HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

698.—A Cause of Big-end Trouble.

When fitting big-ends it is most important that the dowel pin in the liner should be shorter than the depth of the hole drilled in the connecting rod, otherwise serious trouble will certainly ensure, for, should the dowel pin be slightly longer than the hole, after a short time the hammering action to which the bearing is subjected will loosen the liner and give it a slight turning motion as well as up and down slackness. This will either cut a groove in the outside of the upper line or force the hearing to cave in and probably obstruct the oil channel.

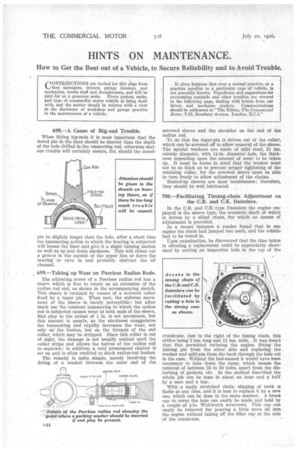

699.—Taking up Wear on Peerless Radius Rods.

The adjusting screw of a Peerless radius rod has a sleeve which is free to rotate on an extension of the radius rod end, as shown in the accompanying sketch. This sleeve is retained by means of a screwed collar fixed by a taper pin. When new, the endwise movement a the sleeve is barely perceptible ; but after much use the constant hammering to which the radius rod is subjected causes wear at both ends of the sleeve. End play to the extent of in. is not uncommon, but this amount is unsafe, as the slackness exaggerates the hammering and rapidly increases the wear, not only on the bushes, but on the threads of the end collar, which may be stripped. Since this collar is out of sight, the damage is not usually noticed until the collar strips and allows the halves of the radius rod to separate ; in addition, a very pronounced chatter is set up and is often credited to slack radius-rod bushes.

The remedy is quite simple, merely involving the fitting of a washer between the outer end of the screwed sleeve and the shoulder on the end of the radius rod.

To do this the taper-pin is driven out of the collar, which can be screwed off to allow removal of the sleeve. The special washers are made of mild steel, 2-6 ins.

outside diameter, with diameter hole, the thickness depending upon the amount of wear to be taken up. It must be borne in mind that the washer must not be so thick as to prevent proper tightening of the retaining collar, for the screwed sleeve must be able to turn freely to allow adjustment of the chains.

Rusted-up sleeves are most troublesome ; therefore, they should be well lubricated.

700.—Facilitating Timing-chain Adjustment on the C.B. and C.K. Daimlers.

In the C.B. and 0.1(.-type Daimlers the engine employed is the sleeve type, the eccentric shaft of which is driven by a silent chain, for which no means of adjustment is provided.

In a recent instance a reader found that in one engine the chain had jumped two teeth, and the vehicle had to be towed in.

Upon examination, he discovered that the time taken in effecting a replacement could be appreciably shortened by cutting an inspection hole in the top of the crankcase, just to the right of the timing chain, this orifice being 2 ins, long and 1+ ins. wide. It was found that this permitted retiming the engine, fitting the joining pin from the other side and replacing the washer and split-pin from the back through the hole cut in the case. Without the last-named it would have been necessary to take down the sump, which means the removal of between 25 to 30 bolts, apart from the disturbing of gaskets, etc. In the method described the whole job can be done in about an hour and a half by a man and a boy.

With a badly stretched chain, slipping of teeth is liable at any time, and it is best to replace it by a new one, which can be done in the same manner. A brass cap to cover the hole can easily be made and held by a couple of fin. Whitworth setscrews. This cap can easily be removed for pouring a little more oil into . the engine without taking off the filler cap at the side of the crankcase.