FINE PERFORMANCE by a

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

SUNBEAM. B.T.H. TROLLEYBUS

WHEN planning a test run on a trolleybus the conditions of service under which such a vehicle operates must be taken fully into consideration. Furthermore, one is limited in a choice of routes, the only roads available being those served by the overhead electric supply. This means that the route is confined to the precincts of a large town, where traffic conditions call for moderate speeds and frequent stops. This is just as it should be, for a trolleybus is essentially a vehicle suited to the requirements of " peak " loads and, by reason of the ease of control, absence of gear-changing, etc., stopping and starting make no great demand upon the driver.

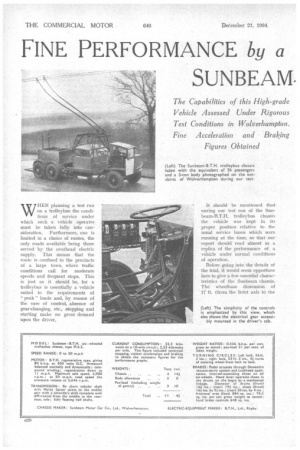

It should be mentioned that during our test run of the Sun beam-13.T.H. trolleybus chassis the vehicle was kept in. its proper position relative to the usual service buses which were running at the time, so that our report should read almost as a replica of the performance of a vehicle under normal conditions of operation.

nefore going into the details Of the trial, it would scent opportune here to give a few essential charac teristics of the Sunbeam chassis. The wheelbase dimension of 17 ft. (from the front axle to the centre of the bogie) gives sufficient chassis space for a 50-passenger body. Accordingly, the vehicle carried a test load equivalent to the weight of this number of persons, plus a body allowance of 3 tons —a reasonable figure in these days of light-alloy construction.

The motor, of the compoundwound type, gives regeneration of current to the line down to a speed of 1.1 m.p.h. The maximum safe speed of the motor is 3,000 r.p.m., whilst the maximum road speed of vided in the contactor • circuits. All cables are encased in flexible metallic tubing.

It is interesting to note that, when descending a steep hill, provision is made to give rheostatic braking to limit the speed of the bus to approximately 8 m.p.h. This braking does not depend upon the 500-volt supply and is thus unaffected should a trolley leave the overhead line. If the power fails when ascending a hill, the armature and series field are short-circuited. The obvious conse

quence of this is a cumulative rise in output (the motor is, of course, now running as a dynamo), due to the absence of any resistance in the circuit, with an immediate and abnormally heavy increase in load, which prevents the vehicle from running backwards at a speed greater than. approximately 2 m.p.h.

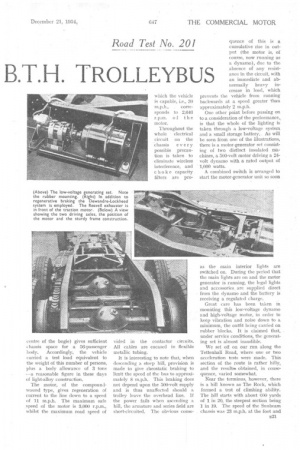

One other point before passing on to a consideration of the performance„ is that the whole of the lighting is taken through a low-voltage system and a small storage battery.. As will be seen from one of the illustrations, there is a motor-generator set consisting of two distinct insulated machines, a 500-volt motor driving a 24volt dynamo with a rated output of 1,000 watts.

A combined switch is arranged to start the motor-generator unit so soon as the main interior lights are switched on. During the period that the main lights are on and the motor generator is running, the legal lights and accessories . are supplied direct from the dynamo and the battery is receiving a regulated charge.

Great care has been taken in mounting this low-voltage dynamo and high-voltage motor, in order to keep vibration and noise down to a minimum, the outfit being carried on rubber blocks. It is claimed that, under service conditions, the generating set is almost inaudible.

We set off on our run along the Tettenhall Road, where one or two acceleration tests were made. This section of the route is rather hilly, and the result9 obtained, in consequence, varied somewhat.

Near the terminus, however, there is a bill known as The Rock, which formed a test of climbing ability. The hill starts with about COO yards of 1 in 20, the steepest section being 1 in 19. The speed of the Sunbeam chassis was 23 in.p.h, at the foot and the gradient naturally caused the vehicle gradually to slow down until a steady speed of 15 m.p.h. was recorded. When the gradient eased, the speed crept up again, until, at a point near the terminus, nearly 20 m.p.h. was recorded by the speedometer. The climb was made at an average of 17.4 m.p.h.—.-a good performance.

After turning at the terminus, we were able to assess the regenerating characteristics of the motor. Although baulked on two occasions during the descent of The Rock, we actually recorded one-third of a kilowatt returned to the line, and it is obvious that the Sunbeam company's claim of half a kilowatt per descent is quite reasonable.

A run through the town took us to the Willenhall Road, which is much flatter than the Tettenhall Road. There we were able to obtain really consistent acceleration times, and in this connection a tribute may be paid to the Wolverhampton Corporation electricity supply, for the variation in times did not amount to more than 10 per cent., no matter where the feeders to the overhead wires were in relation to the position of the vehicle.

It is of note that the controller is operated by an accelerator pedal of the easy plate type, and actuates a master switch. The last-named brings into use contactors which carry the main current, the controller switch itself being subjected to a light load sufficient to operate solenoids on the contactor panel.

This panel, by the way, is carried in the driver's compartment in an accessible position, where the contactors are enclosed in neat, polished, wooden cabinets with readily detachable covers lined with asbestos. All the contacts are of the self-cleaning type, closing with a combined rolling and sliding motion and opening with a quick, positive action, under pressure from the compression springs, when the coil circuit is interrupted.

We have already made reference to the efficiency of the brakes. When it is considered that, using only the pedal the fully laden vehicle can be pulled up from 30 m.p.h. in under 'TO ft., our favourable comments will be better understood. It should be added that the retarding mechanism 1322 works smoothly and silently, and it is obvious, from an examination of the road over which the braking tests had been made, that the SunbeamLockheed system really does live up to its reputation of giving a balanced braking effect on all wheels.

With regard to the hand brake, which applies the shoes in the four rear drums through a mechanical hook-up, this proved effective, although, naturally, not so efficient as the power-assisted system.

Apart from the large braking surface (no fewer than 884 sq. ins, of friction fabric are brought into con tact by the pedal) the application of the pedal pressure to the shoes within the drums calls for comment In the first place, it should be mentioned that the vacuum required by the Dewandre servo-motor is created by a Reavell exhauster.

By direct linkage (which, incidentally, precludes any possibility of danger arising from a failure in the vacuum service), the servo is coupled to the Lockheed master-cylinder box, which, in the Sunbeam application, has three cylindees—one for each axle—the outer casing acting as a reservoir by which the cylinders and the pipe lines are maintained full of fluid. There is a compensating device—exclusive to Sunbeam chassis— which ensures that the ' pressures in the master cylinders are equal.

In the unlikely event of a pipe leaking. however, a rubber cup and a needle valve, fitted to each cylinder, seal the offending component, thus full service pressure can be applied to the remaining two cylinders.

Taken on an average, the Wolverhampton trolleybus service calls for about seven stops per mile, so we instituted a test to see how the vehicle behaved over a distance of 250 yds., starting from and finishing at rest. On several occasions this distance was covered in 26 secs., the maximum time recorded under crowded traffic conditions being 31 secs. It will be seen, therefore, that, exclusive of waiting time, an average speed

approaching 20 m.p.h. could be attained.

One other special feature should be mentioned. The end thrust, caused by the sliding splines 60 70 80 90 100 on the propeller shaft (during upand-down wheel movements), is not taken by the armature bearings of the motor, because a special thrust bearing is used at the rear of the

casing. The thrust is, of course, rather high when the motor is driving on anything like full torque.

To test the resistances, which, by the way, are wirebound, rustless, jointless and well ventilated, the accelerator pedal was depressed to the first notch with the current switched on and the brake applied, and held in that position for 4 minute. Although, naturally, the resistances became heated, they did not reach a red heat and the vehicle promptly moved off upon the brakes being released.

Summed up, the Sunbeam-B.T.H. trolleybus is a product of which the maker may justly be proud. It is efficient, well finished and built of high-grade materials.