Spring Anchorage Giving Constant Deflection Rate

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

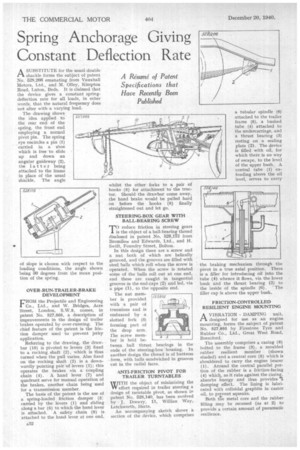

A SUBSTITUTE for the usual double

shackle forms the subject of patent No. 528,266 emanating from Vauxhall Motors, Ltd., and M. 01ley, Kimpton Road, Luton, Beds. It is claimed that the device gives a constant springdeflection rate for all loads, in other words, that the natural frequency does not alter with a varying load.

The drawing shows the idea applied to the rear end of the spring, the front end employing a normal pivot pin. The spring eye encircles a pin (1) carried in. a shoe which is free to slide up and down an angular guideway (2), the latter being attarled to the frame in place of the usual shackle. The angle of slope is chosen with respect to the loading conditions, the angle shown being 30 degrees from the mean position of the spring.

OVER RUN-TRAILE R RAKE DEVELOPMENT

FROM the Projectile and Engineering Co., Ltd., and W. Bridges, Acre Street, London, S.W.8, comes, in patent No. 527,668, a description of improvements in the design of trailer brakes operated by over-running. The chief feature of the patent is the friction damper used to prevent jerky application.

Referring to the drawing, the drawbar (10) is pivoted to levers (3) fixed to a rocking shaft (2), which is thus turned when the pull varies. Also fixed on the rocking shaft (2) is a downwardly pointing pair of levers (1); this operates the brakes •via a coupling chain (4). A hand lever (7) and quadrant serve for manual operation of the brakes, another chain being used for a transmission member.

The basis of the patent is the use of a spring-loaded friction damper (5; carried by the levers (1) and sliding along a bar (6) to which the hand lever is attached. A safety chain (9) is attached to the hand lever at one end, whilst the other forks to a pair of hooks (8) for attachment to the tractor. Should the drawbar come away, the hand brake would be pulled hard on before the hooks (8) finally straightened out and let go.

STEERING-BOX GEAR WITH BALL-BEARING SCREW

ersrithe object of a ball-bearing thread reduce friction in steering gears

disclosed in patent No. 528,173 from Eromilow and Edwards, Ltd., and H. Swift, Foundry Street, Bolton.

In this design there are a screw and a nut both of which are helically grooved, and the grooves are filled with steel halls which roll when the screw is operated. When the screw is rotated some of the balls roll out at one end,. and these are caught in tangential grooves in the end-caps (2) and led, via a pipe (1), to the opposite end.

The nut mem ber is provided with a pair of trunnions and is embraced by a slotted fork (3) forming part of the drop arm. The screw member is held between bail thrust bearings in the ends of the steering-box housing. In another design the thread is of buttress .form, with bans sandwiched in grooves cut in the radial faces.

ANTI-FRICTION PIVOT FOR TRAILER TURNTABLES

WITH the object of minimizing the effort required in trailer steering a design of turntable pivot, as shown in patent No. 528,140, has been evolved by J. Drewry, 11, Willian Way, Letchworth, Herts.

An accompanying sketch shows a section of the device, which comprises the braking mechanism through the pivot in a true axial position. There is a filler for introducing oil into the. tube (4) whence it flows, via the lower bush and the thrust bearing (3) to the inside of the spindle (6). ' The filler cap is above the upper bush.

FRICTION-CONTROLLED RESILIENT ENGINE MOUNTING

AVIBRATION DAMPING unit, designed for use as an engine mounting, forms the subject of patent No. 527,895 by Firestone Tyre and Rubber Co., Ltd., Great West Road, Bren tford.

The assembly comprises a casing (6) bolted to the frame (3), a moulded rubber resilient member (shown shaded) and a central core (5) which is shouldered to carry the engine bearer (I). Around the central parallel portion of the rubber is a friction-facing (4) whic13, as it rubs against the casing, absorbs energy and thus provides a damping effect. The lining is lubricated with colloidal graphite in castor oil, to prevent squeaks. Both tRe metal core and the rubber filling may be recessed (as at 2) to provide a certain amount of pneumatic resilience.