Improving the Springing on Heavy Wagons.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

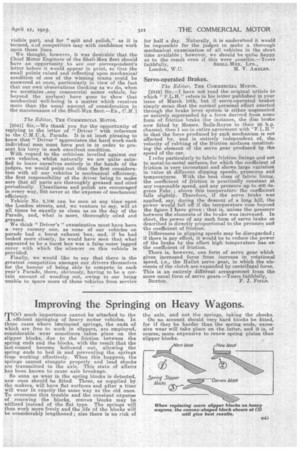

rF00 much importance cannot be attached to the efficient springing of heavy motor vehicles. In those cases where Issininated springs, the ends of which are free to work in slippers, are employed, considerable wear sometimes takes place on the slipper blocks, due to the friction between the spring ends and the blocks, with the result that the last-named become hollowed out, allowing the spring ends to bed in and preventing the springs from working effectively. When this happens, the springs cannot elongate properly and load shocks are transmitted to the axle. This state of affairs has been known to cause axle breakage.

So soon as wear in the spring blocks is detected, new ones should be fitted. These, as supplied by the makers, will have flat surfaces and after a time will wear in exactly the same way as the old ones. To overcome this trouble and the constant expense of . renewing the blocks, convex blocks may be utilized instead of the flat type. The springs will then work more freely and the life of the blocks will be considerably lengthened ; also there is no risk of the axle, and not the springs, taking the shocks.

On no account should very hard blocks be fitted, for if they be harder than the spring ends, excessive wear will take place on the latter, and it is, of course, more expensive to renew spring plates than slipper blocks.