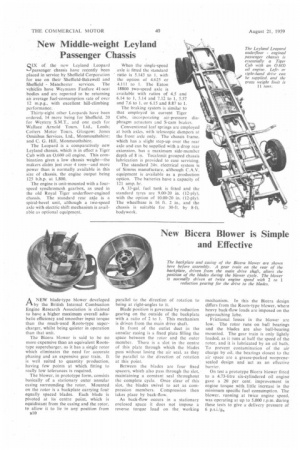

New Middle-weight Leyland Passenger Chassis

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

QIX of the new Leyland Leopard 1,-/passenger chassis have recently been placed in service by Sheffield Corporation for use on their Sheffield-Bakewell and

Sheffield Manchester services. The vehicles have Weymann Fanfare 41-seat bodies and arc reported to be returning an average fuel-consumption rate of over 12 m.p.g., with excellent hill-climbing performance.

Thirty-eight other Leopards have been ordered, 14 more being for Sheffield. 20 for Western S.M.T.. and one each for Wallace Arnold Tours. Ltd., Leeds; Cotters Motor Tours, Glasgow; Jones Omnibus Services, Ltd., Monmouthshire; and C. G. Hill, Monmouthshire.

The Leopard is a comparatively new Leyland chassis, which is in effect a Tiger Cub with an 0.600 oil engine. This combination gives a low chassis weight—the makers claim just over 4 tons—and more power than is normally available in this size of chassis, the engine output being 125 b.h.p. at 1,800.

The engine is unit-mounted with a fourspeed synchromesh gearbox, as used in the old Royal Tiger underfloor-engined chassis. The standard rear axle is a spiral-bevel unit, although a two-speed axle with electric shift mechanism is available as optional equipment. When the single-speed axle is fitted the standard ratio is 5.143 to I. with the option of 4.625 or 4.111 to I. The Eaton 18800 two-speed axle is available with ratios of 4.5 and 6.14 to 1, 5.14 and 7.12 to 1, 5.57 and 7.6 to I. or 6.15 and 8.87 to 1.

The braking system is similar to that employed in current Tiger Cubs, incorporating air-pressure diaphragm actuators and S-cam brakes.

Conventional leaf springs are employed at both axles, with telescopic dampers at the front axle only. The chassis frame, which has a slight step-up over the rear axle and can be supplied with a drop rear extension, has a maximum side-member depth of 8 in. Tecalemit grouped chassis lubrication is provided to ease servicing.

The standard 24v. electrical system is of Simms manufacture, although C.A.V. equipment is available as a production option. The batteries have a capacity of 121 amp. hr.

A 33-gal, fuel tank is fitted and the standard tyres are 9.00-20 in. (12-ply), with the option of 10.00-20 in. (12-ply). The wheelbase is 16 ft. 2 in., and the chassis is suitable for 30-ft. by 8-ft. bodywork.