BUILDING VANS 0 MOVING PLATFORM

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

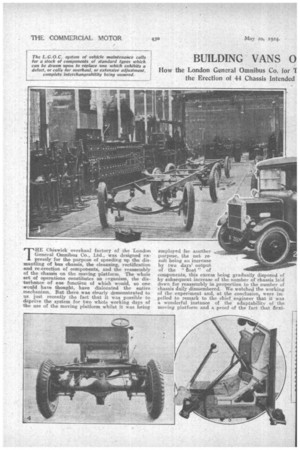

RE Chiswick overhaul factory of the London • General Omnibus Co., Ltd., was designed ex

pressly for the purpose of speeding up the dismantling of bus chassis, the cleansing, rectification and re-erection of components, and the reassembly of the chassis on the moving platform. The whole set of operations constitutes an organism, the disturbance of one functi,ni of which would, so one would have thought, have dislocated the entire mechanism. But there was clearly demonstrated to us just recently the fact that it was possible to deprive the system for two whole working days of the use of the moving platform whilst it was being employed for another purpose, the net result being an increase by two days' output of the " float " of components, this excess being gradually disposed of by subsequent increase of the number of chassis laid down for reassembly in proportion to the number of chassis daily dismembered. We watched the working of the experiment and, at the conclusion, were impelled to remark to the chief engineer that it was a wonderful instance of the adaptability of the moving platform and a proof of the fact that flexi

billy had not been sacrificed in devising a system of chassis overhaul which would at first sight appear to be quite.inflexible. Yet even more interesting still was -the particular reason for thus depriving the overhaul systena of the services of the moving platform for two days. There had been designed a 15-cwt. van, the whole of the component parts were ready and in stock and it was desired to complete their erection into chassis form with no delay whatever, because • the body builders were ready to commence work upon the • completion of the vehicles.

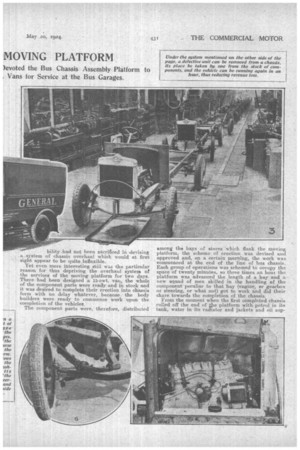

The component parts were, therefore, distributed among the bays of stores -which flank the moving platform, the scheme of erection was devised and approved and, on a certain morning, the work was commenced at the end of the line of bus chassis. Each group of operations was schemed to occupy the space of twenty minutes, so three times an hour the platform was advanced the length of a bay and a, new squad of men skilled in the handling of the component peculiar to that bay (engine, or gearbox or steering, or what not) got to work and did their share towards the completion of the chassis. From the moment when the first completed chassis rolled off the end of±jie platform with petrol in its Lank, water in its radiator and jackets and oil sup

plied to the moving parts, a replica emerged. every twenty minutes, so that, at the end of the working day, about 20 of the chassis had. been produced. On the resumption of work the next day the output continued at the same rate; but, -of course, the first of the day's batch " passed oft the platform within a few minutes, and so the last of the desired total of 44 chassis was clear of the platform before the works closed down that day.

Every, chassis as it left the platforin was taken in hand by a tester and put through its paces over the testing ground that surrounds the works. Any observed departures • from the standard laid down Were carefully noted on a card and the chassis passed into the running shed for rectification and was then again handed over to the tester, who proceeded to check these corrections and to prove brakes and engine power on the decline and incline, With their steep grades of I in 15, which have been

formed as a bypass from the. road in front of the factory. .

So soon-as each chassis had received the approval of the inspecting staff, it was despatched to the body builders to be equipped with a smart van body. The bonnet bears a cast aluminium plate with the type letter V and the individual number of the chassis. This clearly appears in one of our views— that of the completed van bearing the symbol VI.

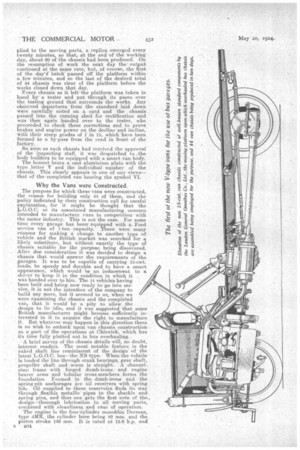

Why the Vans were Constructed.

The purpose for which these vans were constructed, the reason for building only 44 of them, and the policy indicated by their, construction call for careful

explanation, for it might be thought that the L.G.O.C. or its associated manufacturing concern intended to manufacture vans in competition with the motor industry. This is not the case. For some tirne every garage has been equipped. with a Ford. service van of 1-ton capacity. There were many reasons for making a change to another type of vehicle and the British market was searched for a likely substitute, but without exactly the type of chassis suitable for the purpose being discovered. After due consideration it was decided to design a chassis that would answer the requirements of the garages. It was to be capable of caryying 15-cwt. loads, be speedy and durable and to have a smart appearance, which would bp an inducement to a driver to keep it in the condition in which it was handed over to him. The 44 vehiele's having been built and being now ready to "go into service,it is not the intention of the company to build any more, but it seemed to us, when we were examining the chassis and the completed van, that it would be a pity to allow the design to lie idle, and it was suggested that some British manufacturer might become sufficiently interested in it to acquire the right to manufacture it. But whatever may happen in this direction there is no wish to embark upon van chassis construction as a part of the operations at Chiswick, which has its time fully plotted out in bus overhauling.. A brief survey of the chassis details will, no doubt, interest readers. .The most notable feature is the raked shaft line reminiscent of the design of the latest L.q.o.C. bus—the NS type. When the vehicle is loaded the line through crank bearings, gear shaft, propeller shaft and ,worm is straight. A channelsteei frame with forged dumb-irons and engine bearer arms and tubular cross-members forms the foundation. Formed in the dumb-irons and the spring-pin anchorages are oil receivers with spring lids. Oil supplied to these reservoirs finds its way through flexible metallic pipes to the shackle and spring pins, and thus one gets the first note of the design—thorough lubrication to all moving parts, combined with cleanliness, and ease of operation.

The engine is the four-cylinder inonobloc Dorman, type .4MR, the cylinder bore being 80 mm. and the, piston stroke 130 Om. It is rated at 15.9 h.p. and s B34 develops 27 h.p. at 1,600 r.p.m. Lubrication is effected by pressure to the main bearings and by trough supply to dippers on the bearing caps which lubricate the cylinder walls. The petrol caps, is mounted at the rear of the dashboard, the cast aluminium brackets supporting the dashboard being provided with steel straps to .carry the tank. The petrol passes through a three-way cock (in one position the reserve supply is turned on) to an Autoklean filter mounted on the engine side of the dash and thence to a Solex carburetter through a flexible metallic pipe, the carburetter control being connected up to the accelerator pedal. The Lucas flange-fitting magneto is mounted on a bracket. at the near side of the engine, and the crankcase oilfilling orifice opposite the rear-valve tappet cover plate. The inlet and exhaust pipes are held by dogs and are readily removable, whilst easy access is given to the valve -tappets and springs on the removal of the cover plates.

Driven by Whittle belt, the C.A.V. dynamo is mounted on the off side of the engine, whilst the fan, in an adjustable mounting, and the pump are driven by the same type of belt. The radiator is supported in trunnion bearings and is very clean in its design. The standard radiator guard mounted on the dumb-irons is employed.

The power is taken through an ordinary leatherfaced cone clutch having a cup and cone clutch stop, and through a double Hardy flexible joint to the gearbox, which is slung at four points from two of the tubular cross-members, the gear-lever shaft being carried in a turret and taken to the outside of the frame, se that the gear and brake levers are at the driver's right hand. The gearbox is constructed by Greenwood and Batley to Dux patents and gives four forward speeds and reverse. The gears are in constant mesh, engagement being effected through dogs. The whole of the gearing is of very robust construction, the shafts being short and the bearings large. The propeller shaft is enclosed, and it transmits the drive to a reversed Kirkstall worm-driven axle, the tension strains being taken by the worm cover. The front axle is also of Kirkstall manufacture. Long semi-elliptic springs are employed, and every spring and shackle pin has its oiler. The wheels are of east aluminium, having eight spokes well webbed, the registered design of which has been devised so that the metal after the casting will contract evenly. The wheels are provided with steel discs and are shod with Beldam pneumatic tyres '765 mm. by 105 mm. on the front and with Gable tyres 130 mm. for 26-in, rims for the rear. All the brakes operate on the rear wheels.

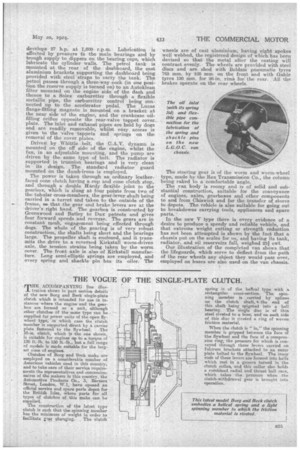

The steering gear is of the worm and worm-wheel type, made by the Rex Transmission Co., the column being raked to a comfortable angle. The van body is roomy and is of solid and substantial construction, suitable for the conveyance of eugiees, axles, gearboxes and other components to and from Chiswick and for the transfer of stores to depots. The vehicle is also suitable for going out to breakdowns carrying tools, appliances and spare parts.

In the new V type there is every evidence of a desire to produce a speedy and reliable vehicle, and that extreme weight cutting or strength reduction has not been attempted is shown by the fact that a chassis put on the scales for us, and having its tank, radiator, and oil reservoirs full, weighed 23,1 cwt.

Our illustration of the completed van shows that the lifeguards, which serve to deflect from the path of the rear wheels any object they would pass over, employed on buses are also used on the van chassis.