Air Starting for Oil Engines

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

JT will be interesting if the old controversy as to the relative merits of compressed air and electricity as a source of power for engine starting, long moribund in respect of petrol engines, should be revived in connection with compression-ignition engines. There appears to be every prospect of such an occurrence.

There are two important factors that distinguish the oil engine from the petrol unit with regard to the method of starting. A somewhat greater torque is necessary for the oil engine than for the other type, which involves the use of a more powerful starter and, ergo, greater consumption of current.

Then there is the fact that, apart from starting, there is no need for any electrical equipment for the oil engine, so far as its normal operation is concerned.

A compressed-air starter has the advantage that every part of its mechanism is capable of being handled by any mechanic.

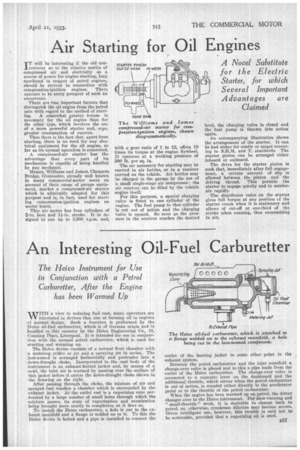

Messrs. Williams and James, Chequers Bridge, Gloucester, already well known to many commercial-motor users on account of their range of garage equipment, market a compressed-air starter which is admirably adapted for this purpose and is, in fact, used for starting compression-ignition engines on motor boats.

This air motor has four cylinders of 2-in, bore and 1i-in. stroke. It is designed td run up to 3,500 r.p.m. and, with a gear ratio of 1 to 12, offers 10 times its torque at the engine flywheel. It operates at a working pressure of 300 lb. per sq. in.

The air necessary for starting may be carried in air bottles, or in a receiver carried on the vehicle. Air bottles may be charged in the garage by the use of a small single-stage air compressor; the air receiver can be filled by the vehicle engine itself. • For this purpose, a special charging valve is fitted to one cylinder of the engine. The fuel pump to that cylinder is cut out of action and the charging valve is opened. So soon as the pressure in the receiver reaches the desired level, the charging valve is closed and the fuel pump is thrown into action again.

An accompanying illustration shows the arrangement of the starter. It can be had either for cradle or spigot mounting to S.M.M. and T. standards. The starter pinion can be arranged either inboard or outboard.

The drive for the starter pinion is such that, immediately after full engagement, a certain amount of slip is allowed between the pinion and the driving thread. This permits the starter to engage quietly and to accelerate rapidly.

The distributor valve on the starter gives full torque at any position a the starter crank when it is stationary and allows of cut-off at one-third of the stroke when running, thus economizing in air.