Economy and Higf THE BEDFORE Speeds With EYLAND

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A.M.I.R.T.E.

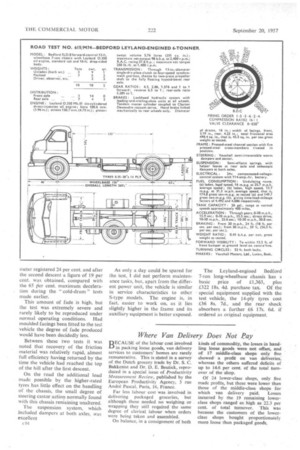

IN view of the many Bedford 7-tanners converted in the past by the installation of Leyland 0.350 oil engines, and the world-wide reputation that this unit has established for longevity and economy, it is not surprising that Vauxhall Motors, Ltd., now offer this engine in their 7-ton load carriers and 10-ton prime movers.

Thus equipped, the 7-ton chassis can deal ably with a payload exceeding 7+ tons (permitted when 8.2520-in. (14-ply) tyres are fitted) without fear. of overtaxing the power unit or drastically slowing-up the road performance.

The Leyland-engined chassis is decidedly more economical than the previous Bedford 7-ton oiler tested by The Commercial Motor. Even when driven under almost continuous fullthrottle conditions over an undulating route, the fuel-consumption rate was only 13.7 m.p.g., whilst at normal legal speeds the rate was 16 m.p.g.

Few mechanical alterations are necessary to accommodate the Leyland engine in the standard S-type 7-ton chassis. The principal changes are confined to the addition of a cross-member behind the power unit to carry the rear mountings, and the use of different gearbox ratios.

Standard Leyland mountings are employed at the front and rear of the engine and the low degree of vibration which was transferred to the chassis and cab is a noteworthy feature of the mounting layout.

The gearbox ratios have been changed to avoid dangerously high torque transference through the box and final drive, these two units having been weak spots of previous conversions. Higher indirect ratios are fitted, bottom and reverse gears now being 6.5 to 1, instead of the 7.059 to 1, ratio which is standard throughout the rest of the Bedford range.

Because the Leyland engine is slightly longer than other units employed in this chassis, the gearbox is about 1 in. farther back than standard. Although this does not sound much, it is sufficient to make gear changing a little awkward at times and, unless care is exercised, it is possible to knock the rear of the cab with either fist or elbow when moving the lever into the secondor

top-gear positions. Slightly more pronounced cranking of the lever should do much to remedy this defect. The staidard Bedford doubleskinned insulated engine cowl can not be used with the Leyland engine, and a plain sheet-metal cowl with felt interior lining and leather-cloth covering is employed. Nevertheless, engine noise in the cab is not excessive, particularly at road speeds of 30-35 m.p.h. in top gear. At no time during the test did the cowl become uncomfortably hot and no engine heat could be felt from the driving seat.

Carrying a test load of 7 tons

51 cwt. and complete with test equipment, Vauxhall driver and myself aboard, the chassis, which had a 16-f t.long drop-sided body, was tested at a gross weight of 10 tons 181 cwt. The manufacturers' recommended gross weight with 14-ply tyres is 10 tons 15.1 cwt., thus an overload of 31 cwt. was being carried: Using a calibrated test tank, the fuel-consumption runs were made along an undulating six-mile section of road between Barton and Clophill. Two runs were made, the first at high speed, with prolonged use of full throttle.

At times 45 m.p.h. was reached during this test, but traffic conditions were such that the average speed was only 31.3 m.p.h. The fuel-consumption rate was 13.75 m.p.g., which is

a reasonable figure in view of the conditions and one which should rarely be exceeded during normal operation.

The second test was made at nearer legal speeds, 30 na.p.h. being maintained for the greater part of the distance. This run produced a consumption rate of 16 m.p.g. A combination of the two results suggests that in general service the Leylandengined 7-tonner should return about 15 m.p.g. when laden, with an unladen figure not far short of 25 m.p.g.

Despite the high axle ratio and slight overload, acceleration through the gears up to 30 m.p.h. was rapid. The Bedford was well up to the standard normally found with vehicles of this weight, whilst the axle ratio has the advantage of giving a maximum speed of nearly 50 m.p.h.

When pulling away from 10 m.p.h. in top gear the engine and transmis sion were notably smooth and a reasonable rate of acceleration was measured, although during this test, somewhat naturally, the high axle ratio tended to put the chassis at a slight disadvantage. With an efficient synchromesh gearbox such as that fitted, drivers will not find it any hardship to use third gear at speeds up to 25 m.p.h., rather than labour the engine in direct drive.

Braking tests were made on a slightly damp road and locking of the rear wheels marred the results from 30 m.p.h. The brakes appear to be adequate at normal speeds, however, and on a completely dry road much shorter distances would have been recorded, particularly from 30 m.p.h.

Maximum hand-brake efficiency recorded from 20 m.p.h. was 26 per cent, and the rear wheels did not lock, despite the greasy road surface. Normally Bedford hand brakes are much more effective than this, and it is obvious that the rear brakes are working at their top limit when the chassis is running at nearly 11 tons gross weight.'

Bison Hill, a 1-mile climb with an average gradient of I in 101, was used for hill-climb and fade tests, which were conducted in an ambient temperature of 64° F. under wet conditions. At the bottom of the hill the engine coolant temperature was 172° F. and after a 5-minute 25second climb a rise of only 4° F. was recorded. No smoking was noticed at the exhaust outlet.

Bottom gear was used twice during the ascent, this ratio being engaged for a total time of 2 minutes. Although full throttle was used the whole time the low temperature rise indicates that the engine was not working hard, and it is only because of the wide gap between bottom and second ratios that the lowest gear had to be used.

Because of the power output of the Leyland unit, bottom gear becomes, in effect, an emergency low ratio, its use not being necessary when starting off on a level road, for instance. Even on the 1-in-61 gradient of Bison Hill, where the lorry was stopped during a second ascent, only half throttle was necessary to make a smooth restart in this ratio. There is thus ample power for all conditions likely to be encountered in Great Britain with a vehicle of this capacity.

The hill was descended twice to • check for fade resistance. Both runs were made \in neutral and each took 21 minutes. Forty seconds of this time was spent in top gear, with full throttle applied, on the less-steep section at the bottom of the hill.

Having used the foot brake to restrict the speed to approximately 20 m.p.h. during each descent, emergency full-pressure stops were made from this speed at the end of each test. On the first occasion the Tapley meter registered 24 per cent. and after the second descent a figure of 19 per cent. was obtained, compared with the 65 lier cent. maximum deceleration during the " cold-drum" tests made earlier.

This amount of fade is high, but the test was extremely severe and rarely likely to be reproduced under normal operating conditions. Had moulded facings been fitted to the test vehicle the degree of fade produced would have been decidedly less.

Between these two tests it was noted that recovery of the friction material was relatively rapid, almost full efficiency having returned by the time the vehicle had reached the top of the hill after the first descent.

On the road the additional load made possible by the higher-rated tyres has little effect on the handling of the chassis, the small degree of steering castor action normally found with this chassis remaining unaltered.

The suspension system, which included dampers at both axles, was excellent c14

As only a day could be spared for the test, I did not perform maintenance tasks, but, apart from the different power unit, the vehicle is similar in service characteristics to other S-type models. The engine is, in fact, easier to work on, as it lies slightly higher in the frame and its auxiliary equipment is better exposed. The Leyland-engined Bedford 7-ton long-wheelbase chassis has I basic price of £1,363, plus £322 18s. 4d. purchase tax. Of the special equipment supplied with the test vehicle, the 14-ply tyres cost £36 8s. 7d., and the rear shock absorbers a further £6 17s. 6d. if ordered as original equipment.