FROM COURSE TO COURSE BY MOTORVAN,

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How the Speed Merchant Transported his Racing Steed Through Three Counties and was not Discomfited Because he Captured no Cups.

A "TOUR DE FRANCE " of the most unusual char ti including excursions into Italy and Spain, was made by that indefatigable sportsman, Major E. A. D. Eldridge, in an heroic attempt to compete, with the same car, in three of the most important races in the European calendar. On August 17th last Mr. Eldridge annexed several 1,500 c.c. records, lapping Brooklands track at the astonishing speed of 114 m.p.h. These records were obtained with the single-seater Eldridge Special No. I. At this time the Eldridge Special No. II, a wonderful, underslung, streamlined two-seater, originally designed for the French Grand Prix, was nearing completion in Paris.

Immediately after obtaining the records at Brooklands, Mr. Eldridge decided to enter the new car for the Italian Grand Prix, the Spanish Grand Prix, and the Brooklands 200-Mile Race, and, distrusting the capabilities of the French railways, be made arrangements to transport his car to the different rendezvous by road.

This scheme involved a journey of some 2,000 miles or more. However, when once the decision had been taken, no time was lost. A Ford one-ton covered van was purchased and specially fitted up with a windlass and loading boards. Then, with the single-seater car iu the van, Eldridge and his two mechanics set out.

The mechanics, who should certainly be "mentioned In dispatches," were "Jim" Ames (who has been Eldridge's right-hand man for the past seven or eight years) and .1. King. The Channel was crossed via Newhaven and Dieppe, and Paris was reached on August 22nd. Here the single-seater car Special No. was unshipped, and the supercharged engine thereof, which had behaved so well at Brooklands, was changed over to the new two-seater car Special No. IL This engine transfer, and the final detail work on the car, involved a strenuous period of day-and-night labour for all concerned ; but at lak, only three days before the Italian race, all was ready, and a start was made from Paris on Thursday, September 3rd, at 8 am.

In view of the fact that the car had to be weighed in at M01123. 1,000 kilometres away on the Saturday morning, it was quite out of the question to put up for the night anywhere on the road, and, in spite of the fact that all hands had worked throughout the whole of the two preceding nights, a straight-through run had to be made to Italy.

In addition to its human freight of four fairly heavy men (for another passenger, Mr. H. Morgan, had been picked up in Paris), the Ford van bore the following burden :—A racing car weighing -131 cwt., 3 cwt. of tools and tyres, 3 cwt. Of spare parts, four spare wheels for the racing car, four spare wheels for the van, 100 gallons of special petrol in drums, and three five-gallon drums of Castrol, and sundry suitcases and personal luggage.

With all this freight on board, the van load was not "one ton," but very nearly two. From Paris a direct route was taken via Melun, Auxere, Chalon-sur-Saone, Bourg and Charnbery. The evening of the second clay (Friday) saw the Ford struggling slowly up the Mont Cents pass under its preposterous burden. When apparently near the top of the pass a stop was made to fill up with water from one of the mountain streams. The gradient at this point was steep, and after having its radiator filled the Ford decided that it was tired, if no one else was, and firmly refused to restart up the bill.

The outlook was not encouraging; darkness was falling and it was already getting intensely cold. Moreover, not only is the Mont Cenis an entirely unsuitable place whereon to spend the night, but there seemed little chance of getting to Monza the next morning for the weighing in. Mr. Eldridge suggested that the other members of the party should push behind whilst he drove the van to the top of the pass, which, he was sure, was only a few minutes' walk away. Actually, it turned out to be another 14 kilometres! However, in the midst of the argument a big American lorry came in sight, run fling down the hill. The driver of this vehicle proved an excellent sportsman. He turned his lorry round and towed the Ford to the top of the pass.

The run down into Italy was made in the growing darkness, and Mr. Eldridge evidently decided in his mind that this Mountain road, with its countless hair-pin bends on the edge of 1,000-ft. cliffs, offered a fine opportunity to get in a little practice work in fast cornering. His passengers were not at all of the same opinion, and their shrieks woke the echoes the whole way down the pass.

Turin as passed through during the night, and Milan reached just before daybreak on Saturday morning, the party finally arriving at Monza trackat 7 a.m., the through journey from Paris having taken exactly 49 hours.

International Grand Prix races in , these days involve a considerable physical strain for the drivers, and a certain period of training is recommended. On this occasion, however, Mr. Eldridge declared that he felt sufficiently "trained," and he dispensed with the usual series of physical exercises.

When the race actually started, the Eldridge Special got away in. excellent style, but on the second lap clutch trouble developed, and the car had to be withdrawn. On examination, the clutch lining was found to have crumpled up into a sort of pudding.

The night afteethe race was spent in Monza, where the party at last went to bed.' The next afternoon (Monday) Milan was reached. Here, in a small garage, the car was overhauled, four days' work being spent on it. On Saturday, September 12th, a start was made for San Sebastian.

One member of the party—Mr. Morgan—had returned to Paris by train, but, in order that the Ford van should not be lacking in ballast, his place was taken by M. de Backer, a commissaire of the Automobile Club of France.

The Riviera was reached via Asti, Cuneo, the Col de Tande, and Ventimille, an unsuccessful attempt being made to take a short cut over the Col de 13raus. At the foot of it an aged peasant shouted something as the Ford went past. "Try not the pass„'! the old man said, in all probability, but no one could hear him. So, like the foolish young fellow in the poem, who carried a flag in a snowstorm, the party proceeded upwards for several miles until they got stuck on a gradient of about 1 in 33-.

This meant turning back, and involved a double crossing of the frontier before Nice could be reached.

Complications arose with the Customs people, but these were soon smoothed out in the usual manner. The Col de Tande had to be negotiated after dark—a rather dangerous proceeding—and Nice was reached between 10 and 11 p.m. A night was spent in Nice, and the next day Toulouse was reached via Aix en Provence, Montpellier and Carcassonne. This portion of the 'journey was comparatively enjoyable. The warm southern sunshine cheered the hearts of the company, whilst delightful meals of grapes and.

peaches were obtained (for the taking !) when passing through the vineyards and orchards of Provence.

After spending a night in Toulouse, the last. part of the trip was accomplished in one long stage from Toulouse to San Sebastian, which was reached early on Thursday morning, September 17th.

The Spanish Grand Prix was held on. the Saturday. Unfortunately, Mr. Eldridge's. streak of bad luck had followed him from Italy to Spain, and after three laps of the course similar clutch trouble again caused his retirement. Mr. Eldridge is an excellent loser, however, and no amount of ba.d luck upsets this cheery sportsman.

Immediately after the race the light car was once

again put on board the van and a start was made on Sunday afternoon for Paris, with a view to dashing across to Brooklands, if possible, in time to compete in the 200-Mile Race. Dax SAMS reached that night via Bayonne. Here the consistently fine weather experienced throughout the trip at last broke, and the rain attempted to make up several weeks of arrears in a few hours.

Whether it was the load or the fact that everyone was beginning to feel the strain rather badly, one cannot say, but, from Dax onwards, the average speed began to drop. A short run in atrocious weather was made from Dax to Bordeaux, where another night was spent. The next stage was to Poitiers, and the final one to Paris via Chartres. By the time Paris was reached it was already evident that there would be no time to prepare for the 200-Mile Race, and Mr. Eldridge reluctantly gave up the idea, and he and his exhausted band of heroes took a well-earned rest in Paris instead.

This short account of the trip gives but little idea of

what a really strenuous affair it was. Since Mr. Eldridge's return to Paris the writer has sampled the comforts of the Ford with the racing car on board, and how anyone could have stood it day and night for over. 2,000 miles passes comprehension.

All members of the party took turns at enjoying the "sleeping accommodation." This was the space between the sides of the racing car and the side boards of the van. It was almost entirely filled with spare wheels, cans, and toolboxes.

The racing car swayed continually under the move ment of the van, straining at its lashings and threatening to crush the wretched passengers, who sat or crouched amongst the junk on each side of it. Over the rough French roads the nol,se inside the van was incredible.

• Everything seemed to work loose, and, in spite of the restricted space, spare wheels and big oil drums banged about and continually smote the inside Passengers in new and unexpected places. The crashing of the cans, the jingling of the tools and spare parts, the screams of the injured, and the shouts of those expecting to be injured made -pandemonium!

NOT MANY weeks ago we were able to give exclusive and comprehensive details of a Karrier rigid six-wheeler of the semi-bogie type, and we published pictures showing the extraordinary flexibility of this machine in travelling over extremely rough ground and surmounting high obstacles.

So successful were the results obtained with this multi-wheeler that the makers decided immediately to turn their attention to the design and construction of a much bigger and more powerful model which would be suitable for passenger vehicles of large capacity, and they have now produced a chassis suitable for double-deck bus bodies seating approximately 50 persons and saloon coaches for 30 persons.

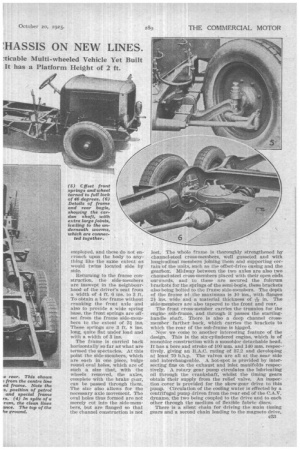

This chassis is almost revolutionary in its design. And every credit should be given to its makers for their Initiative in setting a lead to other British makers in a movement which, • we are certain, will soon be of a far-reaching nature. We inspected the drawings of this chassis some two months ago, and were at once greatly impressed by its potentialities and the novel points in its construction, together with the fact that, without cranking the frame, it has been found possible to provide a frame height loaded of 1 ft. 11 ins, and a body platform height of 2 ft. only.

Other makers have drawn our attention to a statement regarding the small difference between the frame level and the platform level, which we made in connection with the smaller model, and it was even suggested that it would be quite impossible to build a body so low on the chassis. If this be so, then Karrier Motors, Ltd., have achieved the impossible—and have done so in a very interesting manner.

Along the side-members of the frame are light, pressed-steel brackets, eact with a step at its outer e32

end, into which fit the longitudinal runners of the body. These brackets are inswept from the top to the base, and form supports for the body pillars. The 1-in, boards forming the floor of the body thus ride acress the frame, and are even recessed on their lower faces to take the rivet heads of the frame.

It has been realized by the makers that it is only going half-way towards the lowPlatform vehicle if the usual allowance has to be made for the movement of the centre of an axle casing. Therefore, they decided to move the whole drive line to the side of the chassis, the off side being selected because the extra weight imposed at this side is, to a certain extent, balanced. by the weight thrown to the near side owing to road camber. The actual extent of the offset is 1 ft. 1g, ins, from the centre line of the chassis, and this brings the axle centres conveniently under the bus seats.

Another advantage of the semi-bogie arrangement is that single pneumatic tyres can be employed, and these do not encroach upon the body to anything like the same extent as would twins located side by side.

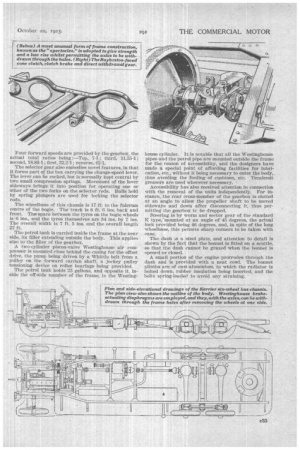

Returning to. the frame construction, the side-members are inswept in the neighbourhood of the driver's seat from a width of 4 ft. 6 ins. to 3 ft. To obtain a low frame without cranking the front axle and also to provide a wide spring base, the front springs are offset from the frame side-members to the extent of 3.i ins. These springs are 3 ft. 8 ins, long, quite flat under load and with a width of 3 ins.

The frame is carried back horizontally so far as what are termed the spectacles. At this point the side-members, which are each in one piece, bulge round oval holes, which are of such a size that, with the wheels removed, the axles, complete with the brake gear, can be passed through them. The size also allows for the necessary axle movement. The oval holes thus formed are not merely cut into the side-members, but are flanged so that the channel construction is not lost. The whole frame is thoroughly strengthened by channel-steel cross-members, well gusseted and with longitudinal members joining them and supporting certain of the units, such as the offset-drive casing and the gearbox. Midway between the two axles are also two channel-steel cross-members placed with their open ends outwards, and to these are secured the fulcrum brackets for the springs of the semi-bogie, these brackets also being bolted to the frame side-members. The depth of the frame at the maximum is 10 ins., with flanges 24 ins, wide and a material thickness of * in. The side-members are also tapered to the front and rear.

The front cross-member carries the trunnion for the engine sub-frame, and through it passes the startinghandle shaft. There is also a deep channel crossmember farther back, which carries the brackets -to which the rear of the sub-frame is hinged.

. Now we come to another interesting feature of the design. This is the six-cylindered engine, which is of monobloc construction with a monobloc detachable head. It has a bore and stroke of 100 mm. and 140 mm..respectively, giving an R.A.C. rating of 37.2 and developing at least 70 b.h.p. The valves are all at the near side and interchangeable. A hot-spot is provided by intersecting fins on the exhaust and inlet manifolds respectively. A rotary gear pump circulates the lubricating oil through the crankshaft, whilst the timing gears

• obtain -their supply from the relief valve. An inspection cover is provided for the skew-gear drive to this pump. Circulation of the cooling water is effected by a centrifugal pump driven from the rear end of the C.A.V. .dynamo, the two being coupled to the drive and to each other through the medium of flexible fabric discs.

There is a silent chain for driving the main timing gears and a second chain leading to the magneto drive,

the magneto being mounted on a separate bracket above the dynamo. Cooling is assisted by an eccentrically mounted fan driven by a link belt from a pulley at the front of the dynamo drive. An accessible filter is situated close to the oil inlet on the timing ease at the near side.

To avoid difficulties with mixture distribution, two carburetters are fitted, each supplying three cylinders.

Aluminium castings are employed for the gilled tube radiator, a thermostat being incorporated in the inlet connection between cylinders and heailer.

The flywheel is open, and to it is bolted a starterring, the C.A.V. starter itself being bracketed to the near side of the sub-frame, one of its bolts serving also to secure one side of a forked plate stretching across the sub-frame and carrying the Raybestos clutch stop.

A pressed-steel centre is employed for the external 'cone clutch, Which is faced with special Raybestos. There is no cross-shaft and the withdrawal mechanism is both neat and unusual. The withdrawal lever, which acts direct on a ball thrust, is carried on a vertical pin fulcrumed in a bracket on the sub-frame, a second lever underneath this bracket being connected to the clutch pedal by a ball-ended adjustable rod.

Immediately behind the withdrawal gear is a rubberproofed fabric joint. At this point the drive is taken across to the off-side cardan shaft leading to the gearbox by a self-adjusting, silent chain totally enclosed in a neat cast-aluminium housing with a full-size cover for inspection. This housing is supported, as mentioned previously, by a longitudinal frame member at one end and pivoted on a frame bracket at the other. By removing four bolts, the whole casing can be shifted sideways until it is released from the driving splines on the clutch shaft, when it can be dropped.

The chain adjustment, just referred to, consists of a spring steel plate held up against the slack side of the chain by means of a light spring and bell-crank lever.

The joints On the forward cardan shaft are also rubberized fabric.

The gearbox itself is three-point suspended by a trunnion at the front end and by a cast-steel crossmember at the rear end, this also forming an anchorage for the Contracting shoes of the transmission brake, which are lined with Raybestos. The shoes are operated by a bell-crank lever with an accessible hand adjustment underneath.

Owing to the angularity of the propeller shaft, it has been thought advisable to utilize joints of generous size. These are of the Hookes type, with roller bearings, each joint, complete with its bearing, being entirely of 'Carrier make. A sliding splined joint is provided at the front end, and there is a tubular shaft between them, whilst the joints, apart from being enclosed in themselveS, are 'additionally protected by spring-held spherical covers, and a leather bellows protects the plunger joint.

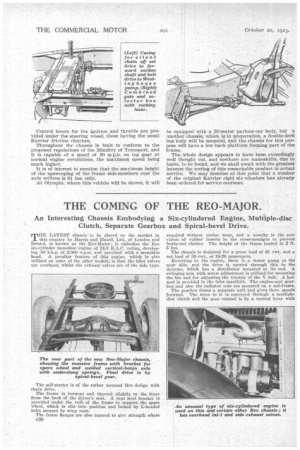

The drive is taken first to the underneath worm of the forward of the two driving axles and then from the tail end of this worm shaft to the worm of the second driving axle, the gear ratios of the axles being 7-1. Each axle casing forms a horizontal banjo built up of pressed-steel halves welded together in the horizontal plane and having, at its ends, brake anchorages supporting the Westinghouse brake-actuating diaphragms, these anchorages also being welded on and carrying the spring shackle pins.

We do not propose to enter fully into the details of the semi-bogie construction, as, except for the omission of the reduction gear and the offsetting of the casing, the general design is similar to that of the first Karrier six-wheeler, light but effective radius rods being provided between the two axles, these being ball-jointed and mounted above the springs, the springs themselves being inverted semi-elliptics pivoted on the brackets to Which we have already referred. The spring' centres are 4 ft. apart and the springs have a width of 4 ins.

The wheels run on taper-roller bearings, and the brake shoes expand in 15-in, drums, the friction fabric being held to the shoes by T-heated bolts in the manner with which users of Karrier vehicles are familiar.

Four forward speeds are provided by-the gearbox, the actual total ratios being :—Top, 7-1; third, 1t55-1; second, 18.83-1; first, 32.2-1; reverse, 42-1.

The selector gear also embodies novel features, in that it forms part of the box carrying the change-speed lever. The lever can be rocked, but is normally kept central by two small compression springs. Movement of the lever sideways brings, it into position for operating one or Other of the two forks on the selector rods. Balls held by spring plungers are used for locking the selector rods.

The wheelbase of this chassis is 17 ft. to the fulcrum centre of the bogie. The track is 6 ft. 6 ins, back and front. The space between the tyres on the bogie wheels is 6 ins., and the tyres themselves are 34 ins. by 7 ins. The overall width is 7 ft. 5 ins, and the overall length 27 ft.

The petrol tank is carried inside the frame at the near side, its filler extending outside the body. This applies also to the filler of the gearbox.

A two-cylinder piston-valve Westinghouse air compressor is mounted close behind the casing for the offset drive, the pump being driven by a Whittle belt from a pulley on the forward cardan shaft, a jockey pulley tensioning device on roller bearings being provided.

The petrol tank holds 25 gallons, and opposite it, inside the off-side member of the frame, is the Westing house cylinder. It is notable that all the Westinghouse pipes and the petrol pipe are mounted outside the frame for the reason of accessibility, and the designers have made a special point of affording facilities for lubrication, etc., without it being necessary to enter the body, thus avoiding the fouling of cushions, etc. Tecalemit greasers are used wherever necessary.

Accessibility has also received attention in connection with the removal of the units independently. For instance, the rear cross-member of the gearbox is slotted at an angle to allow the propeller shaft to be moved sideways and down after disconnecting it, thus permitting the gearbox tc be dropped.

Steering is by worm and sector gear of the standard K type:Mounted at an angle of 45 degrees, the actual lock provided being 46 degrees, and, in spite of the long wheelbase, this permits sharp corners to be taken with ease.

The dash is a steel plate, and attention to detail is shown by the fact that the bonnet is fitted on a scuttle, so that the dash cannot be grazed when the bonnet is opened or closed.

A small portion of the engine protrudes through the dash and is provided with a neat cowl. The bonnet plinths are of cast-aluminium, to which the radiator is bolted down, rubber insulation being inserted, and the bolts spring-loaded to avoid any straining. Control levers for the ignition and throttle are provided under the steering wheel, these having the usual Karrier friction clutches.

Throughout the chassis is hbilt to conform to the proposed regulations of the Ministry of Transport, and it is capable of a speed of 30 m.p.h. on top gear at normal engine revolutions, the maximum speed being much higher.

It is of interest to mention that the maximum height of the upsweeping of the frame side-members over the axle orifices is 3-1 ins. only.

At Olympia, where this vehicle will be shown, it will

be equipped with a 26-seater parlour-car body, but n. another chassis, which is in preparation, a double-deck bus body will be mounted, and the chassis for this purpose will have a low back platform forming part of the frame.

The whole design appears to have been exceedingly well thought out, and nowhere are makeshifts, due to haste, to be found, and we shall await with the greatest interest the testing of this remarkable product in actual service. We may mention at this point that a number of the original Karrier rigid six-wheelers has already been ordered for service overseas.