SUCTION GAS IN ACTUAL RUNNING.

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Practical Road Experience with Col. D. J. Smith's Plant.

IT IS REMARKABLE how entirely one can. become oblivious to the fact that one is using suction gas when actually running on the road. We have had one or two trips on the Be'size lorry which is fitted with Colonel Smith's device, and that is the feature which most strongly impressed us. There are, of course, one or two little difficulties, such as are inseparable from any new departure. They occur in connection generally with the starting up of the plant. These are, undoubtedly, as we nave assured ourselves, merely mechanical faults in the present equipment, which is experimental, and which it was the inventor's intention to have long ago I replaced had he been able to get the necessary facilities to manufacture new ones. On the whole, we are inclined to view suction gas as an important and practical fuel for heavy vehicles.

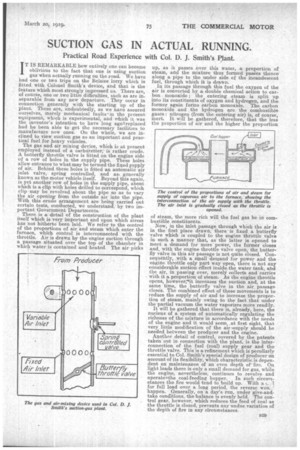

The gas and air mixing device, which is at present employed instead of a earburetter, • is rather crude. A butterfly throttle valve is fitted on the engine side of a roW of holes in the supply pipe. These holes allow entrance to what may be termed the fixed pupply of air. Behind these holes is fitted an automatic air inlet valve, spring controlled, and as generally known as the motor vehicle itself. Beyond this again, is yet another row of holes in the supply pipe, about which is a clip with holes drilled to correspond, which clip-may be revolved about the pipe so as to vary the air opening from the outside air into the pipe. With this crude arrangement are being carried out certain tests, conducted, we understand, by two important Government Departments. There is a detail of the construction of the plant itself which is very important and upon which stress has not hitherto been laid. We refer to the control of the proportions of air and steam which enter the furnace, which control is interconnected with the throttle. Air is drawn by the engine suction through a passage situated over the top of the chamber in which water is contained and heated. The air picks up, as it passes over this water, a proportion of steam, and the mixture thus formed passes thence along a pipe to the under side of the incandescent fuel, through which it is drawn. In its passage through this fuel the oxygen of the air is converted by a double chemical action to carbon monoxide ; the entering steam is split up into its constituents of oxygen and hydrogen, and the former again forms carbon monoxide. The carbon monoxide and the hydrogen are the combustible gases : nitrogen (from the entering air) is, of course, inert. It will be gathered, therefore, that the less the proportion of air and the higher the proportion of steam, the more rich will the fuel gas be in combustible constituents.

Now, in the inlet passage through which the air is in the first place drawn, there is fixed a. butterfly valve which is coupled to the engine throttle valve in such a manner that, as the latter is opened to meet a demand for more power, the former closes and, with the engine throttle valve open, the butterfly valve in this air passage is not quite closed. Consequently, with a small demand for power and the engine throttle only part way open, there is not any considerablesuction effect inside the water tank, and. the air, in passing over, merely collects and carries with it a proportion of steam. As the engine throttle opens, howeverit increases the suction and, at the same time, the butterfly valve in the air, passage closes. The combined effect -of these movements is to reduce the supply of air and -to increase the proportion of steam, mainly owing to the fact that under the partial vacuum the water vaporizes more readily.

It will be gathered that there is, already, here, the nucleus of a system of automatically regulating the richness of the mixture in accordance with the needs of the engine and it would seera„at first sight, that very, little modification of the air %supply should be needed between the producer and the engine.

Another detail of 'control, covered by the patents

takenOut in connection with the plant, is the interconnection of the fuel (coal) supply gear and the throttle valve. This is a refinement which is peculiarly essential to Col. Smith's special design of producer on account of its flexibility, which characteristic is dependent on maintenance of an even depth of fire. On light loads there is only a small demand for gas, while the engine, nevertheless, continues to revolve and operate4he coal-feeding hopper. In such circumstances the fire would tend to build DD. With at_ 1 for full load over a long period, the reverse wou,..' happen. Generally, on a day's run, under give-andtake conditions, the balance is evenly held. The control gear, however, which reduces the feed of coal as the throttle is closed, prevents any undue variation of the depth of fire in any circumstances.