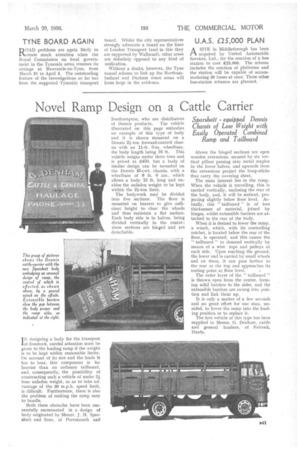

Novel Ramp Design on a Cattle Carrier

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

IN designing a body for the transport of livestock, careful attention must he given to the loading ramp if the weight is to be kept within reasonable limits. On account of its size and the loads it has to bear, this component is far heavier than an ordinary tailboard, and, consequently, the possibility of constructing such a vehicle of under 2i tons unladen weight, so as to take advantage of the 30 m.p.h. speed limit, is difficult. Furthermore, there is also the problem of making the ramp easy to handle.

Both these obstacles have been successfully surmounted iti a design of body originated by Messrs. J. H. Sparshatt and Sons, of Portsmouth and

Southampton, who are distributors of Dennis products. The vehicle illustrated on this page embodies an example of this type of body and it is shown mounted on a Dennis 2i-ton forward-control chassis with an 11-ft. 6-in, wheelbase, the body length being 16 ft. This vehicle weighs under three tons and is priced at £450, but a body of similar design can be mounted on the Dennis 45-cwt. chassis, with a wheelbase of 9 ft. 6 ins., which allows a body 13 ft. long and enables the unladen weight to be kept within the 2i-ton limit.

The bodywork ma Y be divided into five sections. The floor is mounted on bearers to give sufficient height to clear the wheels and thus maintain a flat surface. Each body side is in halves, being divided vertically in the centre; these sections are hinged and are detachable. Above the hinged sections are open wooden extensions, secured by six vertical pillars passing into metal staples in the lower halves, and upwards from the extensions project the hoop-sticks that carry the covering sheet.

The main interest lies in the ramp. When the vehicle is travelling, this is carried vertically, enclosing the rear of the body, and, it will be noticed, projecting slightly below floor level. Actually, this" tailboard" is of two thicknesses of material, joined by hinges, whilst extensible barriers are attached to the rear of the body.

When it is desired to lower the ramp, a winch, which, with its controlling ratchet, is located below the rear of the floor, is operated, and this causes the " tailboard " to descend vertically by means of a wire rope and pulleys at each side. Upon reaching the ground, the lower end is carried by small wheels and on these, it can pass farther to the rear as the top end approaches its resting point at floor level.

The outer layer of the " tailboard " is thrown open from the centre, forming solid barriers to the sides, and the extensible barriers are swung into position and link them up.

It is only a matter of a few seconds and no great effort for one man, unaided, to lower the ramp into the loading position or to replace it.

The first vehicle of this type has been supplied to Messrs. G. Denham, cattle and general hauliers, of Fa iroak, Hants.