HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from . fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenue, "London, E.C. 1."

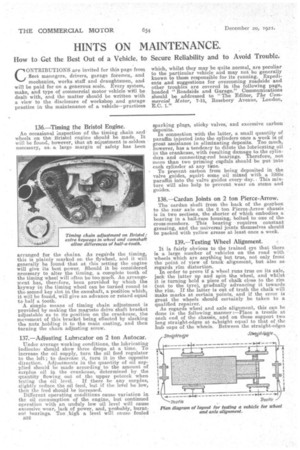

136.—Timing the Bristol Engine.

An occasional ;inspection of the timing chain and wheels on the Bristol engine should be made. It, will be found, however, that an adjustment is seldom necessary, as a large margin of safety has been arranged for the chains. As regards the timing, this is plainly marked on the flywheel. and it will generally be found that at this setting the engine will give it best power. Should it be considered necessary to alter the timing, a complete tooth of the timing wheel will often be too much. An arrangereent has, therefore, been provided by which the key-way in the timing wheel can be turned round to the second key slot in the camshaft, a position which, it will be found, will give an advance or retard equal to half a tooth. A simple means of timing chain adjustment is provided by making the magneto drive shaft bracket adjustable as to its position on the crankcase, the movement of this bracket being effected by slacking the nuts holding it to the main casting, and then turning the chain adjusting screw.

137.—Adjusting Lubricator on 2 ton Autocar.

Under average working conditions, the lubricating indicator should show three drops at a time. To increase the oil supply, turn the oil feed regulator to the left; to decrettse it, turn it in the opposite direction. Adjustments in the quantity of oil supplied should be made according to the amount of surplus oil in the crankcase, determined by the quantity flowing out of the upper petcock when testing the oil level. If there be any surplus, slightly reduce the oil feed, but if the lelrel be low, then the feed should be increased. Different operating conditions cause variation in the oil consumption of the engine, but continued operation with an unduly low oil level will cause excessive wear, lack of power, and, probably, burntout hearings. Too .high a level will cause fouled n32 sparking plugs, sticky valves, and excessive carbon deposits. In connection with the latter, a small quantity of paraffin injected into the cylinders once a week is of great assistance in eliminating deposits. Too much, however, has a tendency to dilute the lubricating oil in the crankcase, with resulting damage to the cylinders and connecting-rod bearings. Therefore' not more than two priming cupfuls should be put into each cylinder at any time. To prevent carbon from being deposited in the valve guides, squirt some oil mixed with a little paraffin into the valve guides every. day. , This mixture will also help to prevent wear on stems and guides.

138.—Cardan Joints on 2 ton Pierce-Arrow.

The cardan shaft from the back of the gearbox to the rear axle on the 2 ton Pierce-Arrow chassis is in two sections, the shorter of which embodies a bearing in a ball-race housing, bolted to one of the cross-members. This bearing requires constant greasing, and the universal joints themselves should be packed with yellow grease at least once a week.

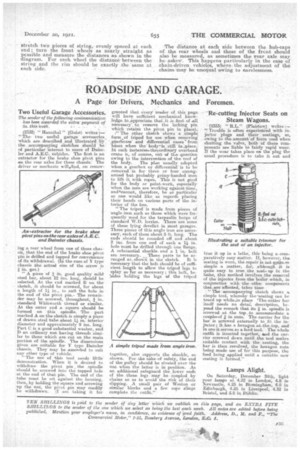

139.—Testing Wheel Alignment.

It is fairly obvious to the trained eye that there is a large number of vehicles on the road with wheels which are anything but true, not only from the point of view of track alignment, but also asregards rim distortion. In order to prove if a wheel runs true on its axle, jack the latter up and spin the wheel, and whilst it is turning hold a piece of chalk close to the rim (not to the tyre), gradually advancing it towards the rim. If the latter is out of truth the chalk will make marks at certain points, and if the error is great the wheels should certainly be taken to a qualified repairer. As regards wheel and axle alignment, this can be done in the following manner :—Place a trestle at each end of the chassis, and on these support two long straight-edges at a.height equal to that of the hub caps of the whdels. Between the straight-edges stretch two pieces of string, evenly spaced at each end; turn the front wheels as nearly. straight as possible and measure the distances as shown in the diagram. For each wheel the -distance.between the string and the rim should he exactly the same at each side.

The distance at each side between the hub-caps of the rear wheels and those of the front should also be measured, as sometimes the rear axle may be askew. This happens particularly in the case of chain-driven vehicles, where, the adjustment of the chains may be unequal awing to carelessness.