GETTING DOWN TO GROUND LEVEL.

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

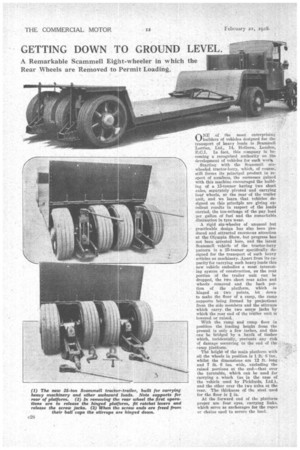

A Remarkable Scammell Eight-wheeler in which the Rear Wheels are Removed to Permit Loading,

ONE of the most • enterprising builders of vehicles designed for the transport 9f heavy loads is Seammell Lorries, Ltd., 14,• Holborn, London, J±1.0.1. In fact, this company is becoming a recognized authority on the development of vehicles for such wort.,

Starting with the Scammell sixwheeled tractor-lorry, which, of course, still forms its principal product in respect of numbers, the successes gained with this machine encouraged the buildjug of a 15-tortner having two short axles, separately pivoted and carrying fold wheels, at the rear of the trailer unit, and we learn that vehicles designed on this principle are giving excellent results in respect of the loads carried, the ton-mileage of the pay load per gallon of fuel and the remarkable diminution in tyre wear.

A rigid six-wheeler of unusual but practicable design has also been Produced and attracted enormous attention at the Olympia Show, but progress has not been arrested here, and the latest Scammell vehicle of the tractor-lorry pattern is a 25-tanner specifically designed for the transport of such heavy articles as machinery. Apart from its capacity for carrying such heavy loads this new vehicle embodies a most interest. ing system of construction, as the rear portion of the trailer unit can be dropped, the two short rear axles and wheels removed and the back portion of the platform, which is hinged at two points, let down to make the floor of a ramp, the ramp supports being formed by projections from the side members and the stirrups which carry the two screw jacks by which the rear end of the ti-ailer unit is lowered or raised..

With the ramp and ramp floor in position the loading height from the ground is only a few inches, and this can be bridged by a baulk of timber which, incidentally, prevents any risk of damage occurring to the end of the ramp platform.

Theheight Of the main platform with all the wheels in position is 1 ft. 8 ins, whilst the dimensions are 12 ft.long and 7 ft. 6 ins, wide, excluding the raised portions at the end—that over the turntable, which can be used for carrying a winch Oa in the case of the vehicle used by Pickfords, Ltd.), and the other over the two axles at the rear. The thickness of the steel used for the floor is 2

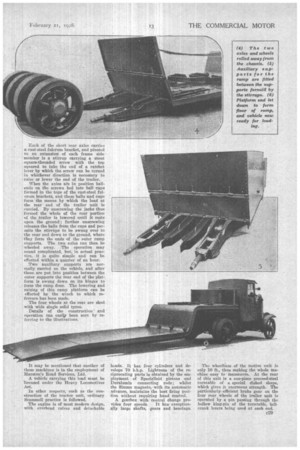

At the forward end of the platform proper are four eyes, carrying links, which serve as anchorages for the ropes or chains used to secure the load..

Each of the short rear axles carries a east-steel fulcrum bracket, and pivoted to an extension; of each frame side member is a stirrup carrying a stout square-threaded screw with the tap squared to take the end of a ratchet lever by which the screw can be turned • in whichever direction is necessary to raise or lower the end of the trailer.

When the axles ate in position ballends on the screws bed into ball cups formed in the tops of the cast-steel fulcrum brackets, and these balls and cups form the means by which the load at the rear end of the trailer unit is carried. By unscrewing the jacks thus formed the whole of the rear portion of the trailer is lowered until it rests upon the ground; further unscrewing releases the balls from the cups and permits the stirrups to be swung over to the rear and down to the ground, where they form the ends of the outer ramp supports. The two axles can then be wheeled away. The operation may sound complicated, but, in actual practice, it is quite simple and can be effected within a quarter of an hour.

Two auxiliary supports are normally carried on the vehicle, and after these are put into position between the enter supports the rear end of the plat-. form is swung down on its hinges to form the ramp floor. The lowering and raising of this ramp platform can be effected by the winch to which reference has been made.

The four wheels at the rear are shod with wide single solid tyres.

Details of the constructionand operation can easiLy been seen by referring to the illustrations.

It may be mentioned that another of these machines is in the employment of Marston's Road Services, Ltd.

A vehicle carrying this load must be licensed under the Heavy Locomotives Act.

In other respects, such as the construction of the tractor unit, ordinary Scammell practice is followed.

The engine is of most modern design, with overhead valves and detachable

heads. It has four cylinders and develops 70 b.b.p. Lightness of the reciprocating parts is obtained by the employment of Specialloid pistons and Duralumin connecting rods ; whilst the Simms magneto, with its automatic advance, maintains the best firing position without requiring hand control.

A gearbox with central change pro

vides four speeds. It has exceptionally large shafts, gears and bearings.

The wheelbase of the motive unit is only 10 ft., thus making the whole machine easy to manZeuvre. At the rear of this unit is a one-piece pressed-steel turntable of a special dished shape, which gives it enormous strength. The particularly-efficient brake gear on the four rear wheels of the trailer unit is operated by a pin passing through the hollow king-pin of the turntable, bell crank levers being used at each end.