CONTROLLED BUYING Speeds Up Body Production

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

AMAIN factor in any industrial organization is purchasing, upon which will depend to a large extent quality promptitude of delivery and estimate of ultimate costs. This is particularly noticeable in bodybuilding, in which a large proportion of the components, such as electmal fittings, destination-indicating equipment and seating, is purchased in the finished state. Production rates and delivery schedules are greatly influenced by the availability of such components at the time required.

The scheduled execution .-)f design is alsO a controlling influence, because if the buyer does not receive specification details in time, he is faced with the problem of attempting to rush delivery. Purchasing, therefore, should be closely linked with designing and only full co-operation between the two functions will ensure a steady flow of production.

It is intended to recommend procedure suited to a company of which the policy is to manufacture a wide range of passenger-vehicle bodies. These would be made to operators' specifications. A large variety of designs is required, amounting to anything from 15 to 20 types, especially when there is a multiplicity of models of chassis. Each order thus requires special attention and preparation, and considerable detailed work is involved before the purchasing department can be given particulars of what is requirm:.

The problem, however, is not so complex as it might appear to be, if there be insistence on a systematic, yet flexible, organization of purchasing, the personnel for Which have the ability to anticipate varying requirements. The first essentials are the delivery programme, upon which reasonable assurance can be given that the rotation of delivery will be maintained, and a comprehensive list of parts common to all types of body. It is surprising, even in the case of a production policy of the kind described, how many components are common to all the specifications. By means of the systematic analysis and a suitable approach to operators, the number of common components can, in fact, be increased.

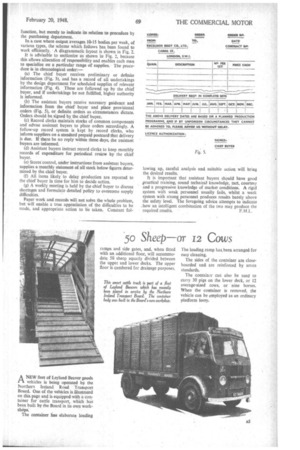

When the list of common parts and the general programme are available for the purchasing department, other components are then requisitioned by the estimating section, prepared instructions being given to the purchasing department. To guide the design department, the purchasing section supplies a comprehensive list of. customers' requirements of the past, with some. indication of delivery period and current prices (Fig.)). This list is brought up to date periodically, following close study of market fluctuations, Obviously, a concern manufacturing a wide variety of types cannot carry large stocks of components, such as seat frames, windscreen and window panes, destination indicators

and so on, and such items have to be catered for in the supply schedule. Accurate forecasts of supplies of these items determine the delivery period and the purchasing department should advise the sales side as to dates on Which materials will be available, whilst the design and manufacturing side provide information as follows:—

(a) Period required for designers to complete other work in hand.

(b) Period required for the designing department to prepare all working drawings, as well as instructions to the purchasing and manufacturing sides.

(c) Delivery forecasts for materials.

(d) Actual time for production, after receipt of all drawings. manufacturing instructions and materials. Experience has indicated that if all manufacturing instructions and materials be available at the right time, the period of production can be determined to close limits. Thus if a, b and c can be identified with their scheduled periods, it will be possible to keep to the promised date of delivery. Whilst it is impossible entirely to separate the design department from the purchasing department, it is not intended to show here how a design department should function, but merely to indicate its relation toprocedure by the purchasing department

In a case where output averages 10-15 bodies per week, of various types, the scheme which follows has been found to work efficiently. • A diagrammatic layout is shown in Fig. 2.

It is advisable to sectionize as shown in Fig. 2, because this allows allocation of responsibility and enables each man to specialize on a particular range of supplies. The procedure is in chronological order:—

(a) The chief buyer receives preliminary or definite information (Fig. 3), and has a record of all undertakings by the design department for scheduled supplies of relevant information (Fig. 4). These are followed up by the chief buyer, and if undertakings be not fulfilled, higher authority is informed.

(b) The assistant buyers receive necessary guidance and information from the chief buyer and place provisional orders (Fig. 5), or definite orders as circumstances dictate. Orders should be signed by the chief buyer.

(c)Record clerks maintain stocks of common components and advise assistant buyers to place orders accordingly. A follow-up record system is kept by record clerks, who inform suppliers on a standard prepaid postcard that delivery is due. If there be no reply within three days; the assistant buyers are informed.

(d) Assistant buyers instruct record clerks to keep monthly records of expenditure for periodical review by the chief buyer.

(e) Stores control, under instructions from assistant buyers, supplies a monthly statement of all stock below figures determined by the chief buyer.

(f) All items likely to delay production are reported to the chief buyer in time for him to decide action.

(g) A weekly meeting is held by the chief buyer to discuss shortages and formulate detailed policy to overcome supply difficulties.

Paper work and records will not solve the whole problem, but will enable a true appreciation of the difficulties to be made, and appropriate, action to Ve taken. Constant fol lowing up, careful analysis and. suitable action will bring the desired results.

It is important that assistant buyers should have good practical training, sound technical knowledge, tact, courtesy and a progressive knowledge of market conditions. A rigid system with weak personnel usually fails, whilst a weak system with strong personnel produces results barely above the safety level. The foregoing advice attempts to indicate ,how an intelligent combination of the two may produce the required results. F. ft?. L