For DRIVERS, MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week all others 'are paid for at the rate o) a penny a lsne, with an published, Mention your employer's name, in confidence, Commercial Motor," 7-15, Bos

to the sender of the best letter which we publish on this page ; alloWance for photographs. All notes are edited before being as evidence of good faith, Address, D., M. and F., "The ebery Avenue, London, E.G. 1.

Lamps Alight— Light your lamps at 4.25 in London, 4.41 in Edinburgh, 4.11 in Newcastle, 4.26 in Liverpool? 4.27 in Birmingham, 4.35 in Bristol, and 5.20 in Dublin.

Pressure-tight Joints.

The sender of the following communication has been awarded the Ws. prize this week.

[1812] " S.C." ()ELKS. "Chatham writes :— " The making of pressure-tight joints is an important function of the engineer. The less experieneed mechanic readers of your D.M. and F. pages may therefore find the following notes of use. " For most purposes, if we neglect those joints which must for _various reasons be made without any intermediate jointing material, the selection of the latter is half the battle. I think that the choice must lie between Klingmit and Perrnanite :they are immeasurably superior to any other which is on the market. Fdr water joints red lead is very suitable ; when used for gas or steam, however, it ie apt slowly' to powder and gradually to be blown out. Shellac makes a good joint for most fluids ; it is very difficult to unmake a joint„ of this material, though, as well as being very hard to remove from the flanges, etc., when the joint must be renewed.

"Wire-woven asbestos sheeting, well treated with mineral oil and graphite, or mineral oil and blacklead, also makes a good all-round joint.

"The great advantage of Klingerit, or Permanite, is that it can be used over and over again. It should he smeared on one side with a little boiled linseed oil, and on the other with mineral grease and graphite (or blacklead). The oil serves to gum one side of the jointing material to the corresponding face of the joint, and the graphite allows the other side to come freely away, when required, without injury.

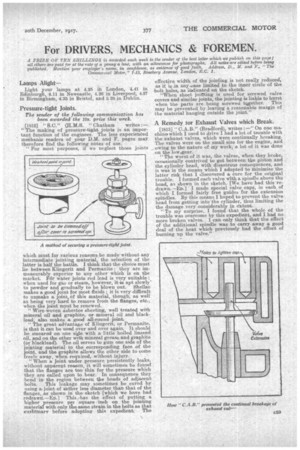

"When a joint under pressure persistently leaks, without apparent reason, it will sometimes be found that the flanges are too thin for the pressure which they are called upon to bear. In consequence they bend in the region between the heads of adjacent bolts. This leakage may sometimes be cured by using a joint of rather less diameter than that of the flanges, as shown in the sketch [which we have had redrawn.—En.] This ;'has the effect of putting a higher pressure pei square inch on the jointing material with only the same strain in the bolts as that customary before adopting this expedient. The

effective width of the jointing is net really reduced, as it is in any eiase limited to the inner circle of the bolt holes, as indicated on the sketch. "When sheet jointing is used for screwed valve covers and similar joints, the jointing is liable to burst when the parts are being screwed tagether. This may be prevented by leaving a reasonable margin of the material hanging outside the joint."

A Remedy for Exhaust Valves which Break.

L15131 " C.A.B." (Bradford), writes :—" On one machine' which I used to drive I had a lot of trouble with the exhaust valves, which were continually breaking. The valves were on the small size for the engine, and owing to the nature of My work, a lot of it was done . on the lowl,gear. "The worst of it was, the valves, when they broke, ot=sionally contrived to get between the piston and the cylinder head, with disastrous consequences, and it was in the means which I adopted to minimize the latter risk that I discovered a cure for the original trouble. I formed each valve with a spindle above the head, as shown in the sketch.. [We have had this -redrawn. —En.] I made special valve caps, in each of which I formed fairly free guides for the extension spindles. By this means I hoped to prevent the valve head from getting into the cylinder, thus limiting the the damage very considerably in axtent. "To my surprise, I found that the whole of the trouble was overcome by this expedient, and I had no more broken valves. I can only think that the effect of the additional spindle was to carry away a good deal of the heat which previously had the effect of burning up the valve."