The Latest Automatically Variable Gear

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

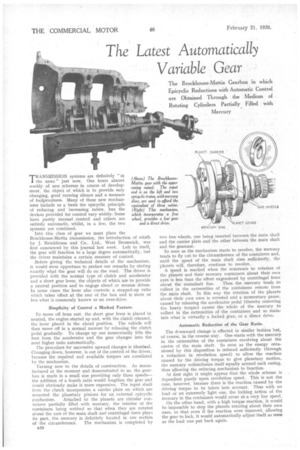

The Brockhouse-Mattia Gearbox in which Epicyclic Reductions with Automatic Control are Obtained Through the Medium of • e• Rotating Cylinders Partially. Filled with Mercury TRANSMISSION systems are definitely "in 1 the news" just now. One hears almost weekly of new _schemes in course of development, the object of which is to provide easy changing, good running silence and a measure of foolproofness. Many of these new mechanisms include -as a basis the epicyclic principle of reducing andY increasing ratios, but the devices provided for control vary widely. Some have purely manual control and others are entirely automatic, whilst, in a few, the two systems are combined.

Into this class of gear we must place the Brockhouse-Mattia transmission, the introduction of which by J. Brockhouse and Co., Ltd., West Bromwich, was first announced by this journal last week. Left to itself, the gear will function to a large degree automatically, but the driver maintains a certain measure of control.

Before giving the technical details of the mechanism, it would seem opportune to preface our remarks by stating exactly what the gear will do on the road. The driver is provided with the normal type ofclutch and accelerator and a short gear lever, the objects of which are to provide a neutral position and to engage ahead or reverse drives. In some cases the lever also controls a stepped-up ratio which takes effect at the rear of the box and is more or less what is commonly known as an over-drive.

Simplicity of Control a Marked Feature.

To move off from rest, the short gear lever is placed in neutral, the engine started up and, with the clutch released, the lever placed in the ahead position. The vehicle will then move off in a normal manner by releasing the clutch pedal gradually. To change up one momentarily lifts the foot from the accelerator and the gear changes into the next higher ratio automatically.

The procedure for successive upward changes is identical. Changing down, however, is out of the control of the driver, because the required and available torques are correlated by the mechanism.

Turning now to the details of construction. As manufactured at the moment and demonstrated to us, the gearbox is made in a small size providing only three speeds— the addition of a fourth ratio would lengthen the gear and would obviously make it more expensive. The input shaft from the clutch incorporates a carrier plate on which are mounted the planetary pinions for an external epicyclic

mechanism. Attached to the planets are circular containers partially filled with mercury, the interior of the containers being webbed so that when they are rotated about the axis of the main shaft and centrifugal force plays its part, the mercury is definitely located in one section of the circumference. The mechanism is completed by

B30

two free wheels, one being inserted between the main shaft and the carrier plate and the other between the main shaft and the gearcase.

So soon as the mechanism starts to revolve, the mercury tends to fly out to the circumference of the containers and, until the speed of the main shaft rises sufficiently, tbe planets will, therefore, continue to revolve. A speed is reached when the resistance to rotation of the planets and their mercury containers about their own axes is less than the effort engendered by centrifugal force about the mainshaft line. Then the mercury tends to collect in the extremities of the containers remote from the main shaft. In this way the rotation of the planets about their own axes is arrested and a momentary pause, caused by releasing the accelerator pedal (thereby removing the heavy torque) causes the whole of the mercury to collect in the extremities of the containers and so maintain what is virtually a locked gear, or a direct drive.

Automatic Reduction of the Gear Ratio.

The downward change is effected in similar fashion but, of course, in the reverse way. One starts with the mercury in the extremities of the containers revolving about the centre of the main shaft. So soon as the energy occasioned by this disposition is reduced sufficiently (through a reduction in revolution speed) to allow the reaction caused by the driving torque to give planetary motion, the mercury redistributes itself equally around each casing, thus allowing the reducing mechanism to function, At first sight it might appear that the whole scheme is dependent purely upon revolution speed. This is not the case, however, because there is the reaction caused by the driving torque to be taken into account. Thus with no load or an extremely light one, the locking action of the mercury in the containers would occur at a very low speed. On the other hand, with a high torque reaction, it would be impossible to stop the planets rotating about their own axes, so that even if the reaction were removed, allowing the gear to lock, it would automatically adjust itself so soon as the load was put back again.