Mechanical Aids to Fartning.—III.

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

A Series of Four Articles Written with the Object of Assisting the Farmer to Decide upon the Best System to Employ to Meet his Own Particular Requirements. The Third of the Series Deals with Tractor•ploughing.

By a Contributor.

Direct Traction Ploughing, Direct ploughing, utilizing a tractor which traverses the ground and draws the plough after it, is by no means new in England. As mentioned before in article number one of this series, Charles Burrell and Sons, Ltd. designed an engine for direct plough ing in 1857. Ltd., then, development has b-een very slow, and not until the Ivel tractor was introduced, did manufacturers turn their attention again to this system of cultivating the soil. In Canada and the U.S.A., however, great tracts of land required cultivating, and engineers in those countries soon set to work to develop some mechanical power plants to

enable the farmers to place the land under cultivation; to-day machines are manufactured, the powers of which range from 7 to 60 traction h.p., and from 15 to 120 b.h.p.

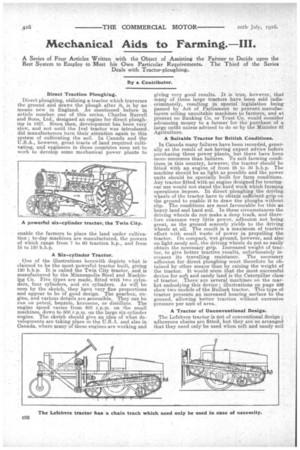

A Six-cylinder Tractor.

• One of the illustrations herewith depicts what is claimed to be the most powerful tractor built, giving 120 b.h.p. It is called the Twin City tractor, and is manufactured by the Minneapolis. Steel and Machinin,g Co. Five types are made, fitted with two cylinders, four cylinders, and six cylinders. As will' be seen by the sketch, they have very fine proportions and appear to be of good design. The gearbox, engine, and various details are accessible. They can be run on petrol, benzole, kerosene, or distillate. The engine speed varies from 800 r.p.m. on the small machines, down to 500 r.p.m. on the large six-cylinder engine. The sketch should give an idea of what developments are taking place in the U.S.A.-and also in Canada. where many of these engines are working and

giving very good results. It is true, however, that many of these large tractors have been sold indiscriminately, resulting in special legislation being passed by Act of Parliament to prevent manufacturers selling unsuitable machines to farmers, and at present no Banking Co. or Trust Co. would consider advancing money to a farmer for the purchase of a large outfit unless advised to do so by the Minister of

Agriculture. '

A Suitable Tractor for British Conditions.

In Canada many failures have been recorded, generally as the result of not having expert advice before purchasing these power plants, but there have been more successes than failures. To suit farming conditions in this country, however, the tractor should be fitted with an engine of from 25 to 20 b.h.p. The machine should be as light as possible and the power. units . should be specially built for farm conditions. Any tractor fitted with an engine designed for touring-. car use would not stand the hard work which farming operations impose. In direct ploughing the driving wheels of the tractor have to obtain sufficient grip on. the ground to enable it to draw the ploughs without slip. The conditions are most favourable for this an heavy land and hard soil. In these circumstances the driving wheels do not make a deep track, and therefore consume very little power, adhesion not being. great, as the ground scarcely yields to the driving. wheels at all. The result is a maximum of tractive effort with small waste of power in propelling the tractor. On compact, wet ground, however, and also on light sandy soil, the driving wheels do not so easily obtain the necessary grip. Increased weight of trac-. tor, to give better tractive results, unfortunately in.creases its travelling resistance. The necessary adhesion for direct ploughing must therefore be obtained by other means than by raising the weight of the tractor. It would seem that the most successful device for soft and sandy land is the Caterpillar class of tractor. Thereare several machines on the market embodying this device illustrations on page 429 show two models of the Bullock tractor. This type of tractor presents .an increased bearing surface to the ground, allowing 'better traction without excessive pressure per unit of area.

A Tractor of Unconventional Design.

The Lefebvre tractor is not of conventional design; adherence chains are fitted, but they are so arranged' that they need only be used when soft and sandy soil

is to be negotiated ; they may then be lowered by means of power-operated screws. These chains, being fitted on each side of the tractor, are lowered or raised in a few seconds simultaneously, and the peripheral speed of the driving wheels and the linear speed of the chains are the same. When in use the driving chains take 60 per cent. of the drive and the wheels take 40 per cent. When travelling on. good roads the chains are raised, the tractor then being driven by the hind. wheels.

The Caterpillar Type not the Best.

In all systems employing the chain-track, the wear is much greater than with road wheels, as it is impossible to lubricate the chains of these tractors in a satisfactory manlier, and it would almost appear that the most

efficient type of tractor for general farm work is that fitted with ordinary driving wheels, and not that utilizing a track-laying chain. The tractive efficiency of the average tractor on good footing ranges from 50 to 60 per cent., dropping sometimes to as low as 30 per cent. and occasionally reaching 70 per cent. In the trials at Winnipeg in 1909 seven single-cylinder gasolene tractors, fitted with comparatively small driving wheels but having wide tires, and weighing 299 lb. per inch in width of driving wheels and. 535 lb. per b. h.p. (as developed in an economy test), delivered in ploughing 61.4 per cent. of the lo.h.p. at the drawbar, and 50.8 per cent. when hauling—on the assumption that a comparison of separate brake and tractive tests is reliable.

Draft of Ploughs.

Sods differ greatly in their cohesive properties. The average draft of nine ploughs tested in five different kinds of soil was as follows :—Loamy sand 227 lb., sandy loam 250 lb., moory soil 280 lb., strong loam 440 lb., blue clay 661 lb. Each plough was cutting furrows 5 ins, deep and 9 ins. wide. The difference be tween extremes is 194 per cent. The above tests of plough draft were inade in England some years ago.

Tractive Effort and Horse-power for Ploughing.

In ploughing with ordinary equipment the best tractor is the one which will deliver the largest percentage of its b. h.p. at the drawbar, all other things being equal. In other words a ploughing tractor should have the highest possible tractive efficiency consistent with other vital features. Tractive horsepower is ascertained by noting the speed of travel and determining the resistance of the load by means of a traction dynamometer. This instrument consists fundamentally of a calibrated spring which may be attached between the engine and its load ; the tension of the spring causes it to move a pointer upon a dial which is graduated to show the resistance in pounds. A knowledge of the distance travelled in a given time, together with the resistance, enables the tractive horse-power to be calculated. For example, a tractor moving at/a Tate of two miles per hour travels in one hour 10,560 ft., or 176 ft. per minute. If the average resistance or draft is 7500 lb., then in one minute the tractor does 176 by 7500, or 1,320,000 foot-pounds of work. This divided by 33,000 gives 40 h.p. Taking into consideration the power loss in transmission, a. rough estimate of the power required from a, tractor is 5 h.p. or 6 h.p. per furrow. A suitable engine should be light, with wheels about 6 ft. diameter and wide tires fitted with spudlets or spikes to enable the machine to get the necessary adhesion in soft land. There are many machines being manufactured in England which re suitablefor certain .farms : these will effect striking economies and multiply the efficiency of every• machine and implement on the farm not operated by hand power. The self-binder is a great invention, so also is the drill, the mower, the thrashing machine, disc harrow and gang plough. Each in its particular way has played an important part in the development of farming, yet the usefulness of each is

limited by the cost and efficiency of the power employed to operate it. If these machines can be operated. by cheap mechanical power, the utility and value of each as a piece of mechanism are immediately increased. With a well-designed tractor on a farm for which it is suitable, a great saving in time and labour can be effected.

Disadvantages of Direct Ploughing.

Some of the disadvantages of direct traction are that 50 per cent, of the horse-power is required to move the tractor over the land, and on certain farms where the land is of a heavy clay nature the tractor will consolidate the soil, the result being smaller crops, and it may possibly do more harm than good. Even when a self-binder only has been worked where the land is too damp the next season's crop shows where the travelling wheel of the binder has been. The direct tractors will not work in very wet weather, and can only be used to advantage when the best conditions prevail. Much difficulty is also experienced in ploughing hilly fields and land on hill sides. Crossploughing cannot be performed so satisfactorily as is the case with the cable sets of tackle, or even with the self-contained motor plough. The headlands are much larger with the direct sets of tackle than with any other system of mechanical power plants, and require much time for ploughing them after the main part of the field is ploughed. However, the farmer, in adopting mechanical ploughing by direct traction, if proper conditions have been considered and his land is suitable, will save a lot of drudgery and hard work. The next article will be on self-contained modern ploughs.