — resulting in the metal feet of the rear legs juddering across the concrete, even with a load of around 6 tons aboard. And, when demounting, an outrigger supporting the chassis ramps repeatedly fouled the offside front leg support stay.

Another criticism is the need for accuracy in positioning transversely the rear of the chassis as it is backed up to engage with the body. Thereafter, alignment is automatic, the body runners "straddling" the chassis sub-frame longitudinals, although unless the driver keeps well in line there is a good deal of resistance apparent, from rubbing contact between the two long members.

Any transport manager who opts for simplicity in his equipment as a guarantee of reliability could be forgiven for thinking twice about the Automount equipment. Diligent maintenance is needed, particularly in the winter, to keep the equipment running smoothly. Initially, Davies Magnet is to keep Aerialite's vehicles serviced.

There are, however, obvious attractions in a system — the Automount being the sole example, at present — where every function is controlled from the cab. Not surprisiimly. the Davies equipment scores on speed of operation. The box with 6 tons of payload was dropped in lmin 40sec. Unusually. the remounting operation was even quicker, the sequence occupying just 60see.

Service experience Aerialite, at the time of my visit to Slough had six Leyland Mastiff 16 tons gvW chassis equipped with Davies Automount base units, working with seven 20ft box van bodies built by Bailey Bodywork of Biddulph, Staffs. Eventually, the company will have 12 bodies and nine chassis.

Most of Aerialite's loads consist of reels of cable, in all shapes. sizes and types. Loading can take up to an hour per vehicle. With fixed-bodied vans, it was found that loading had to be carried out either late in the afternoon or — for late arrivals — the next morning. A shortage of suitable warehouse staff at Slough ruled out what would in any case be expensive evening overtime working.

Loading of swop-bodies during normal hours enables vehicles to make an early start on high mileage hauls — to Norwich, for example -and into central London to beat commuter traffic.

Mr Jordan and his drivers are enthusiastic about the Davies demountables, particularly now that the warning lights have been added as a safeguard against faulty operation. He is particularly pleased with the unit's performance when bodies are

loaded up their full o,w — a payload of around 10 tons. Few rival systems are able to cope with such high weights.