THE 30 CWT. MARATHON CHASSIS.

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

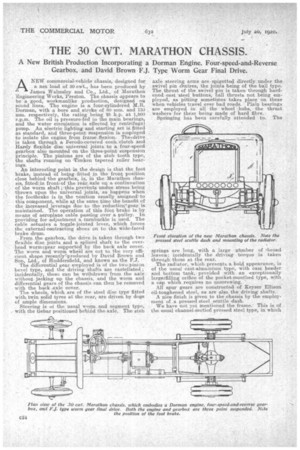

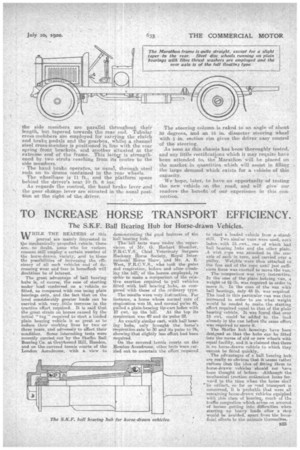

A New British Production Incorporating a -Dorman Engine, Four-speed-and-Reverse Gearbox, and David Brown F.J. Type Worm Gear Final Drive.

A NEW commercial-vehicle chassis, designed for a net load of 30.evit., has been produced by James Wahnsley and Co., Ltd., of Marathon Engineering Works, Preston. The chassis appears to be a good, workmanlike production, designed on sonnd lines. The engine is a four7cylindered M.R. Dorman, with a bore and stroke of 80 mm. and 130 mm. respectively, the rating being. 28 h.p. at 1,500 r.p.m. r.Che oil is pressure-fed to the main bearings, and the water circulation is effected by. centrifugal pomp. An. electric lighting.and starting set is.fitted as standard, and three-point suspensien is employed to isolate the engine from frame,flexion. The:drive is taken through a Ferodo-covered conb, clutch and Hardy flexible disc universal joints to a four-speed gearbox also mounted on the three-point suspension principle. The pinions are of the stub tooth type, the shafts running on •-TimIceri tapered roller bearings.

An interesting point in the design is that the foot brake, instead of being-fitted in the front position close behind the gearbox, is, in the Marathon chassis, fittedlin frontef the rear, axle on a continuation of the worm shaft ;:this.prevents: undue. stress being thrown upon the universal joints, as happens when the footbrake is in the nesition usually assigned.' to this component, while a,t the same time the benefit of the increased leverage due to the reductions'gear is maintained. The operation of this foot brake is by means of aeroplane cable passing over a pulley. In providing for adjustment a turnbuckle is used. The cable actuates a toggle-jointed lever, which forces the external-contra,cting shoes on to the wide-faced brake drum.

From the gearbox, the drive is taken through two flexible disc joints and a. splined shaft to the overhead wormfgear supported by the back axle cover. The worm and worm wheel are out to the very efficient shape recentlyproduced by David Brown and Son, Ltd., of Huddersfield, and known as the F.J. The differential gear employed is of the two-pinion bevel type, and the driving shafts are castellated ; incidentally, these can be withdrawn from the axle without jacking up the chassis, and the worm and differential gears of the chassis can then be removed with the back -.axle cover.

The wheels, Whieh are of the steel disc type fitted with, twin solid tyres at the rear, are driven by dogs of ample dimensions.

Steering is of the usual worm, and segment type, .with the tiebar positioned behind the axle. The stub

axle steering arms are spigotted directly under the swivel pin Centres, the joints being of the ball type. The thrust of the swivel pin is taken through hardened cast steel buttons, ball thrusts not being employed, as pitting sometimes takes place on these when vehicles travel over bad roads. Plain bearings are employed in all the wheel hubs, the thrust washers for these being made of hard fibre.

Springing has been carefully attended to. The springs are long, with a large ntimber of Abroad leaves incidentally the driving torque is taken through those at the rear. The radiator, which.presents a bold appearance, is of the usual cast-alummium type, with cast header and bottom tank, provided with an exceptionally largetfilling orifice of the pocket-mouthed type, with a cap which requires no unscrewing.

All spur gears are constructed. of Keyser Ellison oil-toughened steel, as are also the driving shafts. A nice finish is 'given to the chassis by the employment of a pressed steel scuttle dash. We have not yet mentioned the frame.' This is of the usual channel-seetioil pressed steel type, in which

the side members are parallel throughout their length, but tapered towards the rear end. Tubular cross members are employed for carrying the clutch and brake; pedals and the gearbox, whilst a channel steel cross-member is positioned in line with the rear spring front brackets, and another Situated at the extreme end of the frame. This latter is strengthened by two struts reaching from its centre to the

side members. • The band brake operates, as usual, through steel rods on to drums contained in the rear wheels.

The wheelbase is 11 ft.' and the platform space behind the driver's seat 10 ft. 6 ins:

As regards the control, the hand brake lever and the gear change lever are situated in the usual position at the right of the driver.

The steering column is raked to an angle of about 50 degrees, and an 18 in. diameter steering wheel with 1 -in, section rim gives the driver easy control of the steering.

As soon as this chassis has been thoroughly tested, and any little rectifications which it may require have been attended to the Marathon willplaced on the market in quantities which Will assist in filling [tie large demand which exists for a vehicle of this capacity. •

We hope, later, to have an opportunity of testing the new "vehicle on.. the road, and will give our readersthe benefit of our experience in this conn ecti on. •