REDUCING THE WEIGH'] PASSENGER VEHICLES.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

The Possibilities of Higher Engine Spe Advantages of Six-cylinder Engines.

Influence

wheel Drive, and Six-wheel Designs. eight .per Passenger Carried and its ng Costs.

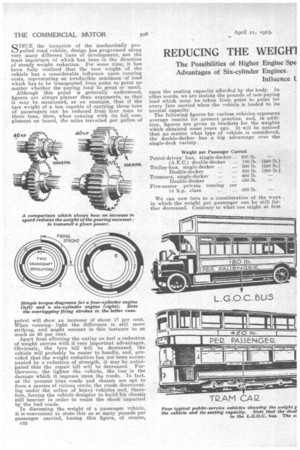

Q INCE the inception of the mechanically pro

pelled road vehicle, design has progressed along very many different lines of development, not the least important of which has been in the direction of steady weight reduction. For some time, it has been fully realized that the tare weight of the vehicle has a considerable influence upon running costs, representing an irreducible minimum of load which has to be transported from point to point no matter whether the paying load be great or small. Although this point is generally understood, figures are always plainer than arguments, so that it may be mentioned, as an example, that if the tare weight of a bus capable of carrying three tons of passengers can be reduced from four tons to three tons, then, when running with its full complement on board, the miles travelled. per gallon of petrol will show an increase of about 17 per cent. When runninglight the difference is still more striking, and might amount in this instance to as much as 30 per cent.

Apart from affecting the outlay on fuel a reduction of weight carries with it very important advantages. Obviously, the tyre bill will be decreased, the vehicle will probably be easier to handle, and, provided that the weight reduction has not been accompanied by a reduction of strength, it may be anticipated that the repair bill will be decreased. Furthermore, the lighter the vehicle, the less is the damage which it imposes upon the roads. In fact, at the present time roads and chassis are apt to form a species of vicious circle, the roads deteriorating under the action of heavy vehicles and, therefore, forcing the vehicle designer to build his chassis still heavier in order to resist the shock imparted by the had roads.

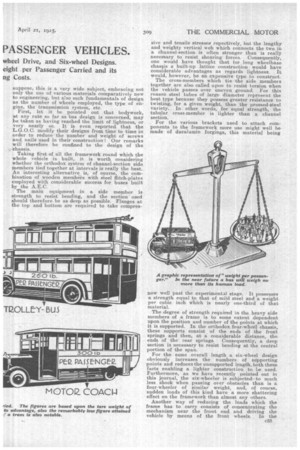

In discussing the weight of a passenger vehicle, it is•convenient to state this as so rgany pounds per passenger carried, basing this figure, of course, e32 upon the seating capacity afforded by the body. In other words, we are stating the pounds of non-paying load which must be taken from point to point for every fare carried when the vehicle is loaded to its normal capacity.

The following figures for various vehicles represent average results for present practice, and, in• addition, figures are given in brackets for the weights which obtained some years ago. It will be noticed that no matter what type of vehicle is considered, the double-decker has a big advantage over the single-deck variety.

We can now turn to a consideration of the ways . in which the weight per passenger can be still further decreased. Contrary to what one might at first suppose, this is a very wide subject, embracing not only the use of various materials comparatively new to engineering, but also such fundamentals of design as the number of wheels employed, the type of engine, the transmission system, etc. First, let it be pointed out that bodywork, at any rate so far as bus design is concerned, may be taken as having reached the limit of lightness, or very nearly so. It is even reported that the L.G.O.C. modify their designs from time to time in order to reduce the number and weight of screws and nails used in their construction! Our remarks will therefore be confined to the design of the chassis.

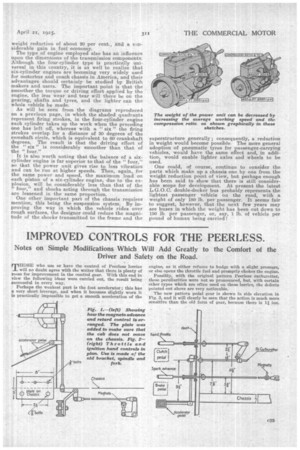

Taking fiist of all the framework round which the whole vehicle is built, it is worth considering whether the orthodox system of channel-section side members tied together at intervals is really the best. An interesting alternative is, of course, the combination of wooden membe-is with steel flitch-plates employed with considerable success for buses built by the A.E.C.

The main equipment in a side member is strength to resist bending, and the section used should therefore be as deep as possible. Flanges at the top and bottom are required to take compres sive and tensile stresses repectively, but the lengthy and weighty vertical web which connects the two in a channel-section is often stronger than is really necessary to resist shearing forces. Consequently, one would have thought that for long wheelbase chassis a built-up lattice construction would have considerable advantages as regards lightness. It would, however, be an expensive type to construct. The cross-members which tie the side members together are also called upon to resist torsion when the vehicle passes over uneven ground. For this reason steel tubes of large diameter represent the best type because they possess greater resistance to twisting, for a given weight, than the pressed-steel variety. In other words, for equal strength, the tubular cross-member is lighter than a channel section.

For the various brackets used to attach components to the framework more use might well be made of duralumin forgings, this material being now well past the experimental stage. It possesses a strength equal to that of mild steel and a weight per cubic inch which is nearly one-third of that material.

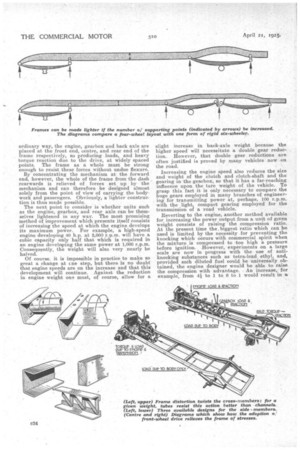

The degree of strength required in the heavy side members of a frame is to some extent dependent upon the position and number of the points at which it is supported. In the orthodox four-wheel chassis, these supports consist of the ends of the front springs and then, at a considerable distance, the ends of the rear springs. Consequently, a deep section is necessary to resist bending at the central portion of the span.

For the same overall length a six-wheel design obviously increases the numbers of stipporting points and reduces the unsupported length, both these facts enabling a lighter construction to be used. Furthermore, as we have recently pointed out in this journal, the six-wheeler is subjected--to much less shock when passing over obstacles than is a four-wheeler of similar weight, and, of course, sudden loads of this kind have a more shattering effect on the framework than almost any others.

Another way of reducing the loads which the frame has to carry consists of concentrating the mechanism near the front end and driving the vehicle by means of the front wheels. In the

ordinary way, the engine, gearbox and back axle are placed at the front end, centre, and rear end of the frame respectively, so producing loads, and heavy torque reaction due to the drive, at widely spaced points. The frame as a whole must be strong enough to resist these forces without undue flexure.

By concentrating the mechanism at the forward end, however, the whole of the frame from the dash rearwards is relieved of forces set up by the mechanism and can therefore be designed almost solely from the point of view of carrying the bodywork and passengers. Obviously, a lighter construction is thus made possible.

The next point to consider is whether units such as the engine, gearbox, and rear axle can be themselves lightened in any way. The most promising method of improvement which presents itself consists of increasing the speed at which the engine develops its maximum power. For example, a high-speed engine developing 40 h.p. at 2,000 r.p.m. will have a cubic capacity only half that which is required in an engine developing the same power at 1,000 r.p.m. Consequently, the weight will also very nearly be halved.

Of course, it is impossible in practice to make so great a change at cne step, but there is no doubt that engine speeds are on the increase and that this development will continue. Against the reduction in engine weight ons must, of course, allow for a slight increase in back-axle weight because the higher speed will necessitate a double gear reduction. However, that double gear reductions are often justified is proved by many vehicles now -on the road.

Increasing the engine speed also reduces the size and weight of the clutch and clutch-shaft and the gearing in the gearbox, so that it has a far-reaching influence upon the tare weight of the vehicle. To grasp this fact it is only necessary to compare the huge gears employed in many branches of engineering for transmitting power at, perhaps, 100 r.p.m. with the light, compact gearing employed for the transmission of a road vehicle.

Reverting to the engine, another method available for increasing the power output from a unit of given weight consists of raising the compression ratio. At the present time the, biggest ratio which can be used is limited by the necessity for preventing the knocking which occurs with commercial spirit when the mixture is compressed to ,too high a pressure before ignition. However, experiments on a large scale are now in progress with the use of anti. knocking substances such as tetra-lead ethyl, and, provided such diluted fuel could be universally obtained, the engine designer would be able to raise the compression with advantage. An increase, for example, from 4i to 1 to 6 to 1 would result in a

weight reduction of about 20 per cent, and a ensiderable gain in fuel economy.

The type of engine employed also has an influence upon the dimensions of the transmission components. Although the four-cylinder type is practically universal in this country, it is as well to realize that six-cylinder engines are becoming very widely used for motorbus and coach chassis in America, and their advantages should certainly be studied by British makers and users. The important point is that the smoother the torque or driving effort applied by the engine, the less wear and tear will there be on the gearing, shafts and tyres, and the lighter can the whole vehicle be made.

As will be seen from the diagrams reproduced on a previous page, in which the shaded quadrants represent firing strokes, in the four-cylinder engine each cylinder takes up the work when the preceding one has left off, whereas with a " six " the firing strokes overlap for a distance of 30 degrees of the camshaft circle, which is equivalent to 60 crankshaft degrees. The result is that the driving effort of the " six" is considerably smoother than that of the " four."

It is also worth noting that the balance of a sixcylinder engine is far superior to that of the " four," so that the power unit gives rise to less vibration and can be run at higher speeds. Then, again, for the same power and speed, the maximum load on each piston of a six-cylinder engine, due to the explosion, will be considerably less than that of the " four," and shacks acting through the transmission are lessened in the same proportion. One other important part of the chassis requires mention, this being the suspension system. By improving the way in which the vehicle rides over tough surfaces, the designer could reduce the magnitude of the shocks transmitted to the frame and the superstructure generally ; consequently, a reduction in weight would become possible. The more general adoption of pneumatic tyres for passenger-carrying vehicles, would have the same effect and, in addition, would enable lighter axles and wheels to be used.

One could, of course, continue to consider the parts which make up a chassis one by one from the weight reduction point of view, but perhaps enough has been said to show that there is still considerable scope for development. At present the latest L.G.O.C. double-decker bus probably represents the lightest passenger vehicle on the road, with a weight of only 180 lb. per passenger. It seems fair to suggest, however, that the next few years may see buses in which the weight has been cut down to 150 lb. per passenger, or, say, 1 lb. of vehicle per pound of human being carried