A New Producer-gas Plant

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

for road transport

PRODUCER-GAS as a . fuel for commercial vehicles is no new idea, but, hitherto, it has received very little encouragement in this country. An apparatus differing markedly from previous plants is now in an advanced state of development and is already demonstrating its capa

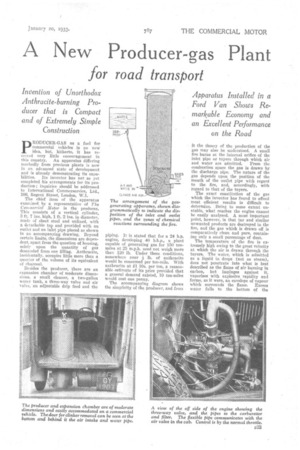

bilities. Its inventor has not as yet completed his arrangements for its production; inquiries should be addressed to International Commerservice, Ltd., 106, Regent Street, London, W.1. The chief item of the apparatus examined by a representative of The Commercial Motor is the producer. This consists of a vertical cylinder, 3 ft. 7 ins. high, 1 ft. 2 ins, in diameter, made of sheet steel and unlined, with a detachable top and provided with an outlet and an inlet pipe placed as shown in an accompanying drawing. Beyond certain limits, the dimensions are dependent, apart from the question of housing, solely upon the quantity of gas demanded from one filling. Anthracite, incidentally. occupies little more than a quarter of thc volume of its equivalent of charcoal.

Besides the producer, there are an expansion chamber of moderate dimensions, a small cleaner, a two-gallon water tank, a three-way valve and air via% e. an adjustable drip feed and the piping. It is stated that for a 24 h.p. engine, developing 40 b.h.p., a plant capable of generating gas for 150 tonmiles at 25 m.p.h. need not weigh more than 120 lb. Under these conditions,

somewhere near lb. of anthracite would be consumed per ton-mile. With anthracite at £1. 10s. per ton, a reasonable estimate of its price provided that a general demand existed, 10 ton-miles would cost one penny.

The accompanying diagram shows the simplicity of the producer, and from

it the theory of the production of the gas may also be understood. A small fire burns at the internal orifice of the inlet pipe or tuyere through which air and water are admitted. From the combustion space the gas is drawn by the discharge pipe. The nature of the gas depends upon the position of the mouth of the outlet pipe with regard to the fire, and, accordingly, with regard to that of the tuyere.

The exact constitution of the gas which the inventor has found to afford most efficient results is difficult to determine. Being to some extent unstable, what reaches the engine cannot be easily analysed. A most important point, however, is that tar and similar unwanted products are destroyed in the fire, and the gas which is drawn off is comparatively clean and pure, containing only a small percentage of dust.

The temperature of the fire is extremely high owing to the great velocity at which the air is drawn through the tuyere. The water, which is admitted as a liquid in drops (not as steam), does not penetrate into what is best described as the flame of air burning in carbon, but impinges against it, vaporizes with explosive rapidity and forms, as it were, an envelope of vapour

which surrounds the flame. Excess water falls to the bottom of the producer, whence it can contribute to the circulation maintaining the envelope. The region surrounding the zone of vapour is composed of aqueous matter, in some form ranging from the vaporous state above, precipitating rain, to the pool of liquid below.

The inner zones are that at the tip of the tuyere, where no combustion takes place, that surrounding it, where the fiercest temperatures obtain, and where presumably COn is formed, the cooler zone, in which the COI changes to CO, and the heat is less, and that in which the water vapour is present and where the gas-making reaction is completed.

Thus it is clear that heat is confined in a small space and the surrounding anthracite remains quite cool—indeed, on the occasion of our trial, after running for some two hours, no part of the producer, more than•a few'inches above the level of the discharge pipe, felt warmer than the hand could barely detect. The pipe, expansion chamber and cleaner were but little hotter.

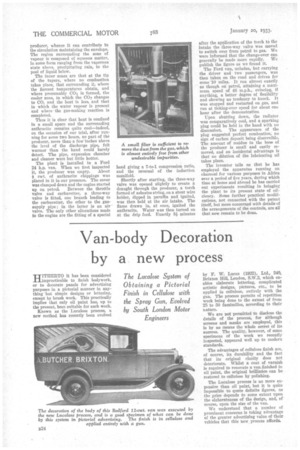

The plant is installed in a Ford 24 h.p. van. When we first inspected it, the producer was empty. About cwt. of anthracite clippings was placed in it in our presence. The cover was clamped down and the engine started up on petrol. Between the throttle valve and carburetter, a three-way valve is fitted, one branch leading to the carburetter, the other to the gassupply pipe ; in the latter is an air valve. The only other alterations made to the engine are the fitting of a special head giving a 7-to-1 compression ratio, and the reversal of the induction manifold.

Shortly after starting, the three-way valve was opened slightly to create a draught through the producer, a torch formed of asbestos string, on a stout wire holder, dipped in paraffin and ignited, was then held at the air intake. The flame drawn in, at once, ignited the anthracite. Water was then turned on at the drip feed. Exactly 84 minutes after the application of the torch to the intake the three-way valve was moved to switch over from petrol to gas. We were informed that the change-over can generally be made more rapidly. We publish the figure as we found it.

The Ford van, unladen, but carrying the driver and two passengers, was then taken on the road and driven for some-10 miles. It ran almost exactly as though on petrol, attaining a maximum speed of 48 m.p.h., evincing, if anything, a better degree of flexibility and showing no tendency to knock. It was stopped and restarted on gas, and ran at ticking-over speed for about one hour after the demonstration

Upon shutting down, the radiator was comparatively cool, and a sparking plug could be held in the hand with no discomfort The appearance of the plug suggested perfect combustion, no sign of carbon deposit being discernible. The amount of residue in the base of the producer is small and easily removed, and an incidental advantage is that no dilution of the lubricating oil takes place.

The inventor tells us that he has employed the apparatus running on charcoal for various purposes in Africa over a period of five years, during which time at home and abroad be has carried out experiments resulting in bringing the plant to its present stateof efficiency. Some further practical modifications, not connected with the patent itself, but more concerned with details of the arrangements of the controls, are all that now remaia to be done.