THE ENGINE, GEARBOX AND FINAL DRIVE.

Page 31

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The First of Two Articles which will Consider Present-day Design, Choice of Material and Methods of Construction Employed in the Manufacture of Commercial Motor Chassis.

THE USItIt, and particularly the user who has a fleet under his charge, is ever desirous of learning from his own experience and the experience of others what design or form of construction will give him the greatest service in his vehicles and will make for reliability and durability. He does not aim at intense originality or change, because he is not prepared to indulge in extensive and expensive experimenting. That he prefers to leave to others, which is one of the reasons why the private car is a very suitable medium for testing new ideas, and full well is it realized that but for the private car_and the enterprising motorists—who were engineers rather than carriage folk—of the latter years of the last century there would be no commercial motors to-clay.

The user, therefore, would rather know what present day methods and designs are giving the hest service and in what direction he should look fOr the particular qualities he desires. Simplicity in all that

• pertains to maintenance is important, because a vehicle is quicker back upon the road after examination, adjustment, or overhaul, but long life in every wearing part is more important still, because it makes for reliability in running, ensures the maintenance of schedule times in the collection or delivery of goods, and tends to reduce overhead charges.

It is meet, therefore, at this period, when the mind is centred upon the latest ideas of our manufacturers, to take a careful glance over the whole question of design, choice of material and methods of construction, and in this article we propose to consider the power unit and the transmission first of all, leaving other important details to a subsequent article.

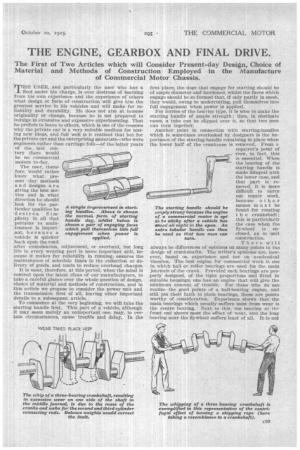

To commence at the very beginning, we will take_ the starting handle first. This part of a vehicle, although it may seem merely an unimportant one. may, in certain circumstances, cause trouble and delay. In the A simple improvement in starting handles. Above is shown the normal, form of starting handle dog, whilst below is shown a pair of engaging faces which pull themselves into full engagement when power is applied. first place, the dogs that engage for starting should be of ample diameter and hardened, whilst the faces which engage should be so formed that, if only partly in mesh, they would, owing to undercutting, pull themselves into full engagement when power is applied.

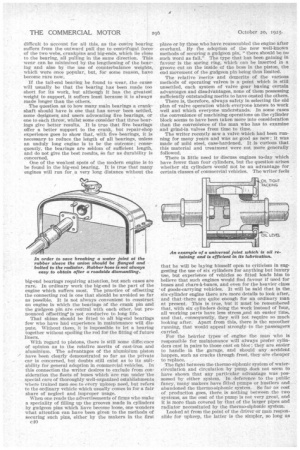

For lorries of the heavier type, it is wise to make the starting handle of ample strength ; then, in obstinate cases, a tube can be slipped over it, so that two men can turn together.

Another point in connection with starting-handles which is sometimes overlooked by designers is the im

portance of the starting-handle remaining in place when the lower half of the crankcase is removed. From a repairer's point of view, in fact, this is essential. When the bearing of the starting handle is . made integral with the lower case, and that part is removed, it-is more difficult to carry out repair work, because other means must be found for rotating t h e crankshaft ; this is particularly the ease when the flywheel is enclosed, as in unit construction.

There will always be differences of opinions on many points in the design of crankshafts. The writer's opinions-are, however, based on experience and not on academical theories. The best engine for commercial work is one in which ball or roller bearings are used for the main journals of the crank. Provided such bearings are properly designed, of the right proportions and fitted in suitable housings, one has an 'engine that will give the minimum amount of trouble. For those who do not realize the good points of a ball-bearing engine, and still pin their faith to plain bearings, these are points worthy of consideration. Experience shows that the main bearings which usually suffers most from wear is the centre bearing. Next to this, the bearing at rtm front end shows most the effect of wear, and the long hearing near the flywheel suffers least of all. It-is not The starting handle should be amply strong because the engine of a commercial motor is apt go be sticky after a vehicle has 'food all night in the open. An extra tubular handle can then he used so that two men can

turn. difficult to account for all this, as the centre bearing suffers from the outward pull due to centrifugal force of the two webs, crankpins and big-ends, which lie close to the bearing, all pulling in the same direction. This wear can be minimized by the lengthening of the bearing and also by the use of counterbalance weights, which were once popular, but, for some reason, have become rare now.

If the tail-end bearing be found to wear, The cause will usually be that the bearing has been made too short for its work, but although it has the greatest weight to support, it suffers least because it is always made longer than the others.

The question as to how many main bearings a crankshaft should have is one that has never been settled, some designers and users advocating five bearings, or one to each throw, whilst some consider that three bearings give better results. It is true that five bearings offer a better support to the crank but repair-shop experience goes to show that, with crank, -bearings, it is necessary to reduce the length of all hearings, unless an unduly long engine is to be the outcome; consequently, the bearings are seldom of sufficient length, and do not give the best results, so far as .durability is concerned.

One of the weakest spots of the modern engine is to be found in the big-end bearing. It is true that many engines will run for, a very long distance without the big-end bearings requiring attention, hut such cases are rare. In ordinary work the big-end is the part of the engine which suffers most. The practice of offsetting the connecting rod is one that should be avoided so far as possible. It is not always convenient to construct an engine in which the bearings of the crank pin and the gudgeon pin are central with each other, but pronounced offsetting is not conducive to long life.

That shims should be fitted to all big-end bearings few who have had experience in maintenance will dispute. Without them, it is impossible to let a bearing together without spoiling the rod for the fitting of future

With regard to pistons, there is still some diffe:ence of opinion as to the relative merits of cast-iron and aluminium. The advantages of the aluminium piston have been clearly demonstrated so far as the private car is concerned, but doubts still exist as to its suitability for general adoption in commercial vehicles. In this connection the writer desires to exclude from consideration the fleets of buses which are run under the special care of thoroughly well-organized establishments where trained men see to every upkeep need, but refers to the ordinary vehicle which usually comes in for a fair share of neglect and improper usage.

When one reads the advertisements of firms who make a speciality of filling up the grooves made in cylinders by gudgeon pins which have become loose, one wonders what attention can have been given to the methods of securing such pins, either by the makers in the first c40 place or by thOse who have reassembled the engine after overhaul. By the adoption of the now well-known methods of securing a gudgeon pin, "there should be no such word as fail." The type that has been gaining in favour is the spring ring, which can be inserted in a groove cut on the inside of the boss in the piston, the end movement of the gudgeon pin being thus limited.

The relative merits and demerits of the various methods of operating valves is a point which is still unsettled, each system of valve gear having certain advantages and disadvantages, none of them possessing sufficiently outstanding merits to have ousted the others.

There is, therefore, always safety in selecting the old plan of valve operation which everyone knows to work well and which everyone understands. In some cases the convenience of machining operations on the cylinder block seems to have been taken more into consideration than the convenience of the man who has to examine and grind-in valves from time to time.

The writer recently saw a valve which had been running for many years and was as good as new ; it was made of mild steel, case-hardened. It is curious that this material and treatment were not more generally followed.

There is little need to discuss engines to-day which have fewer than four cylinders, but the question arises whether six cylinders would not be an advantage for certain classes of commercial vehicles. The writer feels

that he will be laying himself open to criticism in suggesting the use of six cylinders for anything but luxury use, but experience of vehicles so fitted leads him to believe that such engines would find favour if used for buses and chars-h-bancs, and even for the heavier class ' of goods-carrying vehicles. It will be said that in the six-cylinder engine there are more details to look after, and that there are quite enough for an ordinary man at present. This is true, but it must be remembered that, with six cylinders doing the work instead of four, all working parts have less stressiand an easier time, and that, consequently, they will not require so much looking after. Apart from this, there is the smoother running, that would appeal strongly to the passengers carried.

For the heavier types of engine the man who is responsible for maintenance will always prefer cylinders east in pairs to those cast en bloc ; they are easier to handle in the garage, and should any accident happen, such as cracks through frost, they are cheaper to replace.

The fight between the therino-siphonic system of watercirculation and circulation by pump doe b not seem to have shown that any particular advantage was possessed by either system, In deference to the public fancy, many makers have fitted pumps or hustlers and abandoned the thermo-siphonic system. So far as cost of production goes, there is nothing between the two systems, as the cost of the pump is not very great, and it is more than covered by that of the larger pipes and radiator necessitated by the thermo-siphonic system.

Looked at from the point of the driver or man responsible for upkeep, the latter is the simpler, so long as the vehicle is intended for use in a temperate climate. The gland of a pump or hustler, no matter how well made, is always likely to give trouble on the road, and a loss of water is often the cause of cracked cylinders and delay.

A flat flange should always be fitted to some part of a water system, so that, should it be necessary to disconnect the radiator, there is no need to break the joint of the rubber hose, as this often results in damaging the hose so that it cannot be replaced, and spares are not always available in out-of-the-way places. A flat flange can always be fitted with a temporary washer that a driver can improvise on the road.

There is little doubt that the single-plate dry clutch is giving the greatest satisfaction to-day. The main factor which commends this class of clutch to users is that it requires practically no attention. If the clutch be faced with a fabric which requires to run in oil, a very sweet engagement can always be effected, for the oil acts as a cushion between the clutch faces.

The gearbox, although generally admitted to be one of the parts of a modern vehicle which i are most calling for improvement, seems to defy all efforts on the part of inventors to change it, In spite of the numerous designs which have from time to time been introduced, the common sliding type of gear is to be found in the gearbox on the majority of vehicles offered for sale to-day. Although this mechanism is far from perfect, as can he gathered by anyone who frequents repair shops, its simplicity of construction seems to endear it to the public.

The auestion as to how many gears should be provided—three or four—seems to have settled itself into three for vehicles under three tons load and four for heavier types, although unquestionably the tendency, if anything, is towards the use of a fourth gear.

The treatment of the steel for the teeth is still an open question—whether it should be case-hardened or airhardened. The former method gives the best results so far as resisting wear, but the resulting teeth are inclined to chip in the corners, whilst with the latter method there is less tendency to chip and the gears are therefore more durable.

Opinions are still divided as to the position of -the change-speed lever—whether it should be centrally disposed or be mounted at the right .side of the driver. For real rough work, where a chassis is likely to get a severe twist on uneven ground, the central lever has the advantage, as the side lever, unless designed with care, will in some cases become jammed through the distortion of the frame. Simplicity is undoubtedly on the side of the central position, and a compromise is to be found in extending the gear turret out to the side to act as a bearing for the gear-change shaft.

Where unit construction is adopted—that is to say, the engine and gearbox are made in one unit—there is no need for universal joints, as usually understood, between the two shafts. But "Where the gearbox and engine are separated it is essential that a flexible shaft should join the two, as frame distortion or -errors in alignment are then unavoidable. To meet this misalignment, it is essential that a short shaft should be provided with a universal joint where it couples to the engine and gearbox shafts, or a special form of universal joint should be fitted which can accommodate itself to parallel misalignment and not merely to errors of angle.

The fitting of only one universal of ordinary type in this position is not correct, but is the cause of much. trouble in the bearings of engines and gearboxes.

The universal joint which is most popular for this position is that class of coupling known as " Rag " disc.

For use behind the gearbox, however, one has to select a universal joint with much more care, as so many points have to be taken into consideration. Much will depend on the class of drive employed. One of the greatest difficulties the designer has had to encounter Is the design of a thoroughly efficient universal joint that will allow of a certain amount of sliding movement of the two shafts. The sliding block type is one of the

best, provided that it is designed on the principle of the unspillable ink bottle. Made in this form, it is oil retaining, as there should be no means of escape for the lubricant when once introduced into the join t. Providing that oil, not grease, is used. the parts should be in a continual bath of lubricant, a n d wear should be reduced to a mini

In the rear axle we come to a part of a vehicle in the design of which there is probably more difference of opinion than in any other component. 1ft is as well, however, to consider the advantages and disadvantages of all the known types, as it is oi little good to the intending purchaser to speculate.

The rack ring and pinion drive, which was common in the earlier days on the vehicles which then came from the Continent, has gradually declined in popularity. The Americans revived it to a certain extent, but American practice cannot always be taken as a criterion as to what is the best. The low platTorm bus recently introduced by the London General Omnibus Co., in which this form of drive is employed, is one of those examples where great care in design and skill on the part of the engineers has permitted the adoption of a device which, generally speaking, is not looked upon with favour. It has one desirable feature, in that it enabled them to build a chassis with a very low platform, and this secured its adoption.

Undoubtedly, this class of drive requires all parts to be most accurately adjusted and in perfect order if silence is to be obtained, and the writer very much doubts whether in ordinary hands such a drive could he relied upon to receive the skilled attention which it receives at the hands of the company who introduced it into the modern bus.

Very little can be said against that class of gear in which bevel gears are employed in conjunction with a second reduction gear, excepting that it entails a very great amount of the weight being mounted on an axle which is unsprung. Bad it not been for this undesirable feature, it would probably have ousted all other methods of driving a rear axle.

The worm drive, although it has fallen out of favour in the private car on account of its relatively low efficiency, is in a stronger position than ever as applied to the commercial vehicle. Although its efficiency may not be as high as could be desired, its extreme simplicity commends it to the user, as it makes the necessary reduction of speed in one bite instead of 4n two. Provided that it is well made, its wearing qualities are quite good enough to satisfy the average user. The fight between the parallel and the enveloping types of worm seems to have died down.

can be recommended.

Doubts have been expressed as to whether a worm situated above the worm wheel will get its fair share of lubricant. The writer recommends those who doubt this to remove the cover from the top of the worm box and to stand in the line of fire with a new suit of clothes on when the vehicle is travelling at a good pace, and he will soon alter his opinion.

It is proposed to deal with the surroundings of the rear axle, such as torque reds, torque tubes, radius rods, and the effect of torque on springs, as well as with lubrication, suspension, frame construction, and steering gears in a further article.